/Fiber-Laser-Cutting-Machine-for-Metal-Sheet-And-Pipe-pd46307014.html

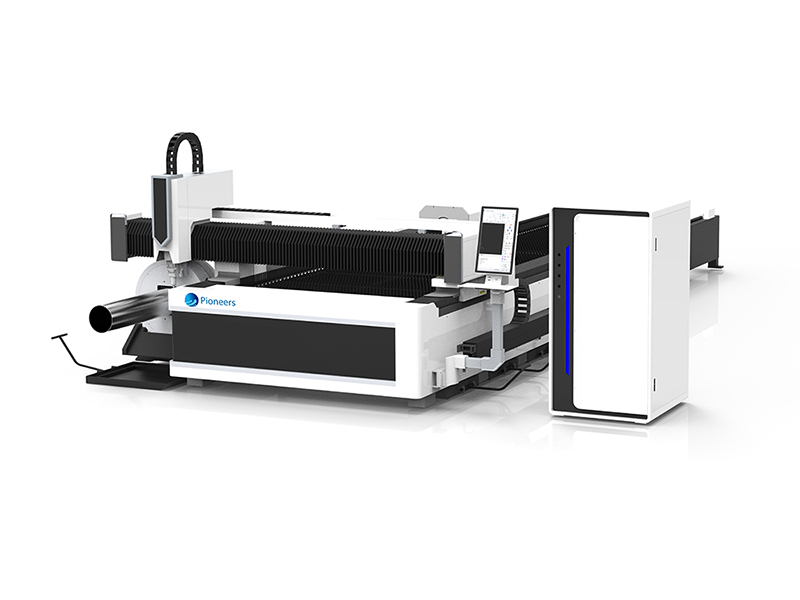

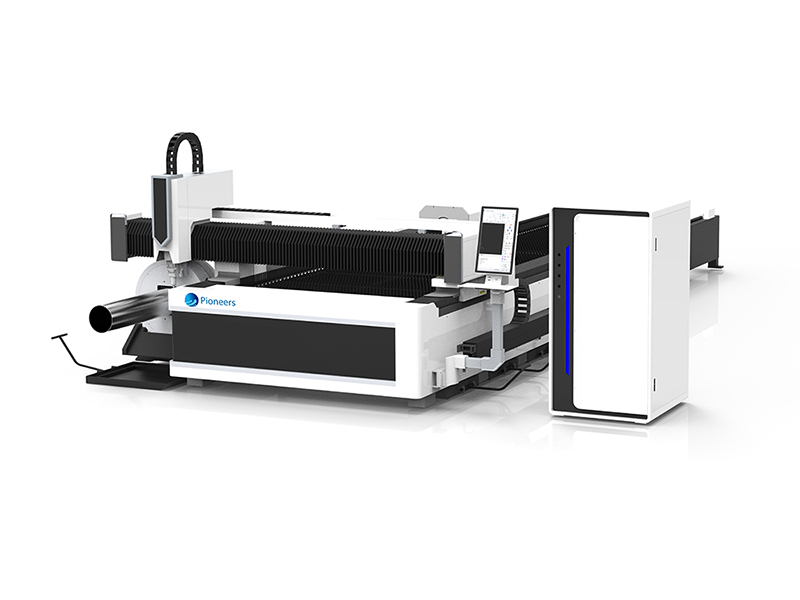

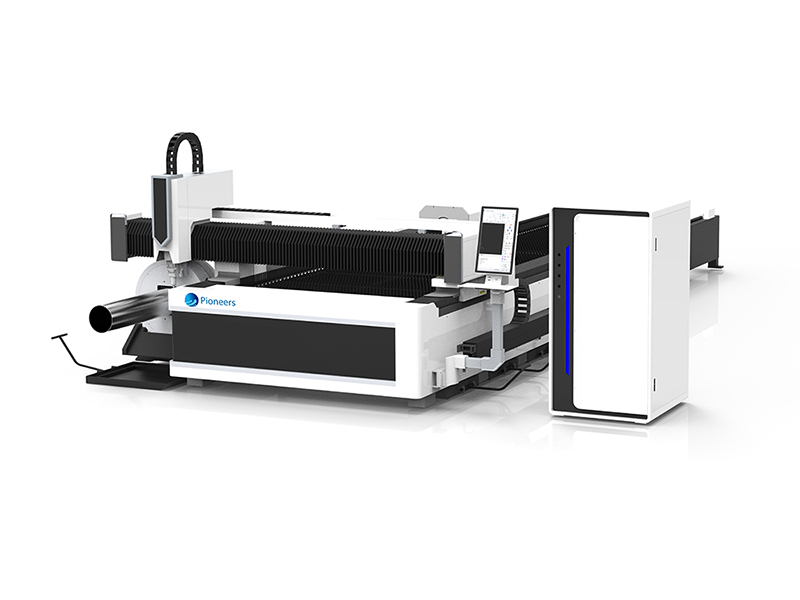

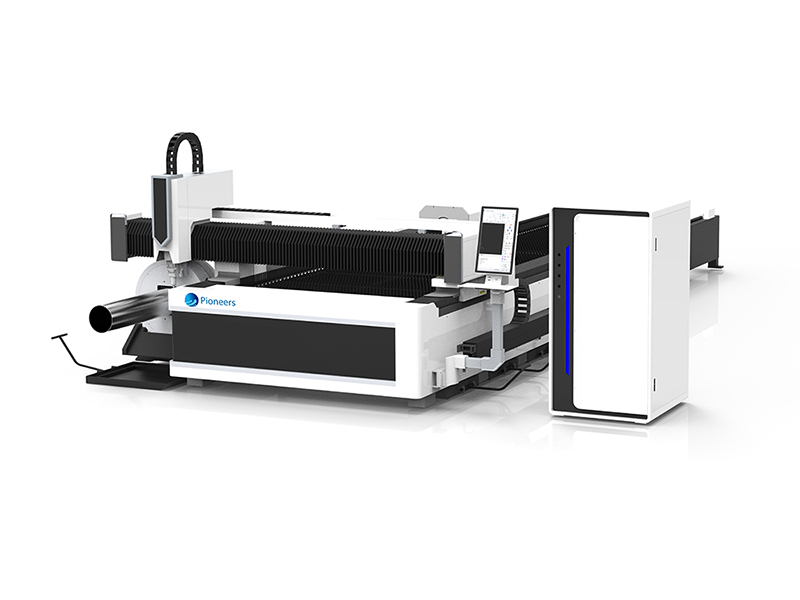

¡ø3m/6m tube cutting length

¡øpneumatic chunk up to 350mm

¡øPlate welding machine body

¡øSuper light aluminum gantry with highest hardness

|

Raycus laser source Good heat resistance, high beam quality, Good maintenance, fault diagnosis and interlocking function performance |

|

Raytools laser cutting head (auto focus) A variety of optical fiber laser interface, and various fiber lasers for adaptation, collimating lens and focusing lens have water-cooled structure, which can withstand high power. conductive to high anti-reflective material cutting and thick plate explosion-proof hole sputtering.drawer type lens makes lens replacement faster. |

|

|

HIWIN guide rail Linear guide design, carrying capacity and rigidity, have higher arc groove and structure optimization, compare with other similar products, radial equal rated load,reverse radial and lateral direction, and centering automatic to absorb installation errors.long-life high-speed, high precision and smooth linear motion. |

|

Cypcut cutting control system Integrated file read, design, processing, and output control as a whole, a set of software can complete whole process from design to machining. Software provides extensive laser cutting process parameters. |

|

|

Yaskawa servo motor Stable operation, good controllability, quick response, high sensitivity, strict non-linearity index of mechanical characteristics and regulation characteristics, reliable operation, low maintenance requirement. |

|

TongFei industrial water chiller Water chiller of fiber cutting machine¡¯s water system adopts double temperature water chiller, one is cooling laser and the other is cooling cutting head. |

|

|

Independent computer It has vertical screen display, different from the traditional horizontal screen display with good response speed, higher contrast, wider view, low power consumption as well as high resolution. In addition, it possesses high brightness levels and lower reflectively as well as solid glass panel sturdiness and durability. |

|

Remote control handle It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation. |

|

|

SMC/Airtac pneumatic components High degree of standardization, high-end market share, wide channels. Short ordering cycle, good quality and long service life,relatively small volume, convenient design. |

|

Automatic height adjustment Raise system adjust the focal length automatically according to the height of the plate. |

|

|

Machine model |

PLF3015LNR |

|

Laser power |

1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

|

Dimensions |

4600*2450*1700mm |

| Tube diameter | Up to 350mm |

|

Working area |

3000mm x 1500mm |

|

Repeat positioning accuracy |

±0.02mm |

|

Maximum speed |

120m/min |

|

Maximum acceleration |

1.5G |

|

Specified voltage and frequency |

380V/50Hz/60Hz/60A |

Machine checking team to check every parts follow the purchase order after sales done, double check to mke sure every parts all will ship machine together ,and take pics save in the machine folder

Wrap all the machine parts with bubble film & plastic film.Insert necessary anti friction & collision pad at the corner. Set all the small parts on the machine bed to save space.

Machines are packed into wooden pallets and loaded into containers

¡ø3m/6m tube cutting length

¡øpneumatic chunk up to 350mm

¡øPlate welding machine body

¡øSuper light aluminum gantry with highest hardness

|

Raycus laser source Good heat resistance, high beam quality, Good maintenance, fault diagnosis and interlocking function performance |

|

Raytools laser cutting head (auto focus) A variety of optical fiber laser interface, and various fiber lasers for adaptation, collimating lens and focusing lens have water-cooled structure, which can withstand high power. conductive to high anti-reflective material cutting and thick plate explosion-proof hole sputtering.drawer type lens makes lens replacement faster. |

|

|

HIWIN guide rail Linear guide design, carrying capacity and rigidity, have higher arc groove and structure optimization, compare with other similar products, radial equal rated load,reverse radial and lateral direction, and centering automatic to absorb installation errors.long-life high-speed, high precision and smooth linear motion. |

|

Cypcut cutting control system Integrated file read, design, processing, and output control as a whole, a set of software can complete whole process from design to machining. Software provides extensive laser cutting process parameters. |

|

|

Yaskawa servo motor Stable operation, good controllability, quick response, high sensitivity, strict non-linearity index of mechanical characteristics and regulation characteristics, reliable operation, low maintenance requirement. |

|

TongFei industrial water chiller Water chiller of fiber cutting machine¡¯s water system adopts double temperature water chiller, one is cooling laser and the other is cooling cutting head. |

|

|

Independent computer It has vertical screen display, different from the traditional horizontal screen display with good response speed, higher contrast, wider view, low power consumption as well as high resolution. In addition, it possesses high brightness levels and lower reflectively as well as solid glass panel sturdiness and durability. |

|

Remote control handle It employs a wireless controller, with free control clamp pressure for easy control and operation, which can reduce pipe deformation. |

|

|

SMC/Airtac pneumatic components High degree of standardization, high-end market share, wide channels. Short ordering cycle, good quality and long service life,relatively small volume, convenient design. |

|

Automatic height adjustment Raise system adjust the focal length automatically according to the height of the plate. |

|

|

Machine model |

PLF3015LNR |

|

Laser power |

1000W 2000W 3000W 4000W 6000W 8000W(Optional) |

|

Dimensions |

4600*2450*1700mm |

| Tube diameter | Up to 350mm |

|

Working area |

3000mm x 1500mm |

|

Repeat positioning accuracy |

±0.02mm |

|

Maximum speed |

120m/min |

|

Maximum acceleration |

1.5G |

|

Specified voltage and frequency |

380V/50Hz/60Hz/60A |

Machine checking team to check every parts follow the purchase order after sales done, double check to mke sure every parts all will ship machine together ,and take pics save in the machine folder

Wrap all the machine parts with bubble film & plastic film.Insert necessary anti friction & collision pad at the corner. Set all the small parts on the machine bed to save space.

Machines are packed into wooden pallets and loaded into containers

phone: +48 501 944 934

[email protected]