In today’s era of rapid technological development, laser technology has become one of the core forces driving industrial transformation. Among them, the laser marking machine, with its unique technological advantages, shines brightly in numerous fields such as manufacturing, electronics, healthcare, and packaging, endowing products with unique markings and value.

- I. The Working Principle of the Laser Marking Machine: Precise Collaboration between Light and Heat

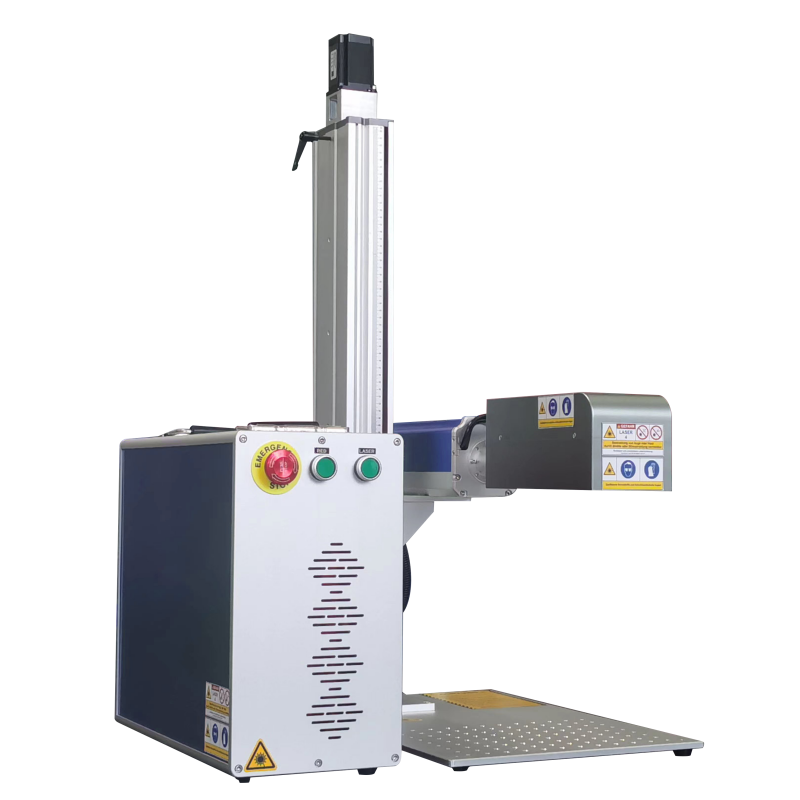

The working principle of the laser marking machine is based on the characteristic of high energy density of the laser. It generates a high-frequency and high-energy laser beam through a laser device, and the laser beam is precisely focused on the surface of the object to be processed through an optical focusing system.

For metallic materials, the laser energy will cause the surface material to heat up rapidly, melt, and even vaporize, thus forming a permanent mark. For non-metallic materials such as plastics and leathers, the laser will trigger reactions like discoloration and carbonization of the materials, achieving a clear marking effect.

The control system of the laser marking machine is like its “brain”. It can precisely control the movement trajectory, energy level, and action time of the laser beam. Through the programming of computer software, operators can easily design various complex marking contents such as patterns, texts, and barcodes, enabling the laser marking machine to meet the personalized marking requirements of different customers and different products.

- II. Extensive Application Areas: Injecting New Vitality into Various Industries

- In the manufacturing industry, laser marking machines are extremely widely applied. In automobile manufacturing, they are used to apply permanent markings on key components such as engine parts and vehicle body frames. These markings not only contain information such as product models, production dates, and batch numbers but also serve as an important basis for product quality traceability. At the same time, laser marking also plays an important role in the personalized decoration of automobile interior parts. For example, unique patterns and brand logos are engraved on components such as steering wheels and instrument panels, enhancing the aesthetic appeal of the products and brand recognition.

The electronics industry has extremely high requirements for the refinement and miniaturization of products, and laser marking machines precisely meet this need. On electronic products such as integrated circuits, chips, and mobile phone casings, laser marking can achieve high-precision markings at the micron level, clearly indicating product models, parameters, production serial numbers, and other information, and the markings will not cause any damage to the performance or appearance of the products. In addition, the permanent nature of laser marking can effectively prevent the counterfeiting of electronic products, safeguarding the interests of enterprises and consumers.

The medical industry has strict requirements for the safety and reliability of equipment and instruments, and laser marking machines also play an important role in this field. On products such as syringes, scalpels, and implantable medical devices, laser marking can create clear and permanent markings, including product specifications, usage instructions, production dates, batch numbers, and other information, making it convenient for medical staff to identify and trace, ensuring the safe use of medical products. Meanwhile, laser marking technology can also be used to produce anti-counterfeiting markings on pharmaceutical packaging, effectively combating the counterfeiting of drugs.

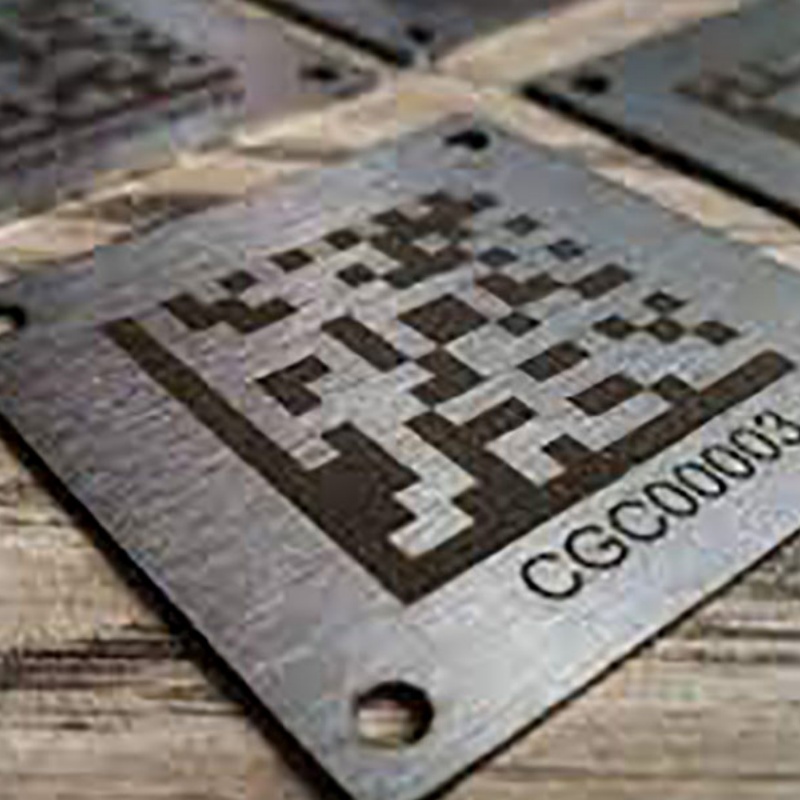

In the packaging industry, laser marking machines add a unique charm to product packaging. They can engrave exquisite patterns, texts, and barcodes on the packaging of products such as food, beverages, and cosmetics. This not only improves the packaging grade and visual effect of the products but also enables anti-counterfeiting and traceability functions of the products. For example, the anti-counterfeiting markings made by laser marking on wine packaging are difficult to replicate. Consumers can query the authenticity of the products and related information by scanning the codes, enhancing consumers’ trust in the products.

- III. Remarkable Technological Advantages: Leading the Development Trend of the Industry

Compared with traditional marking methods, laser marking machines have unparalleled advantages. Firstly, they possess extremely high precision and can achieve markings at the micron or even nanometer level, which is beyond the reach of traditional marking methods. Whether it is marking fine circuit diagrams or tiny text identifiers, laser marking machines can handle them with ease, ensuring that the markings are clear, accurate, and aesthetically pleasing.

Secondly, laser marking machines are highly efficient. They can complete the marking work of a large number of products in a very short time, greatly improving production efficiency. At the same time, the non-contact processing method of laser marking will not generate any mechanical stress or abrasion on the surface of the product, avoiding problems such as product deformation and damage that may be caused by traditional marking methods, and ensuring the quality and integrity of the products.

In addition, laser marking machines also have strong flexibility and adaptability. They can mark on the surfaces of objects with various different materials, shapes, and sizes. Whether it is a flat surface, a curved surface, or a complex three-dimensional structure, an ideal marking effect can be achieved. Moreover, through software programming, operators can change the marking content and patterns at any time to meet the personalized needs of different customers.

With its unique working principle, extensive application areas, remarkable technological advantages, and broad development prospects, the laser marking machine has become an indispensable and important piece of equipment in modern industrial production. It not only endows products with unique markings and value but also promotes the technological progress and industrial upgrading of various industries. In the future, the laser marking machine will continue to take innovation as the driving force, constantly explore new application areas, and make greater contributions to the development of the global manufacturing industry.