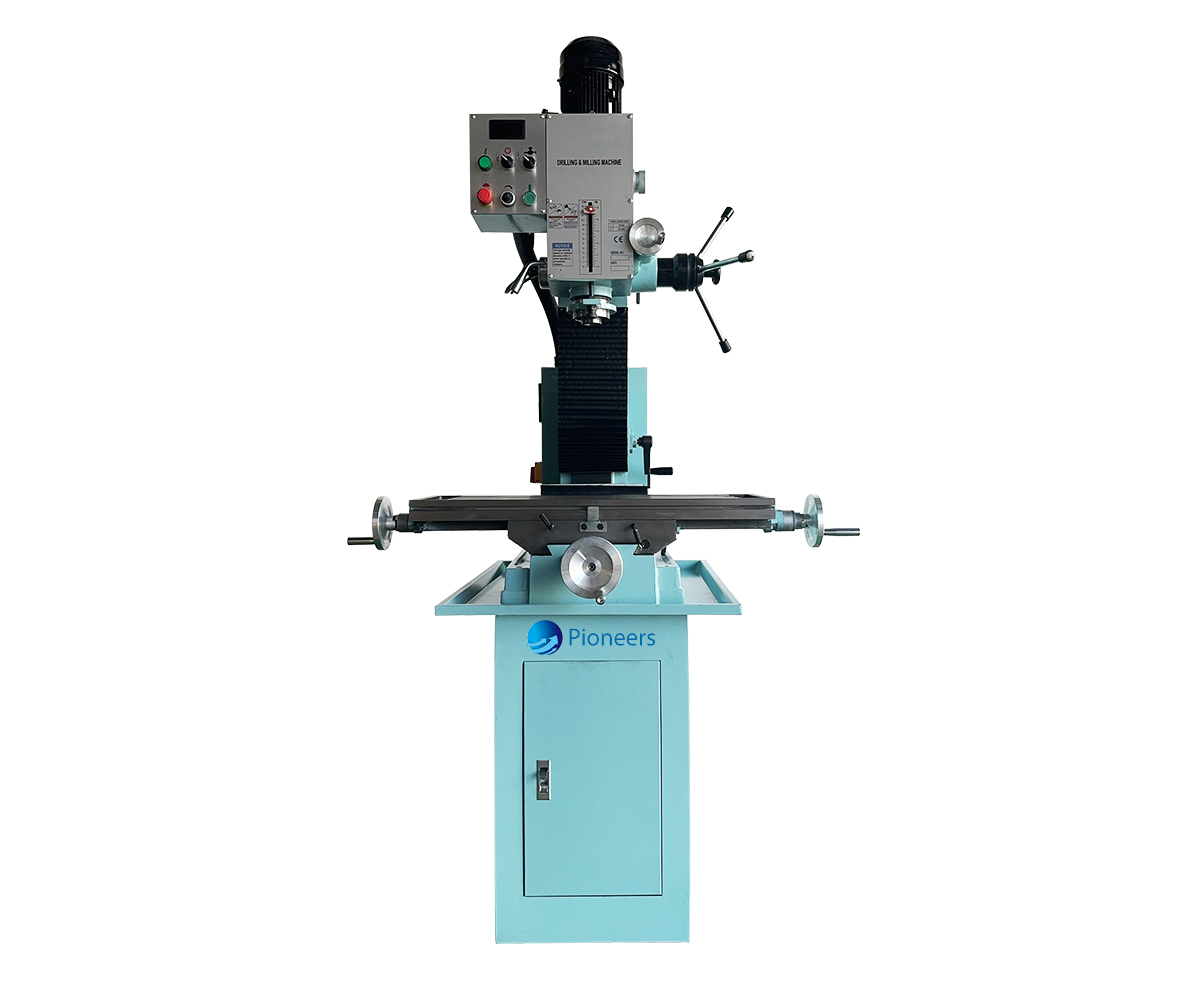

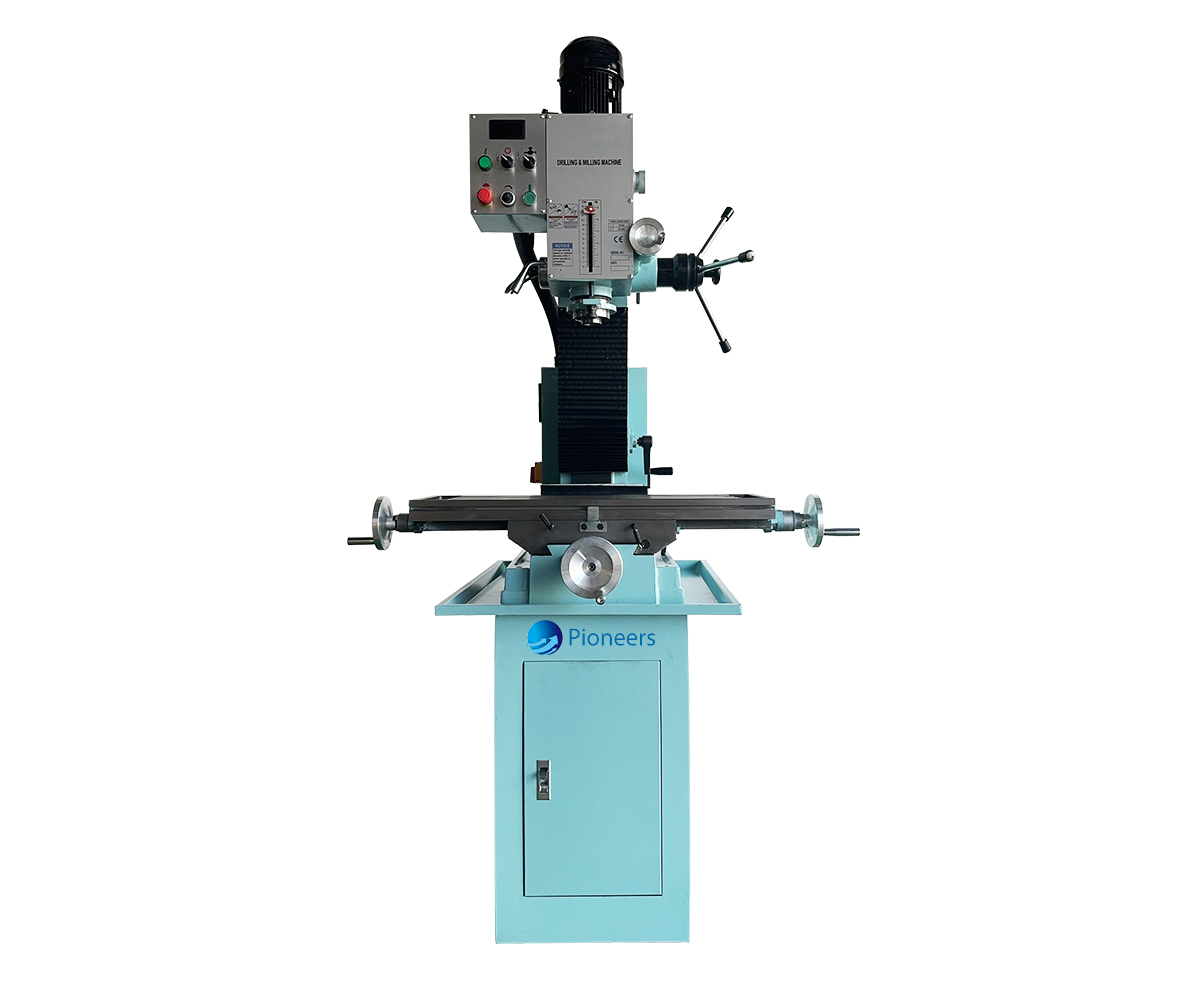

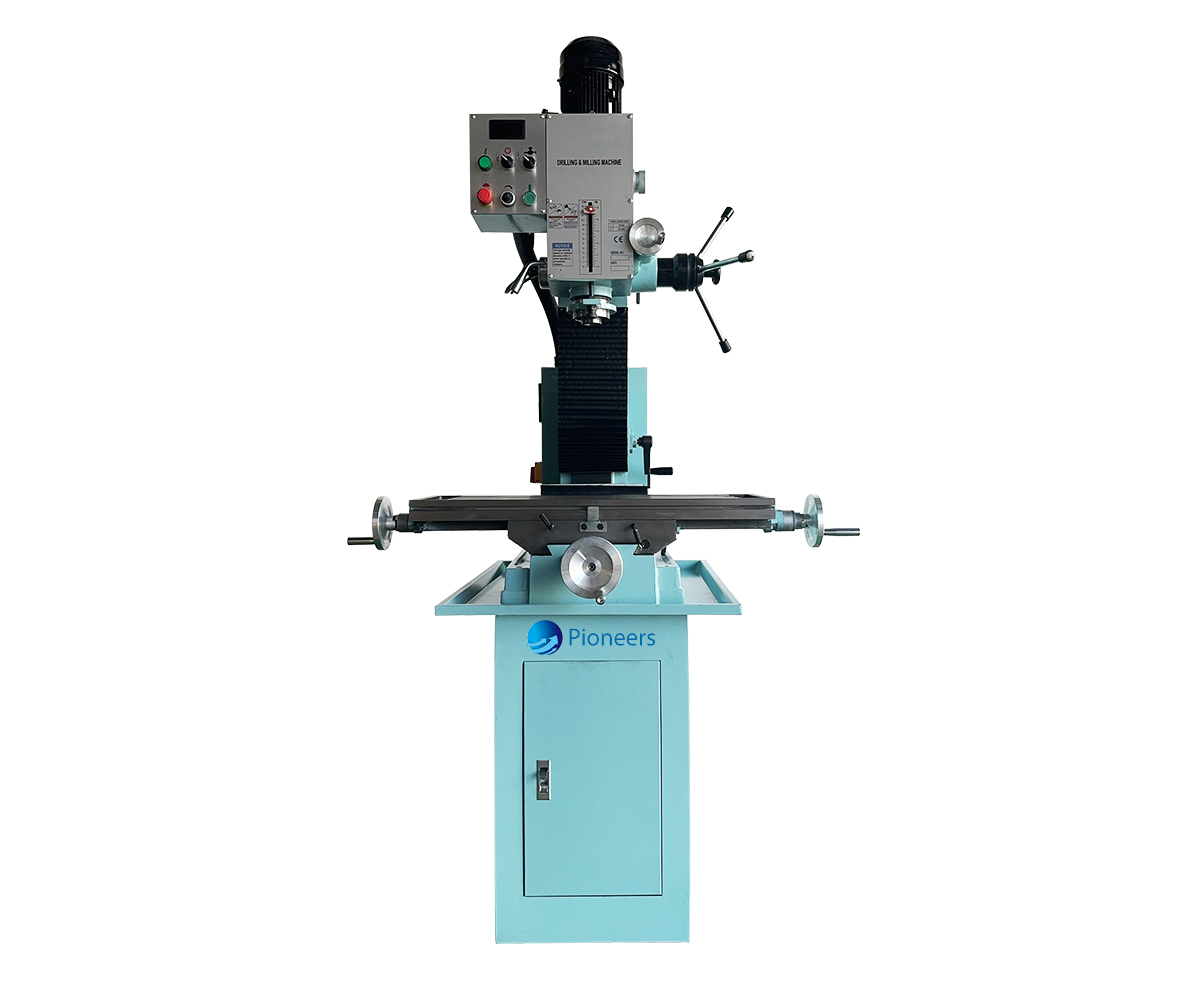

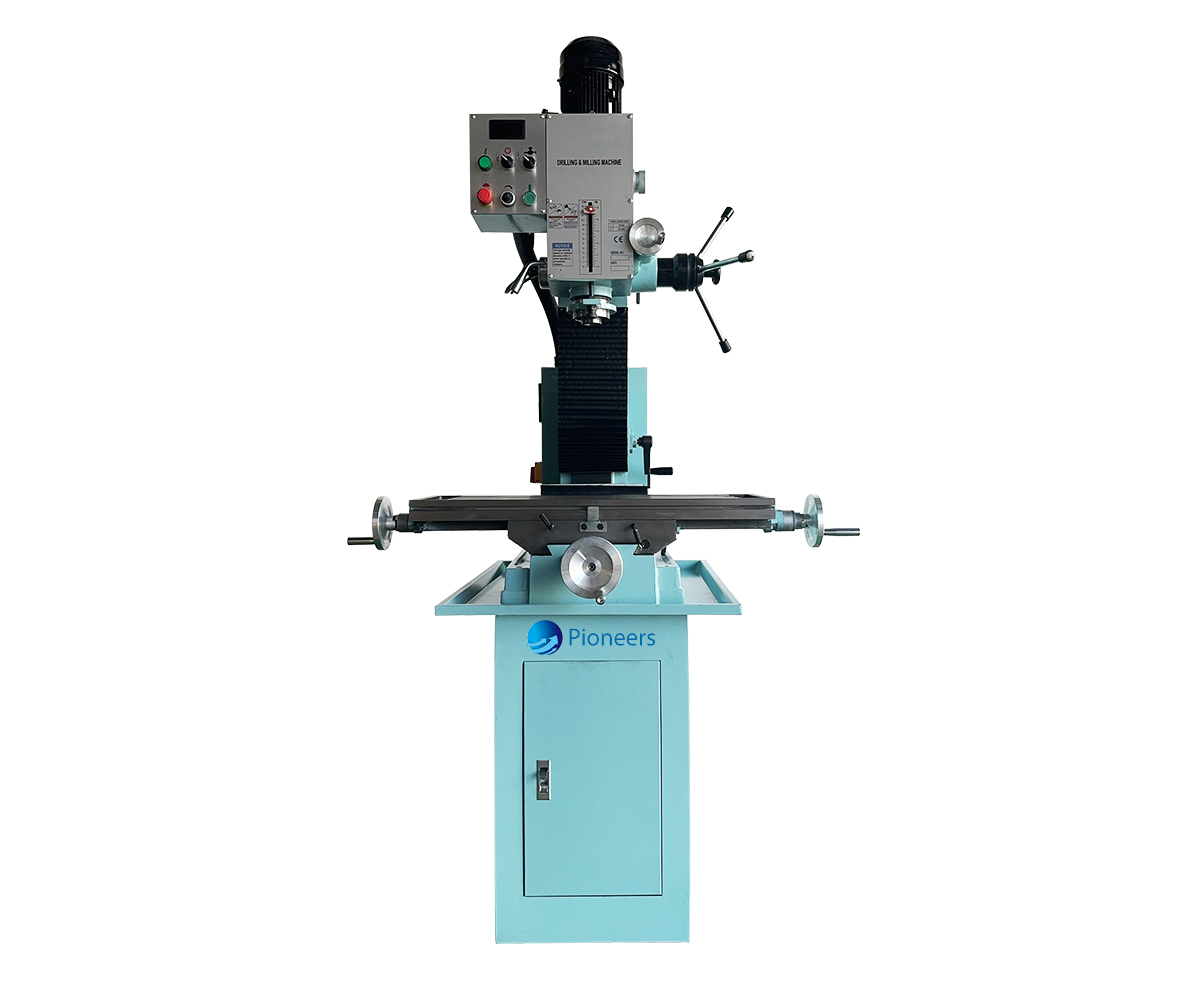

The drilling & milling machine is a multifunctional machine tool that has both cutting and milling functions and is widely evaluated in industries that require metal cutting processing.

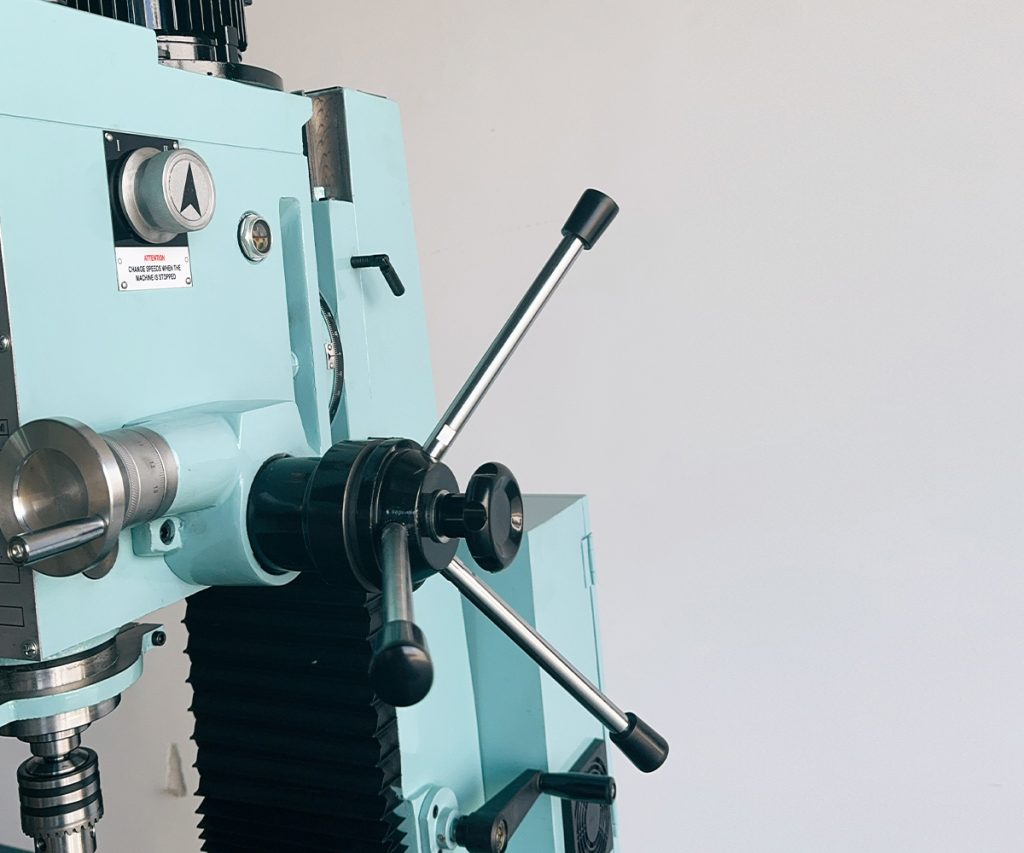

Gear Drilling Milling Head

Gear type drilling milling head, hardenedprecision ground gears with high rigidityHead swivels ±45° vertically

Motor

Powerful motor improvesprocessing efficiency.2.2kw big motor asoptional.

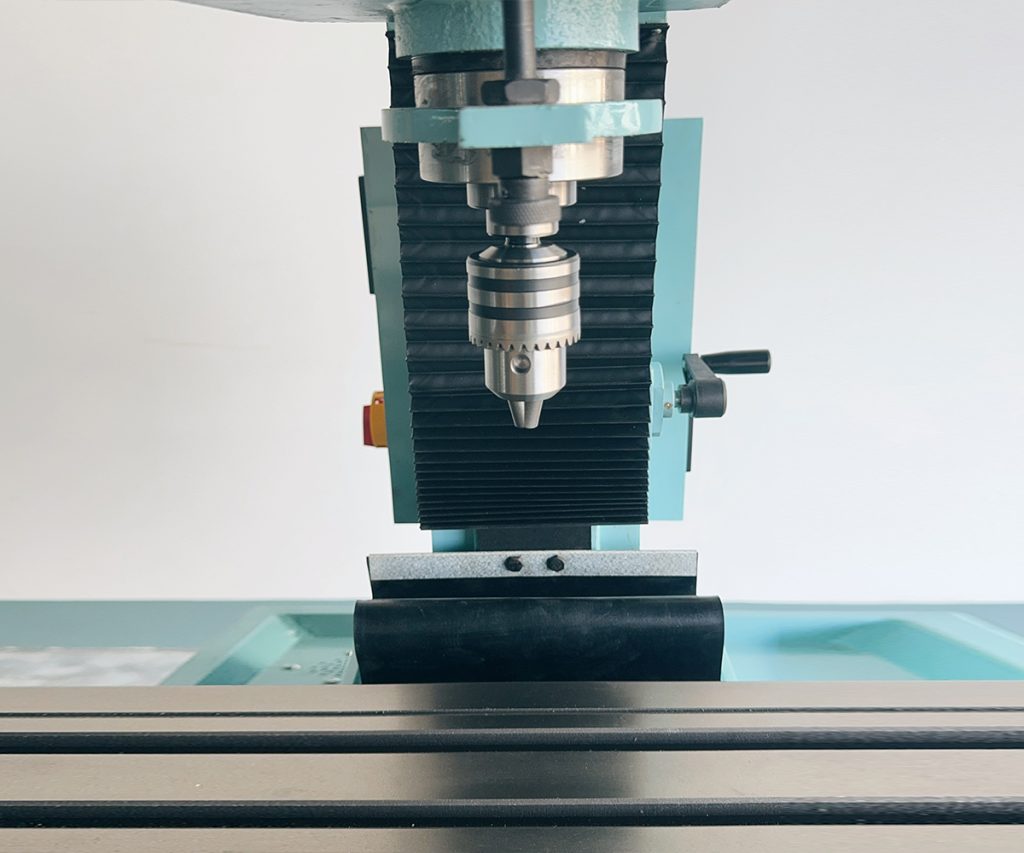

Spindle

The spindle adopts energyconsuming braking. Withlarge starting torque, rapidstop and reliableSpindle taper: MT3/MT4/R8

Spindle Feed Handle

Adjust the drilling and millingmachine head. Automatic toolmovement improves efficiencyand accuracy

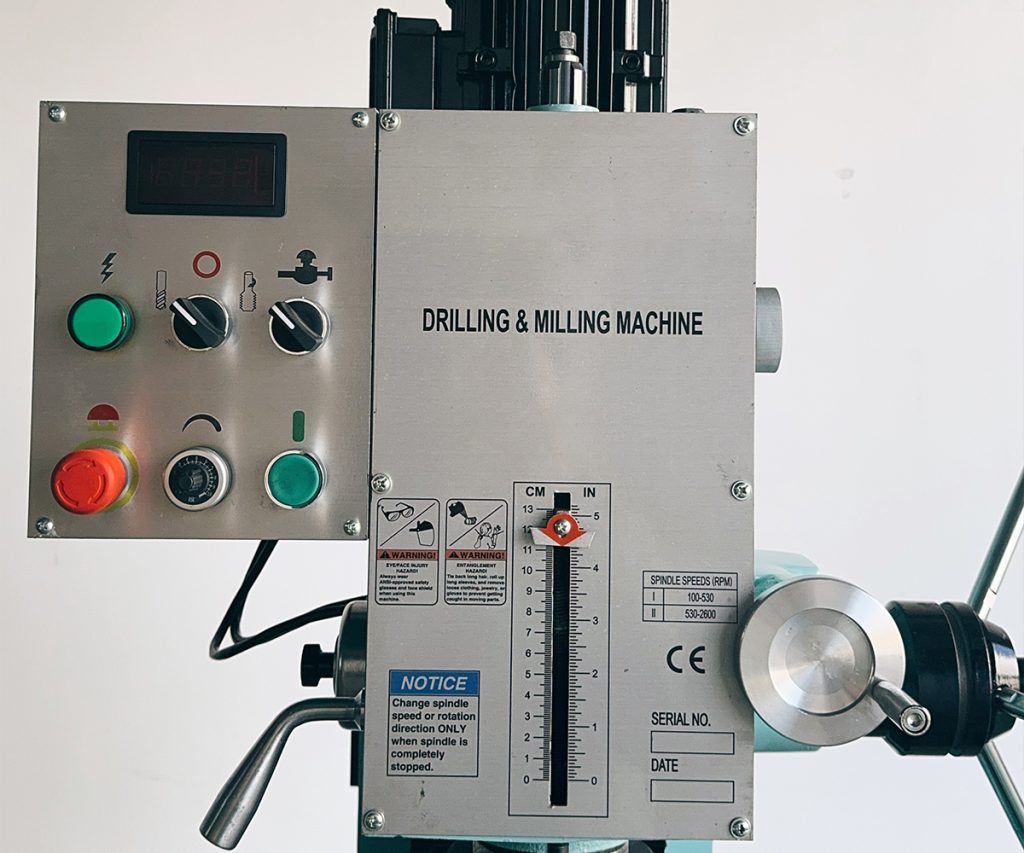

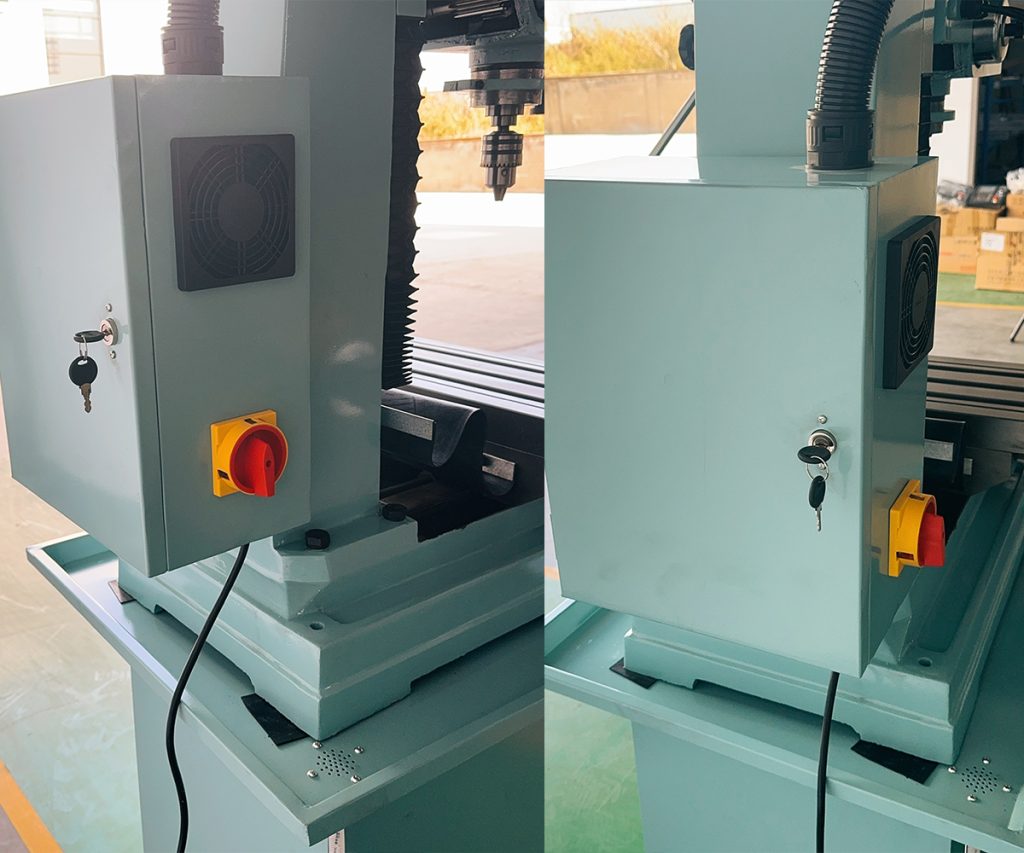

Electrical Box

It is easy to open and closethe circuit and has a veryhigh level of protection.

| Model | ZAY7032V/1 ZAY7040V/1 ZAY7045V/1 |

| Max. drilling capacity | 32mm/40mm/45mm |

| Max. tapping capacity | 20mm |

| Max. face mill capacity | 63mm/80mm/80mm |

| Max. end mill capacity | 20mm/32mm/32mm |

| Max. distance from spindle nose to table | 450mm |

| Min. distance from spindle axis to column | 260mm |

| Spindle travel | 130mm |

| Spindle taper | MT3 MT4 or R8 |

| Range of spindle speed(2 steps) | 100-530, 530-2800rpm |

| Auto-feeding steps of spindle | 3 |

| Auto-feeding value of spindle | 0.06-0.30mm/r |

| Swivel angle of headstock | ±45° |

| Table size | 800×240mm |

| Forward and backward travel of table | 175mm |

| Left and right travel of table | 500mm |

| Motor power(D.C) | 1.5kw(2HP) |

| N.W/G.W | 325/375kgs |

| Packing size(LxWxH) | 770×880×1160mm |

| Loading amount/20″ container | 36pcs |

One set only.

Yes, we have professional engineers and designers. We can provide OEM services

Yes, we can design and manufacture according to your specific requirements.

phone: +8613791007598

[email protected]