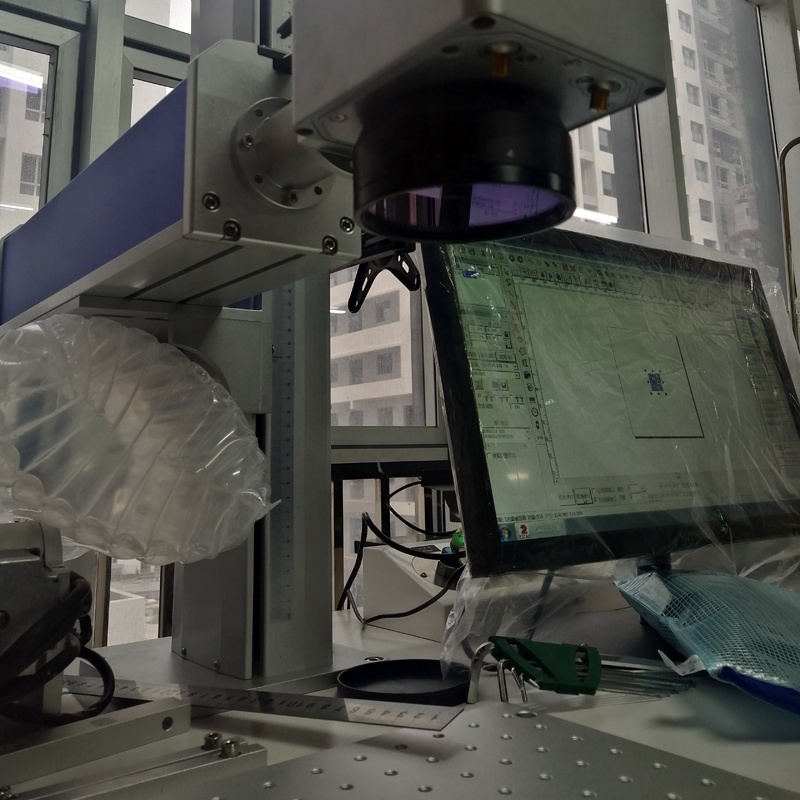

In today’s rapidly developing technological era, the 3D laser marking machine, with its unique technical advantages, has triggered a marking revolution in numerous fields.

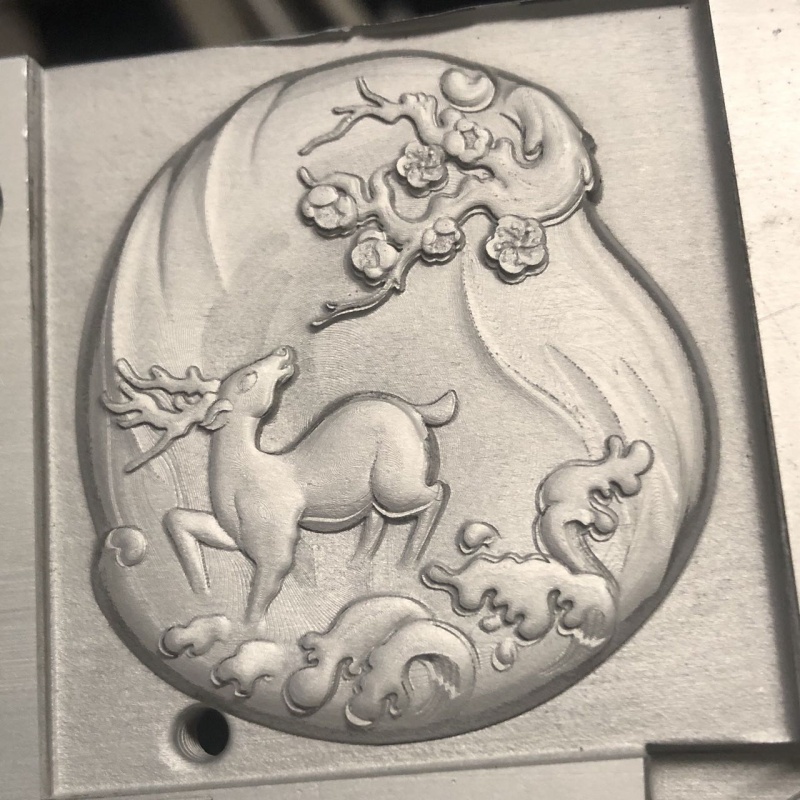

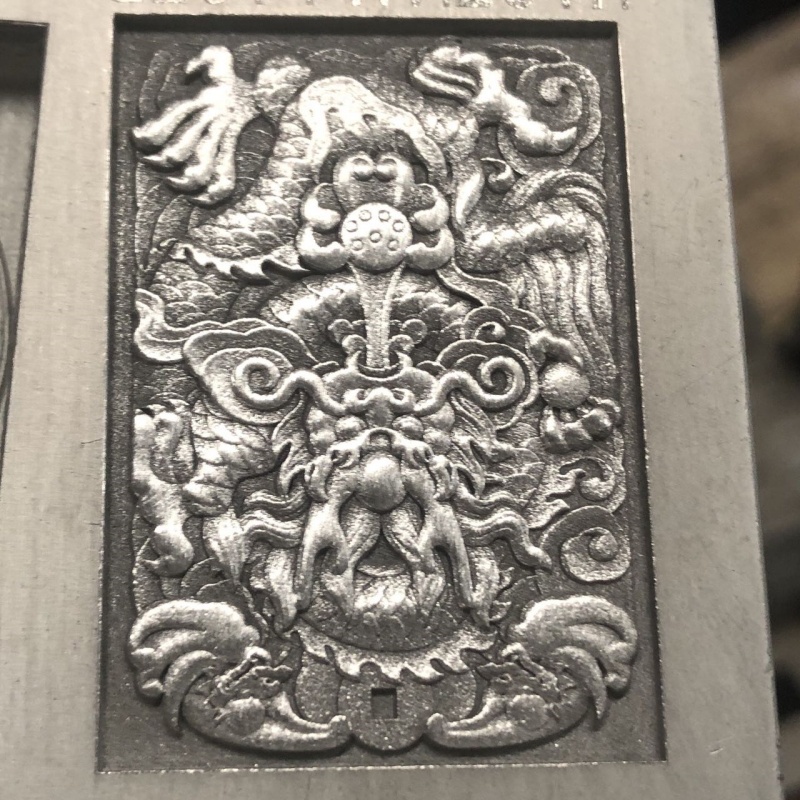

Different from traditional 2D marking, which can only present patterns on a flat surface, 3D laser marking can, through precise control of the laser focusing depth, form three-dimensional marks with depth, a sense of relief, and a sense of hierarchy on the surface of materials. This three-dimensional effect greatly enhances the visual appeal and artistic value of the marks. In the jewelry industry, 3D laser marking can carve three-dimensional brand logos, patterns, or personalized designs on the surfaces of materials such as gold, silver, and diamonds, making the products more unique and of high-end quality, and effectively enhancing the market competitiveness of the products.

The 3D laser marking machine has remarkable advantages. Its high precision allows it to achieve mark details accurate to the micrometer level. Whether it’s delicate text, complex patterns, or tiny logos, they can all be perfectly presented. In terms of material adaptability, it can be widely applied to various materials such as metals, plastics, ceramics, and glass, meeting the diverse needs of different industries. Moreover, 3D markings are not only aesthetically pleasing but also possess stronger wear resistance and anti-counterfeiting properties, significantly increasing the added value of products.

In practical applications, the 3D laser marking machine is ubiquitous. In the automotive manufacturing industry, it can mark three-dimensional production numbers, QR codes, and other information on key components such as engine blocks and transmission casings. These marks are clear and durable, facilitating product traceability and quality control. At the same time, in the personalized customization of automotive interiors, the 3D laser marking machine can carve unique patterns and designs on components such as seats and dashboards, creating an exclusive driving experience for users. In the jewelry industry, the 3D laser marking machine can perform ultra-fine three-dimensional markings on precious jewels like diamonds and gold, such as brand logos, carat weights, and unique commemorative patterns. This not only does not affect the beauty and value of the jewelry but also enhances the product’s recognition and anti-counterfeiting function. In addition, in the medical device field, the 3D laser marking machine can mark clear product information and patient-specific data on implantable devices, ensuring medical safety and traceability.

Looking to the future, with the deep integration of technologies such as artificial intelligence and big data with the 3D laser marking machine, its intelligence and automation levels will be further enhanced. Meanwhile, new breakthroughs will also be achieved in aspects such as energy conservation, environmental protection, and miniaturization, enabling it to better adapt to different production environments and requirements. The 3D laser marking machine is bound to play an important role in more emerging fields, continuously empowering the high-quality development of the manufacturing industry and sculpting a more wonderful three-dimensional world.