The handheld laser welding machine is a portable application device of laser welding technology. It combines the high-precision advantages of traditional laser welding with the flexibility of handheld operation. It is especially suitable for small and medium-sized batch production, on-site maintenance, and welding of complex workpieces. The following is a detailed analysis of its core advantages:

- Portable and flexible, adaptable to multi-scenario operations

Strong mobility, breaking through site limitations

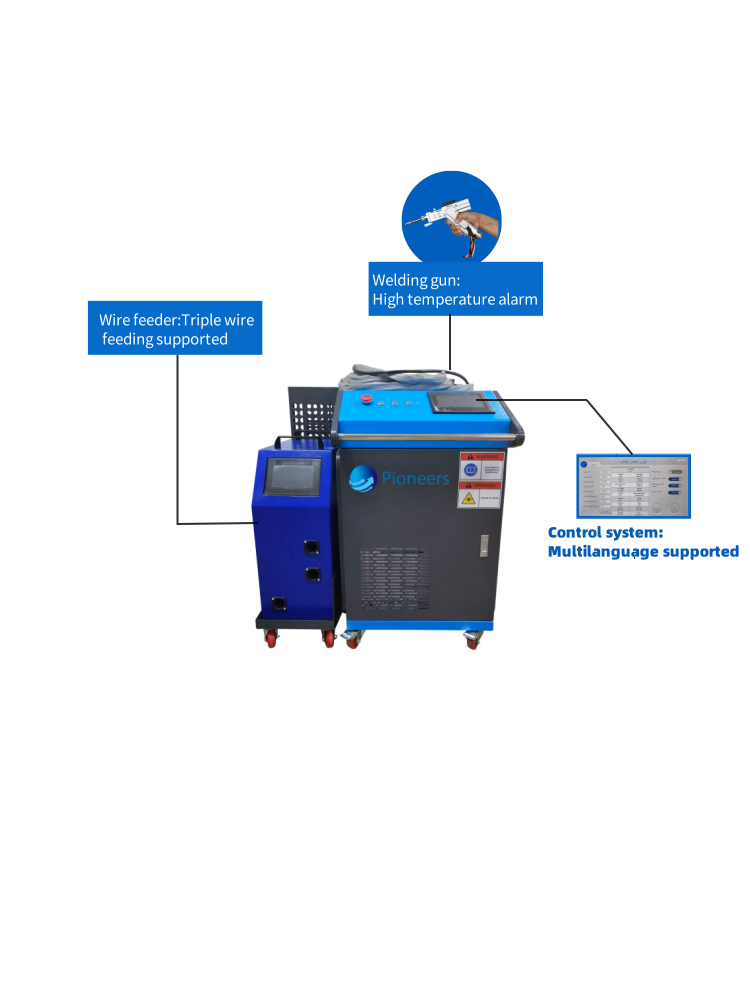

The equipment is small in size (host + handheld welding gun design), can be moved with rollers or portable brackets, and does not require a fixed workbench. It is suitable for on-site welding (such as steel structure installation, pipeline maintenance, outdoor equipment repair), welding of special-shaped parts (such as arcs, corners, irregular curved workpieces) and multi-station switching production.

Flexible operation to cope with complex structures

The handheld welding gun transmits laser energy through optical fiber, and the gun head can rotate 360° to penetrate into narrow spaces that are difficult for traditional equipment to reach (such as inside containers and gaps between multi-layer stacked parts), solving the problem of “dead corner” welding. - Lower the threshold and simplify the operation process

No professional welder is required, shortening the training cycle

Adopting intelligent control system (such as touch screen parameter adjustment), ordinary workers can get started after simple training (traditional arc welding requires long-term practical experience), reducing labor costs, especially suitable for rapid deployment of small and medium-sized enterprises.

One-click mode switching, adaptable to a variety of materials

Different welding modes (such as continuous welding, pulse welding, spot welding) can be preset, and welding parameters of stainless steel, aluminum alloy, carbon steel, copper and other materials can be switched with one click, compatible with thin plates (0.5mm) and medium and thick plates (3-5mm) welding. - Efficient welding, reducing post-processing costs

Fast welding speed, suitable for small and medium batch production

The welding speed can reach 0.5-2 meters/minute (depending on the thickness of the material), which is 3-5 times faster than traditional argon arc welding, especially suitable for batch welding of flanges, angle irons, flat plate splicing and other standard parts.

High weld quality, reducing secondary processing

The laser energy is concentrated, the heat-affected zone is only 0.1-0.3mm, the welding deformation is small, the weld is smooth and flat, no or only simple grinding is required (traditional welding often requires a lot of polishing), saving more than 50% of post-processing time. - Safe and environmentally friendly, lower energy consumption

Non-contact welding, reducing the risk of work-related injuries

No need to touch the workpiece, avoiding problems such as electrode adhesion and wire spatter in traditional welding; with protective glasses, laser radiation can be isolated, and the operation safety is higher than arc welding (no risk of electric shock).

Low energy consumption + less pollution

The energy consumption is only 1/3-1/2 of that of traditional welding equipment (such as a 2000W handheld laser welder consumes about 2 degrees of electricity per hour), and there is no welding slag or exhaust gas emissions (some processes require auxiliary gas, with low consumption), which meets environmental protection requirements. - Integrated design, low maintenance cost

Modular structure, convenient troubleshooting

Adopting the modular design of fiber laser + intelligent control system, the life of core components (such as laser, optical fiber) can reach more than 100,000 hours. Daily maintenance only requires cleaning the lens and checking the optical fiber interface. The maintenance cost is 40% lower than that of traditional welding equipment.

Adaptive automation upgrade

Some high-end handheld welders can be connected to robot arms and quickly switched to automated welding systems, taking into account flexible production and scale requirements. - Typical application scenarios

Sheet metal processing: corner welding and lap welding of chassis cabinets, shelves, door and window frames.

Hardware products: bathroom accessories (faucets, showers), furniture hardware (table and chair brackets), and decorative parts welding.

Mechanical maintenance: mold repair, on-site repair of equipment parts (such as gear and guide rail crack welding).

New energy industry: lithium battery shell sealing welding, photovoltaic bracket welding.

Stainless steel products: kitchen equipment (sinks, range hoods), precision welding of medical device shells.

Summary

Handheld laser welding machines, with their triple advantages of “portability + high precision + easy operation”, fill the gap between traditional laser welding (fixed tooling required) and manual welding (low precision and slow efficiency), and are especially suitable for small and medium-sized enterprises, customized processing scenarios and mobile welding needs. With the iteration of technology (such as lightweight design and intelligent parameter optimization), its application scope is extending from thin plates to medium and thick plates, and from metals to non-metallic materials, becoming an important tool for improving efficiency in modern manufacturing.