In fields such as microelectronics manufacturing, new energy batteries, and cultural and creative customization, laser etching machines are rapidly gaining popularity due to their non-contact, high-precision, and low-pollution advantages. Requiring no chemical reagents or electrical current, laser etching machines rely solely on a high-energy laser beam to “carve” micron- or even nanometer-scale patterns onto material surfaces, revolutionizing the processing logic of traditional etching techniques. Compared to the previously widely used chemical and electrolytic etching methods, laser etching machines differ significantly in their principles, performance, and applicable scenarios. This article will delve into the workings of laser etching machines and compare the three etching technologies from key perspectives, revealing their technical advantages and application boundaries.

- 1.Laser Etching Machines: Precise Removal Through “Light Energy Conversion”

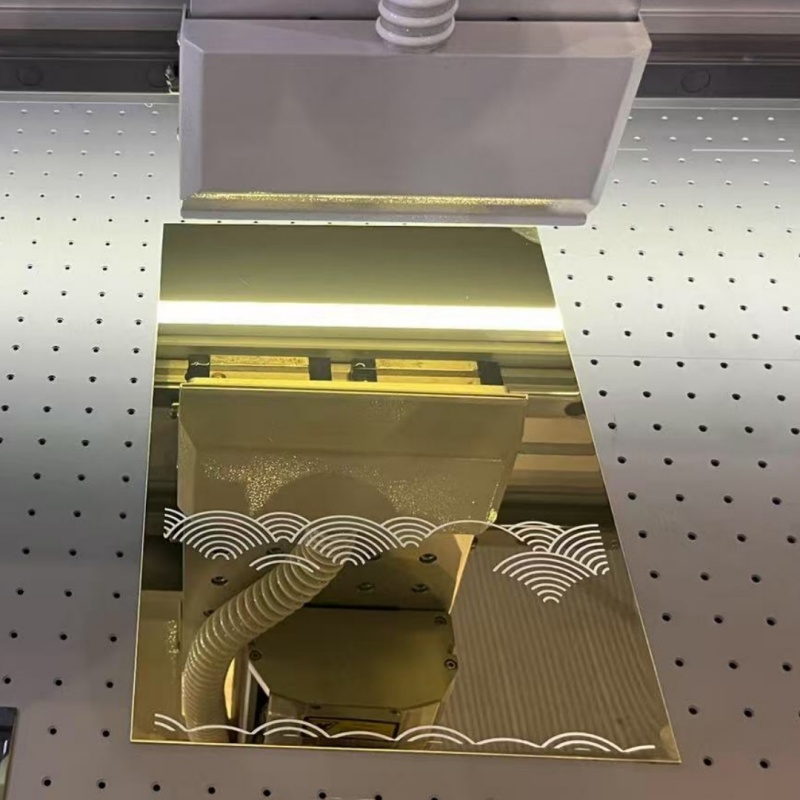

The core principle of laser etching is the targeted conversion of light energy and the selective removal of materials. By focusing a high-energy-density laser beam on the surface of a material, the laser utilizes photothermal, photochemical, or photophysical effects to instantly vaporize, melt, or decompose the target area, thereby achieving pattern processing. The entire process requires no contact with the workpiece and no additional etching medium. High-precision etching is achieved simply by computer-controlled laser beam path and energy.

Depending on the material being processed, laser etching relies on two key effects: For inorganic materials like metals and ceramics, the laser beam’s energy is rapidly converted into heat (the photothermal effect), raising the material’s surface temperature to thousands of degrees Celsius within microseconds. The metal in the target area instantly vaporizes or melts, creating etched grooves. For organic materials like plastics, wood, and PCB substrates, the laser energy directly breaks down the material’s molecular bonds (the photochemical effect), causing the organic molecules to decompose into small gases (such as CO₂ and H₂O) and escape, preventing molten residue from affecting pattern accuracy.

Common laser types are also adapted to the material’s characteristics: Fiber lasers (1064nm wavelength, with concentrated energy and strong penetration) are commonly used for metal processing; CO₂ lasers (10.6μm wavelength, easily absorbed by organic materials) are commonly used for non-metal processing; and ultraviolet lasers (266nm wavelength, capable of etching with nanometer-level precision) are used for processing ultra-precision devices like semiconductor chips. During the entire etching process, laser power (10-100W), scanning speed (100-1000mm/s), and spot diameter (5-50μm) are the key parameters controlling the etching effect. The higher the power and the slower the speed, the deeper the etching; the smaller the spot diameter, the clearer the pattern edge.

- 2. Core Differences Between the Three Major Etching Technologies: A Comprehensive Comparison from Principle to Application

The fundamental difference between laser etching and chemical and electrolytic etching lies in their energy source and material interaction. This directly determines significant differences in precision, environmental friendliness, and applicable scenarios. This comparison can be conducted along five core dimensions:

- 3. Reaction Mechanism: From “Chemical/Electrochemical” to “Physical/Photochemical”

Chemical etching relies on a redox reaction, dissolving the material through a spontaneous reaction between the etching solution (such as ferric chloride or hydrofluoric acid) and the metal. Electrolytic etching relies on anodic dissolution in an electrolytic cell, using an external current to drive metal ions away from the workpiece. Laser etching, on the other hand, does not rely on chemical or electrochemical reactions at all. Instead, it removes the material through the instantaneous action of laser energy (vaporization and decomposition). The entire process involves no chemical reaction and requires no conductive medium. 2. Precision Control: Laser Etching Achieves a “Nanoscale Breakthrough”

Chemical etching is affected by solution diffusion, resulting in a precision of 50-100μm and prone to “side etching” at the edges of the pattern. Electrolytic etching, through current control, can achieve a precision of 5-10μm, making it suitable for precision structure processing. Laser etching, with its tiny focused spot (down to under 1μm), can stably control precision to 0.1-1μm, even enabling nanoscale texture processing. This makes it particularly suitable for ultra-precision devices such as mobile phone camera modules and semiconductor chips. 3. Environmental Protection and Cost: Laser Etching: “High Initial Investment, Low Later Consumption”

Chemical etching requires the use of highly corrosive solutions, resulting in high costs for waste disposal and ongoing consumables due to regular replacement of the etching solution. While electrolytic etching does not produce highly corrosive waste, the electrolyte solution requires circulation and maintenance, and the cost of high-stability power supply equipment is relatively high. Laser etching, on the other hand, produces no chemical waste and consumes only electricity, resulting in extremely low ongoing maintenance costs. However, the initial equipment investment is significantly higher than the other two options (an industrial-grade laser etching machine is typically 3-5 times the price of a chemical etching machine). 4. Applicable Materials: Laser Etching: “Widest Coverage”

Chemical etching is primarily suitable for metals (copper, stainless steel, aluminum, etc.), but has poor etching effects on non-metallic materials. Electrolytic etching can only process conductive materials and cannot process insulating materials like plastic and glass. Laser etching overcomes the limitations of material conductivity and can process both metals (such as stainless steel and titanium alloys) and non-metals (such as ceramics, glass, and acrylic). It can even achieve high-precision etching on flexible materials (such as PI film), making it suitable for a wide range of applications, including electronics, automotive, and cultural and creative industries.

- 4. Processing Efficiency: Each has its own advantages and disadvantages; choose according to your needs.

Chemical etching is suitable for large-scale batch processing (such as etching a full plate of stainless steel signs). It can process multiple workpieces at a time, with an hourly production capacity of hundreds of pieces. Electrolytic etching requires connecting electrodes to each piece, making it slightly less efficient. While laser etching offers high precision, etching a single line requires scanning the laser beam point by point, resulting in lower processing efficiency for large areas. It is more suitable for small-batch, customized production of complex patterns (such as personalized metal jewelry and precision sensors).

- 5. Technology Selection: There’s No “Best,” Only “Most Suitable”

The three etching technologies are not mutually exclusive; instead, each has distinct application boundaries. For cost-effective processing of large-area metal decorative parts (such as decorative patterns on stainless steel doors and windows), chemical etching remains the most cost-effective option. For fabricating the delicate circuitry of semiconductor chips (such as the inner layers of PCBs), electrolytic etching offers advantages due to its high precision and stability. For ultra-precision, multi-material, or contactless processing requirements (such as etching the insulation layer of mobile phone fingerprint recognition modules and new energy battery tabs), laser etching is the only viable option.

With the continuous advancement of laser technology, today’s laser etching machines can now integrate AI vision positioning to achieve “fully automatic high-precision processing.” Pulsed laser technology significantly improves the efficiency of large-area processing. In the future, as the demand for precision manufacturing continues to grow in industries like new energy and microelectronics, laser etching will gradually replace traditional etching in more areas, becoming the core force behind industrial “precision engraving.” Understanding the core differences between the three etching technologies is crucial for selecting the appropriate processing solution and improving production efficiency.