CO2 laser cutting machine is a laser processing equipment that uses CO2 gas as the activation medium, and occupies an important position in the field of modern industrial production and manufacturing. Its core principle is based on gas discharge excitation technology. In a closed laser generator, CO2, nitrogen, helium and other gases mixed in a specific proportion are ionized under the action of a high-voltage electric field to form a gas discharge plasma. In this process, electrons collide with gas molecules frequently, causing the CO2 molecules to gain energy and transition to a high-energy state. When these molecules transition from a high energy level to a low energy level, they will release an infrared laser with a wavelength of 10.6 microns. After being focused by the optical system, this laser becomes the key energy source for cutting materials.

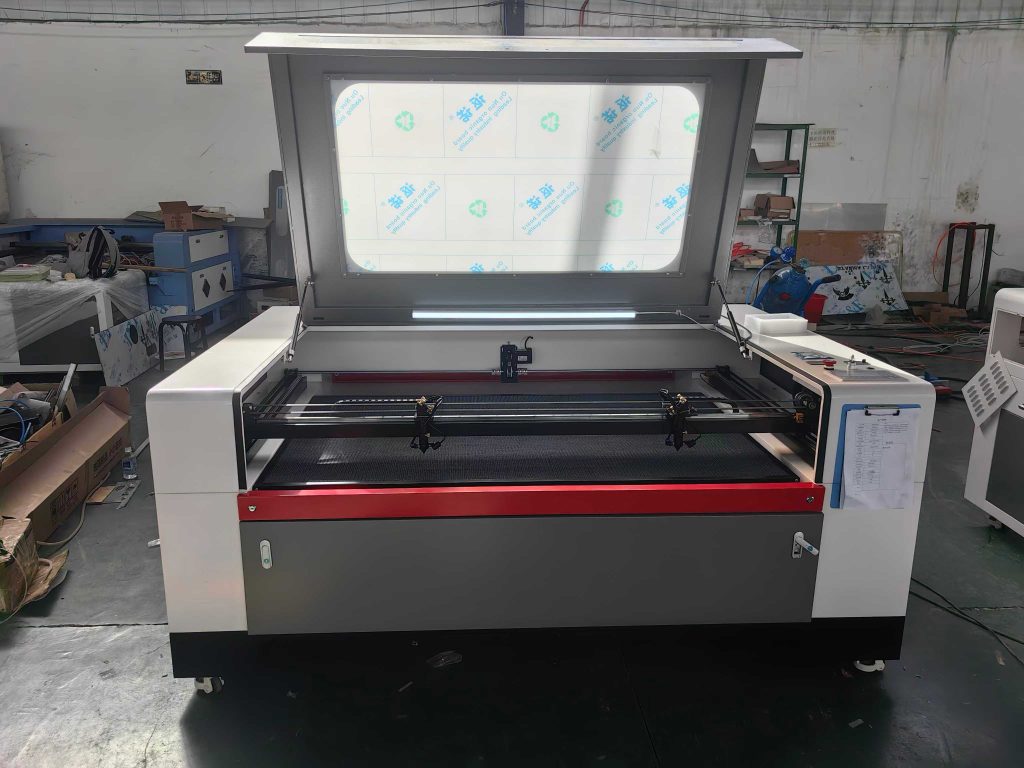

From the perspective of equipment composition, the CO2 laser cutting machine is mainly composed of a laser generator, an optical focusing system, a CNC motion system, a work surface and an auxiliary gas system. As the core component, the laser generator directly determines the power and stability of the laser; the optical focusing system can accurately focus the laser beam on the surface of the material, forming a very small spot and increasing the energy density; the CNC motion system is controlled by a computer program to achieve precise movement of the cutting head in the X and Y axis directions; the worktable is used to carry the material to be processed; the auxiliary gas system sprays high-pressure gas during cutting to help blow away the melted and vaporized material residues, while protecting the focusing lens from being contaminated by splashes.

The carbon dioxide laser cutting machine has many significant advantages. In terms of cutting accuracy, it can achieve high-precision cutting of ±0.05 mm, which can meet various fine processing needs; the cutting speed is fast, and the efficiency is several times higher than that of traditional mechanical cutting methods. For example, the cutting speed of acrylic sheets with a thickness of 1 mm can reach several meters per minute; its non-contact processing characteristics avoid mechanical extrusion and deformation of the material, and are particularly suitable for the processing of thin materials and easily deformed materials; in addition, the equipment also supports the cutting of complex graphics, and various personalized designs can be easily realized through computer programming, which greatly expands the flexibility and diversity of processing.

In the application field, CO2 laser cutting machines perform very well. In the advertising and logo industry, it is often used to cut materials such as acrylic and PVC boards to make various exquisite luminous characters and signboards; in the clothing and leather industry, it can achieve rapid cutting of fabrics and leather, and the cutting edges are smooth without burrs; in the field of handicraft processing, it can engrave complex patterns on materials such as wood, bamboo, and glass, giving the products unique artistic value; in the electronics and electrical industry, it can be used to cut precision parts such as flexible circuit boards and membrane switches.

Despite its superior performance, the daily maintenance of CO2 laser cutting machines cannot be ignored. Clean the optical lens regularly to ensure the efficiency of laser transmission; check the gas pressure and ratio in the laser generator and replenish the gas in time; maintain the CNC system to ensure the accuracy of the cutting path; clean the auxiliary gas system to prevent gas blockage. Only by doing these maintenance work well can we ensure the long-term stable operation of the equipment and maintain good cutting results.

With the continuous advancement of technology, CO2 laser cutting machines are moving towards higher power, higher precision, intelligence and automation. In the future, it will play an important role in more emerging fields and continue to inject new impetus into the high-quality development of the manufacturing industry.