In the realm of metal decoration, laser etching machines have emerged as indispensable tools for translating creative designs into tangible artistry. However, with a plethora of models available in the market, each featuring distinct specifications, choosing the right machine requires a comprehensive understanding of key factors.

I. Core Performance: The Choice of Laser Type and Power

The type of laser and power output are fundamental determinants of etching performance. Fiber lasers, with a wavelength of 1.06 micrometers, are the top choice for metal etching. They can effectively process common metals such as stainless steel, aluminum, and brass, delivering high – precision and deep engraving while minimizing the heat – affected zone. MOPA lasers, an advanced variant of fiber lasers, offer adjustable pulse widths, making them particularly adept at creating intricate patterns with superior contrast and sharp edges. On the other hand, CO2 lasers, primarily designed for non – metallic materials, demand additional treatments like coating applications when used on metals, resulting in lower efficiency and subpar results. Diode lasers, with their limited power, are only suitable for light – marking tasks and fall short for detailed metal decoration work. In terms of power, 10W – 20W lasers are sufficient for shallow surface marking, ideal for simple decorative elements. Medium – powered 20W – 30W fiber lasers strike a balance between speed and depth, catering to daily metal decoration needs. High – power lasers above 50W are essential for large – scale, deep etching on metal sheets.

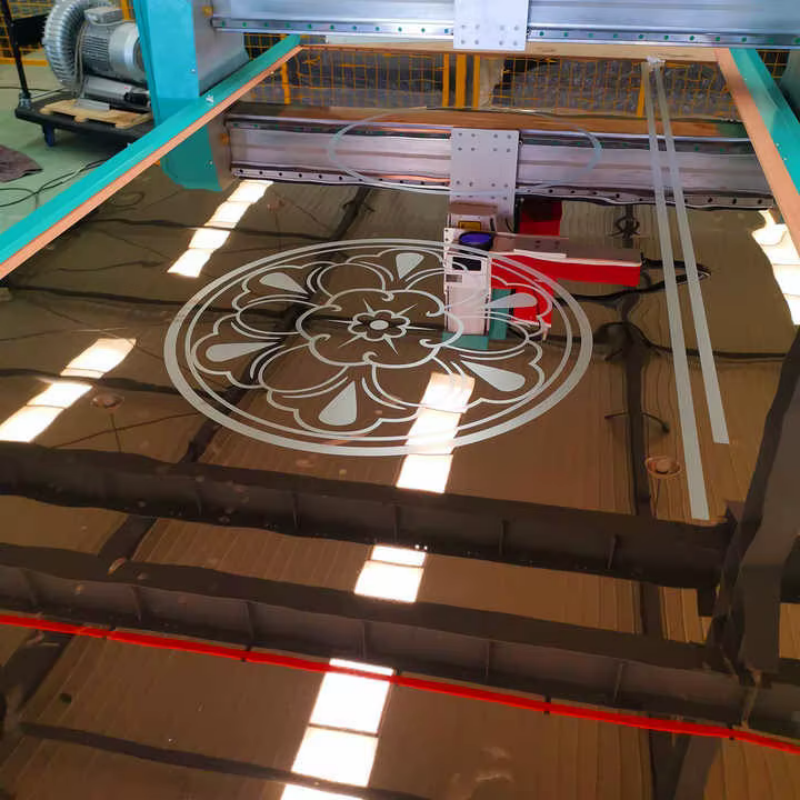

II. Detail Control: Precision, Speed, and Material Compatibility

Precision, speed, and material compatibility are crucial for both quality and versatility. A precision level of 0.01mm is necessary to ensure sharp and detailed patterns, which is a must in the metal decoration industry. While etching speed is vital for mass production, it should not compromise precision. Finding the right equilibrium between the two can significantly enhance productivity. Moreover, as metal decoration often involves multi – material processing, selecting a machine compatible with both metals and non – metals like plastics and wood can expand business opportunities.

III. Operation Guarantee: Cooling System and Software Support

The cooling system and software support play vital roles in equipment operation and user experience. Air – cooled systems, characterized by their low cost and easy maintenance, are suitable for low – power devices with short working hours. In contrast, water – cooled systems provide efficient and stable cooling, enabling high – power machines to operate continuously for extended periods, making them perfect for large – scale production. Software compatibility with design tools like AutoCAD is essential. Additionally, professional laser engraving software such as EasyCAD and LightBurn, equipped with powerful graphic editing and path – optimization functions, facilitates the seamless transformation of designs into etched patterns.

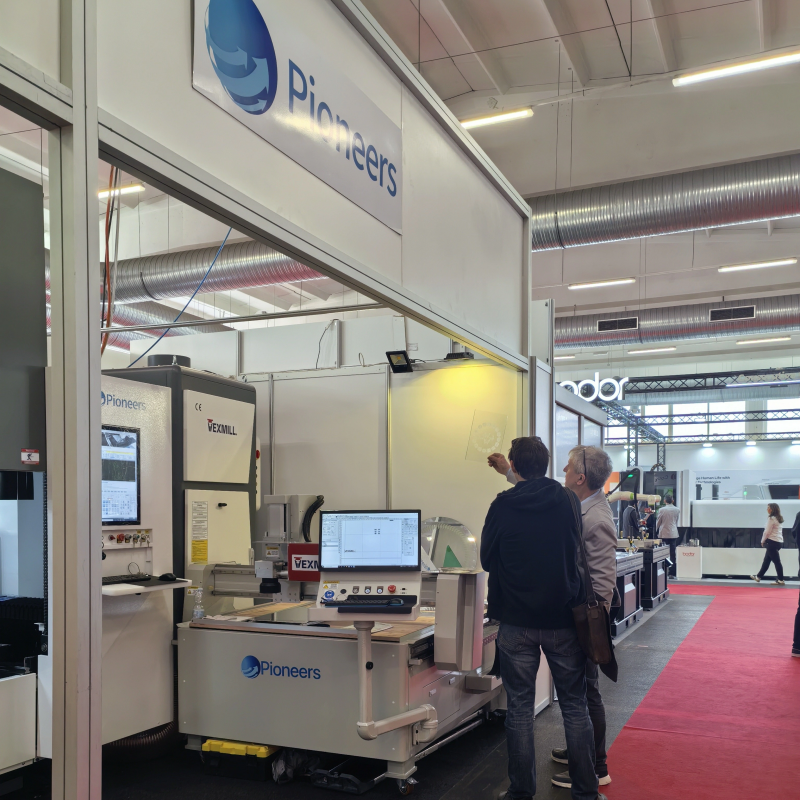

IV. Other Considerations: Working Area, Manufacturing Quality, and After-sales Service

Other key considerations include the working area, manufacturing quality, price, and after – sales service. The working area must accommodate the size of processed metal pieces; larger decorative items require machines with expansive workbenches and long – stroke laser heads. Manufacturing quality directly impacts equipment stability and lifespan, and researching component brands and user reviews can help gauge this. While cost – effectiveness is important, it should not overshadow quality. A reliable after – sales service, covering installation, maintenance, and technical support, ensures uninterrupted operation.

In conclusion, selecting an appropriate laser etching machine for metal decoration demands a holistic assessment of these factors. By aligning machine capabilities with specific production requirements, businesses can acquire a tool that not only meets current needs but also supports future growth in the competitive metal decoration market.