CNC technology: Through programming, automatic processing is achieved, which greatly improves production efficiency. At the same time, the CNC system also has a variety of bending modes to meet the bending needs of different shapes and angles. Synchronous torque technology: Through precise torque control, it ensures that the plate is evenly stressed during the bending process to avoid problems such as deformation or distortion. This technology also enables the equipment to adapt to plates of different thicknesses and materials, improving the versatility and flexibility of the equipment. Safety protection measures: The equipment has a variety of safety protection measures, such as overload protection, emergency stop, etc., to ensure the safety of operators. Simple maintenance: The maintenance of the equipment is relatively simple, which reduces the cost of use.

“Shortcut” touch navigation

10.1″ industrial-grade TFT touch screen

Up to 4-axis control (Y1, Y2 + 2 auxiliary axes)

Deflection compensation control with mold/material/product library

Large arc programming function

Advanced Y-axis control algorithm, can control both closed-loop valves and open-loop valves.

Internal storage capacity 1 GB

USB peripheral interface

USB data backup/restore

Profile-53TL offline programming software

The back gauge uses a CNC system to control the servo drive motor transmission (X, R axis), driving the ball screw linear guide to move up and down and forward and backward synchronously

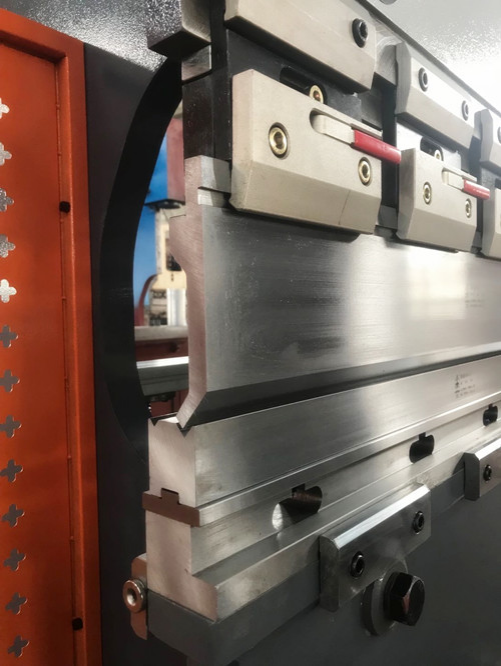

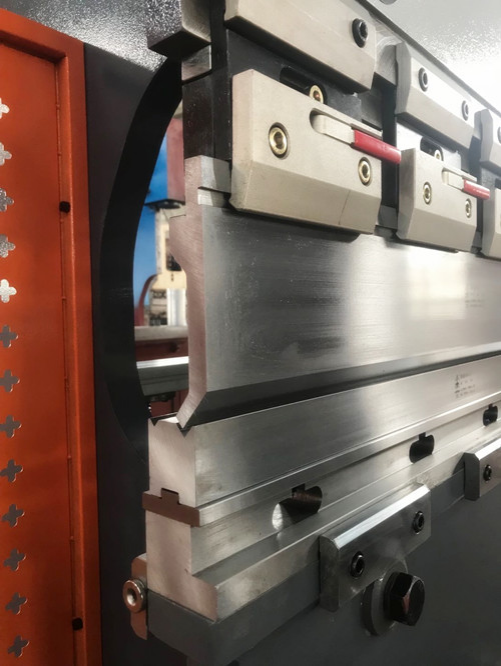

Quick release mold

| Serial number | project | Parameter Value | unit |

| 1 | Nominal force | 1100 | KN |

| 2 | Workbench length | 3200 | mm |

| 3 | Column spacing | 2700 | mm |

| 4 | Throat Depth | 400 | mm |

| 5 | Slider stroke | 200 | mm |

| 6 | Maximum opening height | 500 | mm |

| 7 | Main motor power | 8.7 | kW |

| 8 | Fast download speed | 170 | mm/s |

| 9 | Working speed | 12 | mm/s |

| 10 | Return speed | 160 | mm/s |

| 11 | Slider repeat positioning accuracy | ±0.01 | mm |

| 12 | Back gauge stroke | 600 | mm |

| 13 | Maximum running speed of back gauge | 200 | mm/s |

| 14 | Back gauge repeat positioning accuracy | ±0.05 | mm |

| 15 | Dimensions | 3650x1750x2700 | mm |

| 16 | weight | 6500 | Kg |

During the bending process of the workpiece, the force generated when the plate is bent causes the lower surface of the slider to deform concavely due to the maximum force on the oil cylinders at both ends of the slider. The deformation of the middle part of the slider is large. In order to eliminate the adverse effects of slider deformation, it is necessary to compensate for the deflection deformation of the slider. The convex worktable mechanical compensation mechanism causes the middle part of the worktable to produce upward elastic deformation to offset the deformation of the machine tool slider, ensure the accuracy of the machining joint surface, and improve the accuracy of the workpiece. The bending machine uses mechanical compensation for the worktable. When the slider stops at the top dead point, the CNC system automatically calculates the compensation amount based on the thickness, length, and selected mold of the bending material. The system module controls the forward and reverse direction of the motor to adjust the compensation deformation, and then feeds back the changes in the position of the upper and lower pads through a potentiometer.

phone: +8613791007598

[email protected]