As an important member of the laser cutting family, the CO₂ laser cutting machine, with its unique performance and wide applicability, holds an irreplaceable position in the fields of metal and non-metal processing, continuously driving production transformations across various industries.

- Technical core: The working mystery of CO₂ laser cutting

The working principle of a CO₂ laser cutting machine is based on gas laser excitation and energy conversion. Inside the device, under the action of a high – voltage electric field, the CO₂ gas reaches a state of population inversion, generating stimulated radiation and outputting infrared laser with a wavelength of 10.6 micrometers. This laser beam is focused onto the surface of the material through an optical system composed of mirrors and lenses. The high energy released instantaneously causes the material to rapidly melt and vaporize. With the high – pressure purging of auxiliary gases (such as oxygen and nitrogen), the molten slag is expelled from the cutting path, thus completing the cutting process.

Compared with other laser cutting technologies, the CO₂ laser cutting machine has the advantages of a simple gas laser structure and low maintenance costs. It can also generate relatively high laser power. With a power range from kilowatts to tens of thousands of watts, it can meet the requirements of both fine cutting of thin sheets and rapid blanking of thick plates, demonstrating strong adaptability in industrial production.

- Performance Advantages: Breaking Through Traditional Cutting Limitations in Multiple Dimensions

1. High – precision and High – quality Cutting

The spot diameter of the CO₂ laser cutting machine can be controlled between 0.1 – 0.3 millimeters. Combined with a precise servo control system, it can achieve a cutting accuracy of ±0.05 millimeters. Whether cutting complex gear profiles or engraving delicate circuit board wiring, the cutting edges can remain smooth and flat, with almost no burrs. This significantly reduces subsequent processing steps such as grinding and polishing, and notably improves product quality.

2. Efficient Production, Cost Reduction and Efficiency Improvement

Compared with traditional mechanical cutting methods (such as plasma cutting and water jet cutting), the cutting speed of the CO₂ laser cutting machine is increased by 3 – 5 times. For example, when cutting a 5 – millimeter – thick acrylic plate, the CO₂ laser cutting machine can complete a cutting length of 10 – 15 meters per minute. Moreover, there is no need to change the cutting tool, avoiding the downtime for adjustment due to tool wear. This effectively improves the equipment utilization rate and production efficiency, and reduces the production cost per unit product.

3. Wide Material Adaptability

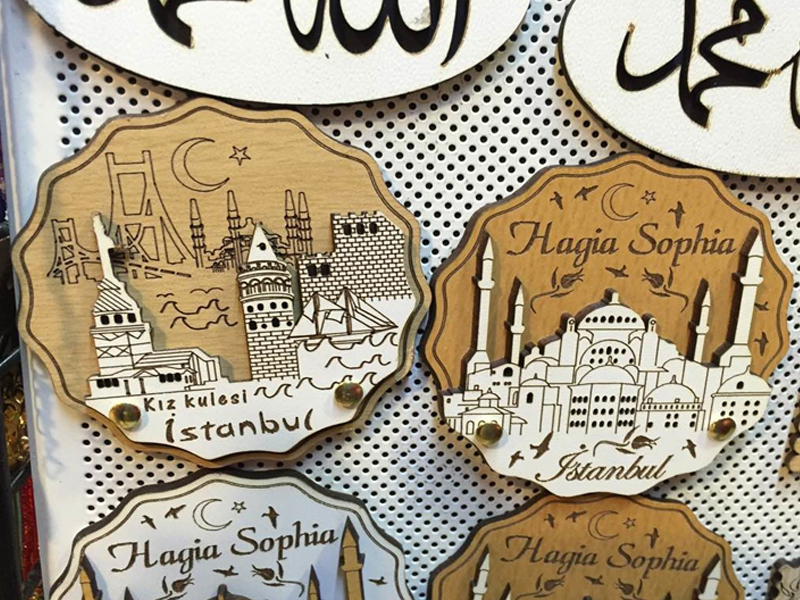

The “versatility” of the CO₂ laser cutting machine is reflected in its wide compatibility with various materials. In the field of non – metal materials, it can perfectly cut acrylic, leather, wood, cloth, etc., and is commonly used in advertising sign production, garment cutting, and furniture carving. In terms of metal materials, it can efficiently process stainless steel, carbon steel, aluminum alloy, etc., playing a key role in the automotive parts manufacturing and sheet metal processing industries. This “multi – purpose in one machine” feature greatly expands the application scenarios of the equipment.

- Industry Applications: Empowering Innovative Development in Multiple Fields

1.Advertising and Signage Industry: A Catalyst for Transforming Creativity into Reality

In the production of advertising signs, the CO₂ laser cutting machine translates designers’ creative ideas into tangible products. It can cut acrylic illuminated letters and metal hollow signs into any shape, and can even engrave delicate textures and patterns on leather and wood. Its high-precision cutting ensures that the edges of the fonts are clear and sharp, and the details of the patterns are vivid and lifelike, bringing more visually impactful products to the advertising industry and helping to enhance brand images.

2.Garment and Leather Industry: A Powerful Tool for Flexible Production

The garment customization and leather processing industries strive to strike a balance between personalization and efficient production. Through digital layout and automatic cutting, the CO₂ laser cutting machine can quickly handle complex orders for garment cutting pieces and leather carving. It not only avoids the problems of frayed edges of fabrics and deformed leather caused by traditional knife cutting, but also enables flexible switching between mass production and single-piece customization, meeting the diverse needs of the market.

3.Metal Processing Industry: A Guarantee for Precision Manufacturing

In fields such as automobile manufacturing and electrical equipment production, the CO₂ laser cutting machine is used to cut metal parts such as automobile body sheet metal parts and the casings of power distribution cabinets. Its laser beam with high energy density can complete the cutting of thick plates and the processing of small holes without causing thermal deformation, ensuring the dimensional accuracy and assembly quality of the components, and providing reliable technical support for high-end manufacturing industries.

- Development Trends: Advancing Hand in Hand towards Intelligence and Greenness

With the advancement of Industry 4.0 and intelligent manufacturing, CO₂ laser cutting machines are being upgraded in the direction of intelligence. Devices integrated with AI algorithms can automatically adjust the laser power and cutting speed according to the thickness and material of the workpiece, achieving the optimal matching of parameters. Internet of Things (IoT) technology endows the equipment with functions of remote monitoring and fault early warning, which facilitates enterprises to carry out intelligent production management. At the same time, in response to environmental protection requirements, the new generation of CO₂ laser cutting machines reduces the impact on the environment by optimizing the gas circulation system and reducing energy consumption, moving towards the goal of green manufacturing.

CO₂ laser cutting machines, with their technical advantages and extensive applications, have become key equipment in the field of industrial manufacturing. In the future, they will continue to break boundaries through technological innovation, inject new impetus into the high-quality development of various industries, and drive the global manufacturing industry to a higher level.