Smart mirrors, as a crucial component of smart homes, are gradually becoming part of people’s lives. Their production processes are constantly evolving, and the emergence of smart mirror glass laser sandblasting machines has brought both efficiency and precision improvements to smart mirror manufacturing.

Traditional glass processing technologies, such as mechanical drilling and chemical etching, often fall short when it comes to meeting the demands of smart mirror manufacturing. Mechanical drilling is inefficient and prone to cracks and flaws on the glass surface; chemical etching suffers from low processing precision and burrs, and the use of chemical reagents can also pollute the environment. The advent of smart mirror glass laser sandblasting machines has perfectly addressed these challenges.

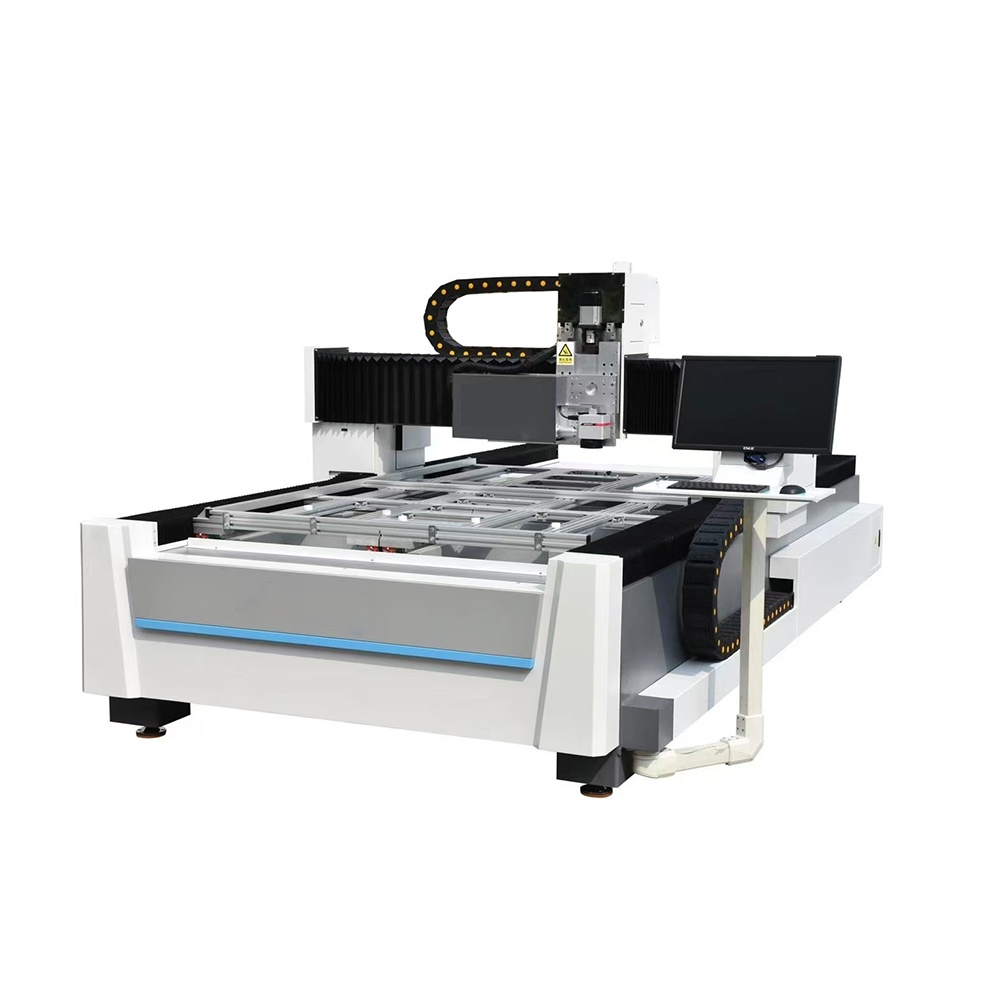

Smart mirror glass laser sandblasting machines utilize high-energy laser beams to precisely process the glass surface. During the sandblasting process, precise control of the laser beam’s energy and focus creates a uniform, finely grained frosted finish. Laser sandblasting offers unparalleled advantages over traditional sandblasting. First, it offers exceptionally high precision. Laser beams can be focused down to the micron level, enabling precise control of the sandblasting area and depth. This is particularly important for manufacturing smart mirrors with complex patterns and fine textures. Secondly, efficiency is significantly improved. Laser processing speed allows for the sandblasting of large areas in a short period of time, significantly shortening production cycles. For example, in actual production, laser sandblasting machines can complete sandblasting of common smart mirror glass sizes in just minutes, while traditional sandblasting processes can take tens of minutes or even longer.

Smart mirror glass laser sandblasting machines also excel in drilling holes. They can drill holes in glass in seconds with extremely high precision, and the hole size can be precisely controlled to meet specific requirements. This makes the installation of various electronic components in smart mirrors more convenient and precise, effectively improving product quality and stability. Furthermore, laser drilling eliminates the burrs and joint marks common with traditional mechanical drilling. The resulting glass surface is smooth and flat, eliminating the need for additional grinding and polishing. This not only saves time and costs, but also improves the product’s appearance.

Smart mirror glass laser sandblasting machines have a wide range of applications. In addition to smart mirror manufacturing, laser sandblasting machines are also used in applications requiring high-precision glass processing, such as automotive glass, architectural decorative glass, and medical equipment glass. Its flexibility and adaptability enable it to easily handle a variety of complex processing requirements. For example, in architectural decoration, laser sandblasting machines can create exquisite patterns and designs on glass, adding a unique artistic charm to the building. In medical equipment, they can perform high-precision drilling and sandblasting on glass, meeting the special requirements of medical equipment glass components.

From an environmental perspective, laser sandblasting machines for smart mirrors also offer significant advantages. Compared to traditional chemical etching processes, laser processing does not use harmful chemicals and does not produce pollutants such as wastewater and exhaust gas, meeting today’s demand for green manufacturing. Furthermore, the high efficiency of laser processing means energy savings, reducing production costs for enterprises, and achieving a win-win situation in both economic and environmental benefits.

With the continuous advancement of technology, the performance of laser sandblasting machines for smart mirrors is also being continuously optimized and improved. In the future, it will play a more important role in smart mirror manufacturing and the entire glass processing industry, driving the industry towards higher precision, higher efficiency, and greater environmental protection, bringing more high-quality glass products to people.

It can be foreseen that the smart mirror glass laser sandblasting machine will play a more important role in smart mirror manufacturing and the entire glass processing industry, promoting the industry to develop in the direction of higher precision, higher efficiency and more environmental protection, bringing more high-quality glass products to people and enriching people’s life experience.