Laser tube cutting machines, with their outstanding performance, are rapidly becoming the preferred processing equipment in numerous industries, bringing revolutionary changes to the field of tube processing.

The core advantages of laser tube cutting machines lie in high precision, high efficiency, and high flexibility. Traditional tube cutting methods, such as mechanical cutting and flame cutting, often suffer from issues like low cutting precision, rough cut edges, and high material waste. In contrast, laser tube cutting machines focus a high – energy – density laser beam on the surface of the tube, instantly melting or vaporizing the material to achieve precise cutting. Their cutting precision can reach the millimeter or even micron level, meeting the stringent requirements of high – end industries such as aerospace and automotive manufacturing for tube processing. For example, in the production of automotive exhaust pipes, laser tube cutting machines can accurately control the shape and size of the cut, ensuring a perfect match between the exhaust pipe and the engine, thereby enhancing the overall performance of the vehicle.

In terms of efficiency, laser tube cutting machines demonstrate strong competitiveness. They adopt an automated control system that can quickly read design drawings and automatically adjust cutting parameters. Compared with traditional cutting equipment, laser tube cutting machines can increase the cutting speed severalfold and do not require frequent tool changes, significantly reducing downtime. In large – scale tube processing projects, their high – efficiency processing capabilities can notably shorten the production cycle, helping enterprises respond quickly to market demands. For instance, in the processing of steel – structure tubes in the construction industry, laser tube cutting machines can complete the cutting of a large number of tubes with complex shapes in a short time, providing strong support for the smooth progress of construction projects.

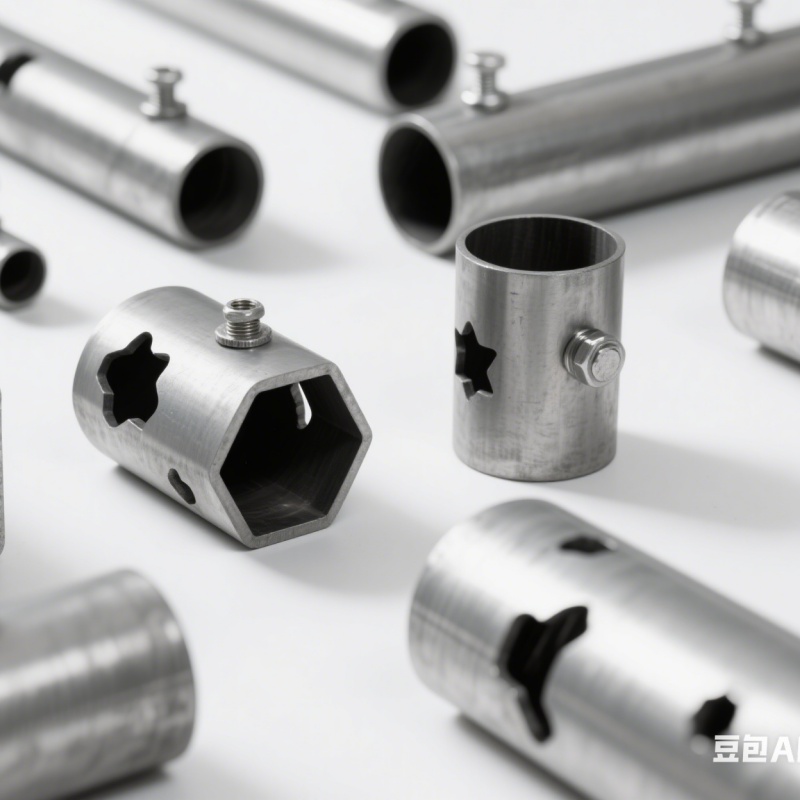

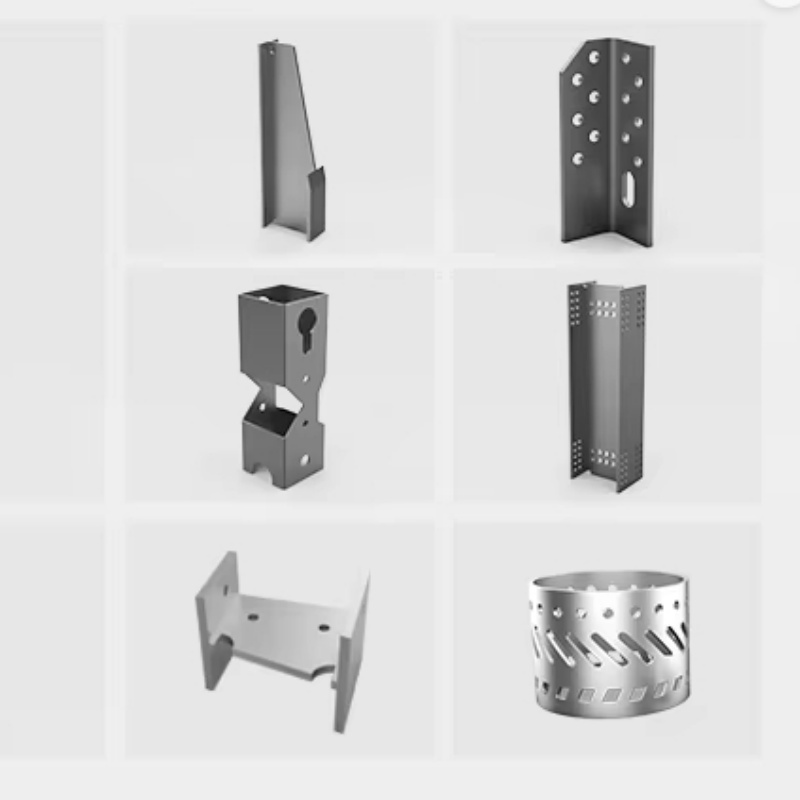

The flexibility of laser tube cutting machines is also remarkable. They can accommodate various types of tubes, including round tubes, square tubes, rectangular tubes, and special – shaped tubes. They can also perform cutting of various complex patterns and texts. Whether it is simple straight – line cutting or elaborate hollow carving, laser tube cutting machines can handle it with ease. In the advertising production industry, laser tube cutting machines can cut metal tubes into various creative shapes, adding a unique artistic charm to billboards.

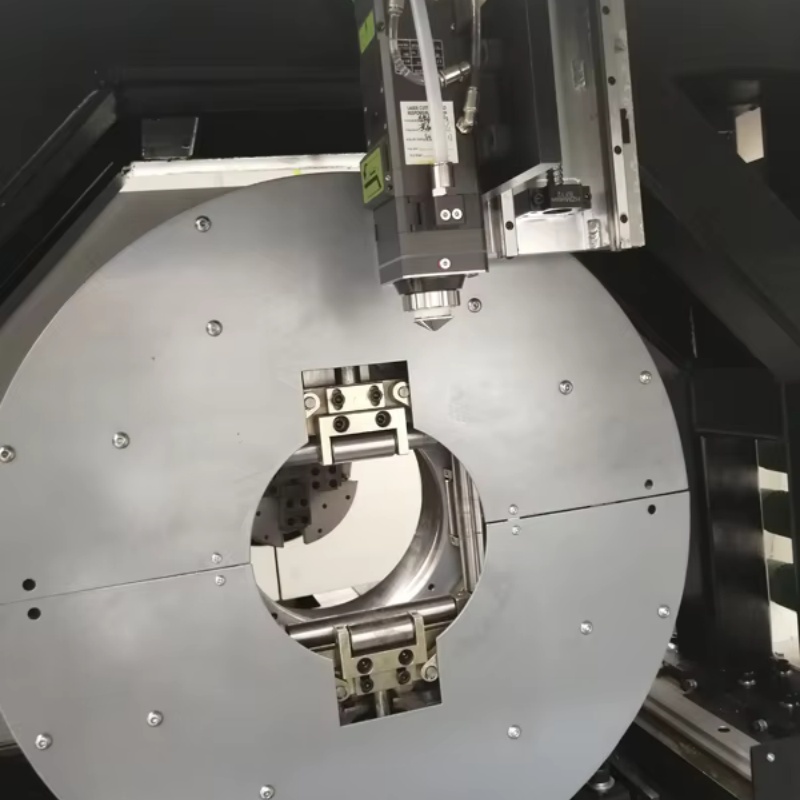

From a technical principle perspective, laser tube cutting machines mainly consist of components such as a laser generator, a numerical control system, a cutting head, and a transmission device. The laser generator produces a high – energy laser beam, which is transmitted to the cutting head through an optical fiber. The numerical control system precisely controls the movement trajectory of the cutting head and the output power of the laser according to design requirements. The transmission device ensures the stable conveying of the tube during the cutting process. All components work in concert to achieve efficient and precise cutting operations.

With the continuous advancement of technology, laser tube cutting machines are evolving towards intelligence and integration. Some new – generation devices are equipped with intelligent vision systems that can automatically identify the size and position of tubes, further improving cutting precision and efficiency. Meanwhile, through integration with the industrial Internet, laser tube cutting machines can enable remote monitoring and data management, facilitating enterprises to optimize and adjust the production process in real – time.

Laser tube cutting machines, with their unparalleled advantages, have become an important force in promoting the upgrading of the manufacturing industry. They not only enhance the quality and efficiency of tube processing but also open up new possibilities for the innovative development of various industries. In the future, with continuous technological breakthroughs, laser tube cutting machines are bound to play an even greater role in a broader range of fields and lead the tube processing industry to new heights.