ATC CNC router for wood working machine with straight-line tool-changing processing center is mainly used for the production and processing of cabinet bodies and kitchen door panels in furniture. The equipment is equipped with 9 KW automatic tool-changing spindle and a 12-capacity stacked tool magazine, allowing for fast drilling, cutting, grooving, milling, engraving, and other operations with a single clamping.

ATC CNC routers offer the highest efficiency and versatility in the industry. It has an automatic tool change function and is mainly used for woodworking, signage making and manufacturing. This feature greatly reduces manual intervention, resulting in increased productivity. Users will love the precision and ability to easily handle complex designs through advanced software integration and solid construction. With its powerful ATC spindles, large worktables and super friendly interface, this is the ideal CNC for both hobby and professional Settings.

Under the gantry liner tool changer magazine , will not be due to diagonal offset of the tool store position is wrong, greatly saving the tool change time, optional circle tool change

Adjustable, four-position follow blowing dust removal structure, vacuum effect 90%+.

Z-axis guide slide block is equipped with a pressing device to prevent the gap between the slide block and the guide rail and maintain the processing accuracy of the equipment for a long time.

Multiple oil grooving devices are connected to the device to prevent grease dripping from fouling board parts and aging cables.

| Parameter | Specification | |||

| Working stroke | X axis | 0~2000 mm | Control System | Taiwan Syntec / Delta |

| Y axis | 0~4000 mm | Spindle | Aircooling9.0KW | |

| Z axis | 0~400 mm | Tool magazine | 12pcs servo tool changer | |

| Max.Feed rate | X axis speed | 65m/min | Driver system | Taiwan Syntec / Delta |

| Y axis speed | 65m/min | Reducer | Japan Shimpo/France Moto | |

| Z axis speed | 20m/min | Gear Rack | Taiwan helical rack | |

| Positional accuracy | ±0.05mm | Guide rails | Taiwan Guide liner rails | |

| Working accuracy | ±0.1mm | Inverter | HPMONT | |

| Working speed | 0~20m/min | Main electrical element | France Schneider | |

| Machine size | 2500*4500*2300mm | Main switch button | Germany Siemens | |

| Machine weight | 5000KGS | Table structure | Double layout PVC vacuum table | |

| Working voltage, pressure, power | 3PH AC380V/50Hz、≥0.65MPa、20.5KW(without dust collect) | |||

| Other standard | Double bag dust collect、7.5KW water vacuum pump ,tool holder ect. | |||

ATC CNC Router with linear tool changer machines ( we also called ATC CNC router or ATC wood

working machine) can install 4 pcs、6pcs、8 pcs、12pcs automatic liner tool changers.It is

widely used in different industries.

For cabinet panel furniture industry,most company choose ATC wood working machine with

the loading & unloading function .Wood working samples for cutting, engraving drilling for

cabinet panel furniture with nesting function.

Other Industry application:

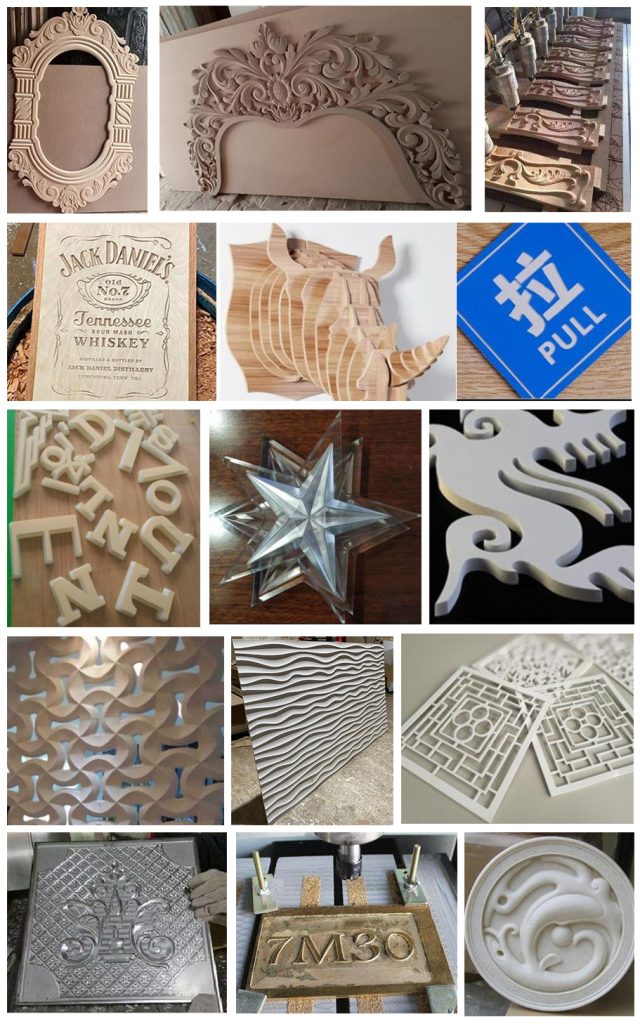

1. Wood furniture industry:wave plate, fine pattern, antique furniture,wooden door,screen,craft

sash,composite gate,interior door, sofa legs,headboards,game cabinets,office table sewing

machines table etc.

2. Advertising industry: advertising identification,sign making, acrylic engraving and

cutting,crystal word making,blaster molding and other advertising materials derivatives making.

3. Crafts making

4. Architectural models

phone: +8613791007598

[email protected]