In the fields of modern manufacturing and creative design, laser etching machines are playing an increasingly important role. With its high precision, flexibility, and wide applicability, it has become an indispensable processing tool in many industries. Today, let’s uncover the mystery of laser etching machines together.

I. The Principle of Laser Etching

Laser etching machines use high-energy-density laser beams to irradiate the surface of materials, causing the materials to melt, vaporize, or undergo chemical reactions instantaneously, thus forming predetermined patterns, texts, or marks on the material surface. Simply put, it’s like using an extremely fine “light knife” to carve on the material.

This process is based on the thermal effect and photochemical effect of lasers. When the laser beam is focused on the material surface, the light energy is rapidly converted into heat energy, causing the temperature of the irradiated area to rise sharply, reaching the melting point or even the boiling point of the material. The material melts and vaporizes rapidly and is removed instantaneously. In some heat-sensitive materials, lasers can also trigger photochemical reactions, changing the chemical properties of the material surface to achieve the etching effect.

II. Application Fields of Laser Etching Machines

Electronics Industry: In circuit board manufacturing, laser etching machines can accurately etch fine circuit lines, meeting the requirements of miniaturization and high precision of electronic products. At the same time, it can also be used for chip marking, coding of electronic components, etc., providing convenience for the production and traceability of electronic products.

Jewelry Industry: Laser etching machines can carve exquisite patterns, texts, and personalized logos on materials such as metals and gemstones. Whether creating unique wedding rings or adding artistic value to jewelry, laser etching can achieve excellent results and reach a level of finesse that traditional processes are difficult to achieve.

Packaging and Printing Industry: It is used to etch brand logos, product information, anti-counterfeiting codes, etc. on product packaging. The information etched by lasers is clear, durable, and not easy to wear or fade, effectively improving the quality and safety of product packaging and also adding points to the shaping of the brand image.

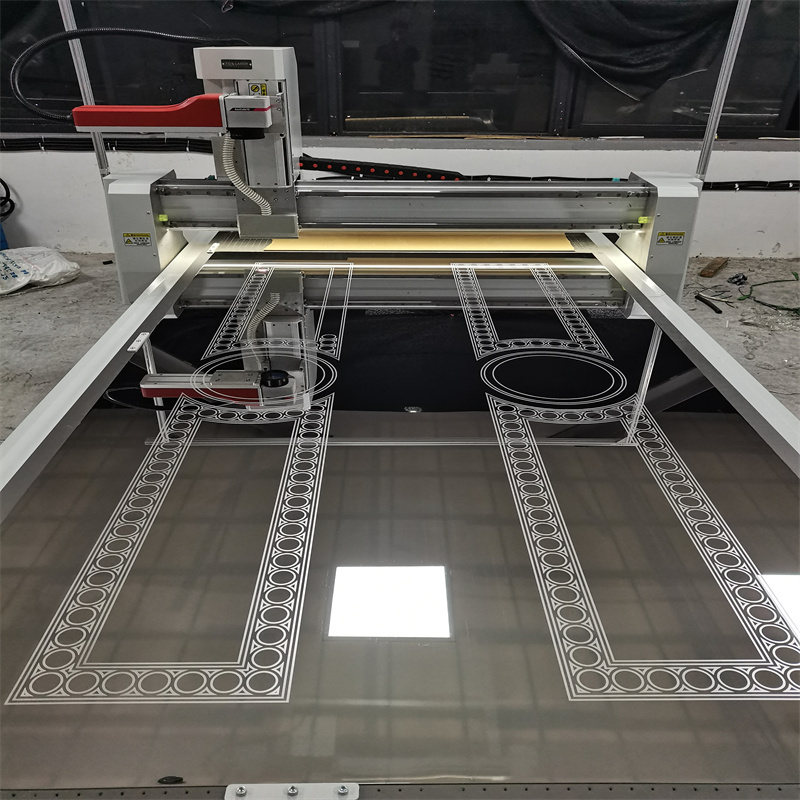

Artwork Production: Artists and craftsmen can use laser etching machines to create unique artworks on various materials such as wood, glass, and ceramics. From exquisite decorative ornaments to personalized souvenirs, laser etching brings unlimited creative space to artwork production, turning ordinary materials into unique artworks.

III. Advantages of Laser Etching Machines

High Precision: The laser beam can be focused into an extremely small spot, enabling etching with micron – level or even higher precision, ensuring the clarity and fineness of processed patterns and texts, and meeting the requirements of industries with extremely high precision requirements.

Non – contact Processing: During the laser etching process, there is no direct contact between the laser beam and the material surface, avoiding problems such as material deformation and scratching caused by tool wear and contact pressure in traditional mechanical processing. It is especially suitable for processing fragile materials.

Strong Flexibility: By controlling the path and energy of the laser beam through a computer, it is easy to achieve etching of various complex patterns and shapes. Just design the pattern in the computer software, and the laser etching machine can accurately carve it on the material without the need to make complex molds, greatly shortening the production cycle and reducing costs.

Environmentally Friendly and Energy – Saving: The laser etching process does not require the use of chemical reagents and does not produce pollutants such as wastewater and waste gas, meeting environmental protection requirements. At the same time, the energy consumption of laser etching machines is relatively low. While improving production efficiency, it also reduces energy consumption.

IV. Development Trends of Laser Etching Machines

With the continuous progress of science and technology, laser etching machines are also constantly developing and innovating. In the future, laser etching machines will develop towards higher precision, higher speed, and greater power to meet the growing market demand. At the same time, the integration with other advanced technologies such as artificial intelligence and automatic control will further enhance the intelligent level of laser etching machines, achieving more efficient and convenient production operations. In addition, special laser etching machines for different materials and application scenarios will continue to emerge, providing more professional and personalized solutions for various industries.

As an important tool for modern precision machining, laser etching machines are changing our production and lives with their unique advantages and broad application prospects. Whether in high – end manufacturing or in the field of creative design, it shows great potential. I believe that in the future, with the continuous improvement and innovation of technology, laser etching machines will bring us more surprises and possibilities.