In the field of industrial identification, “marking” is a critical step in product traceability, brand anti-counterfeiting, and functional labeling. With the advancement of technology, laser technology, represented by fiber marking machines, is competing with traditional marking methods such as ink printing, pneumatic coding, and electrochemical etching. What are the core differences between the two? From technical principles to practical applications, these differences directly impact a company’s production efficiency and cost control.

- 1.Working Principle: The Essential Difference Between “Invisible Laser” and “Physical Contact”

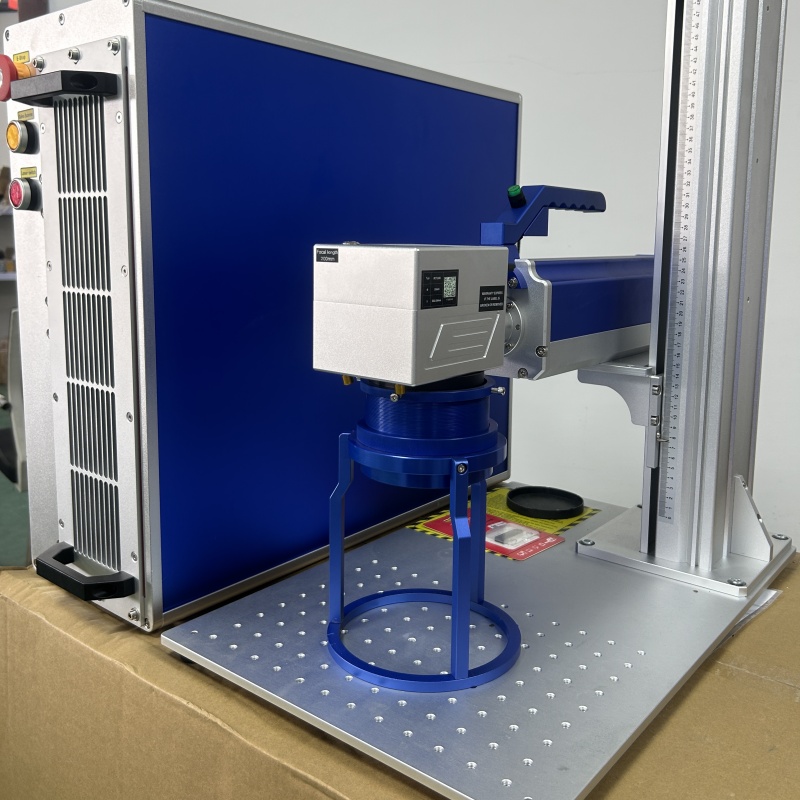

Traditional marking methods often rely on “physical/chemical contact” to achieve marking. For example, ink printing requires a printhead to deposit pigment onto the product surface, pneumatic coding relies on a metal needle to impact the material to create an indentation, and electrochemical etching uses chemical reactions to corrode the surface. These methods generally suffer from the limitations of “contact operation”—not only can they easily scratch delicate parts, but they can also affect product performance due to residual consumables, such as ink contamination of electronic components. Fiber optic marking machines operate on the principle of laser beam action. They generate high-energy-density laser light from a fiber laser. Once focused, they instantly create microscopic physical changes on the surface of the material (such as oxidation on metals and carbonization on plastics), marking the material without any physical contact. This non-contact feature avoids material damage while enabling precise operation on curved surfaces and tiny workpieces. Examples include marking QR codes on mobile phone chips and marking scales on medical needles, which are difficult to achieve with traditional marking.

- 2.Core Performance: A Complete Overmatch in Precision, Efficiency, and Stability

In industrial production, marking accuracy and efficiency directly determine product competitiveness. Traditional marking methods generally have an accuracy of above 0.1mm, and ink printing is prone to smudging and fading. Pneumatic marking is subject to needle wear, and the clarity of the mark decreases over time. For example, in the marking of automotive parts, traditional methods struggle to meet the requirements for engraving the tiny characters of VIN codes (vehicle identification numbers), often resulting in blurred markings and difficulties in traceability. Fiber optic marking machines achieve precision of 0.01mm, equivalent to 1/10 the diameter of a human hair, making them capable of easily engraving micron-level characters and complex patterns. More crucially, their efficiency advantage lies in their efficiency: Traditional ink printing requires a drying period, taking several seconds per piece. Fiber optic marking machines, however, can mark hundreds of characters per second with no waiting time, increasing efficiency by 3-5 times in mass production. Furthermore, fiber lasers offer a lifespan of up to 100,000 hours and require virtually no maintenance. Traditional marking equipment, however, requires regular replacement of consumables such as needles and inks, making them far less reliable.

- 3. Cost and Environmental Protection: Long-Term Economic Benefits vs. Short-Term Low Prices

In terms of initial investment, traditional marking equipment (such as ink printers) typically costs several thousand to tens of thousands of yuan, far less than fiber optic marking machines (typically 30,000 to 100,000 yuan). However, in terms of long-term operating costs, fiber optic marking machines offer a significant advantage. Traditional marking requires the continuous purchase of consumables such as ink, needles, and etching fluid. For a company producing 100,000 products annually, annual consumable costs can reach tens of thousands of yuan. Fiber optic marking machines, on the other hand, require no consumables other than electricity, resulting in an average annual operating cost of only a few hundred yuan, typically paying for themselves in two to three years.

Environmental issues also present a key difference between the two. Traditional marking inks and etching fluids contain toxic chemicals, requiring additional costs for wastewater and exhaust gas treatment and potentially facing regulatory pressure from environmental authorities. Fiber optic marking machines emit no pollutants, aligning with current “green manufacturing” policy trends and making them particularly suitable for environmentally stringent industries such as electronics, medical, and food.

- 4. Application Scenarios: Each with its own focus, not a complete replacement

Despite the obvious advantages of fiber optic marking machines, traditional marking methods still have specific applications. For example, on flexible materials like paper packaging and plastic film, the cost advantage of ink printing remains difficult to replace. On rough casting surfaces, the deep marking effect of pneumatic coding is more suitable. Fiber optic marking machines, on the other hand, dominate the field of high-precision, high-hardness materials, such as metals (stainless steel, aluminum alloys), ceramics, and glass, as well as precision products like electronic components, medical devices, and jewelry. With technological advancements, fiber optic marking machines are continuously expanding their application boundaries. For example, the recent rise of “color marking” technology enables multi-color marking on metal surfaces, further replacing some traditional spray coating processes.

- 5.Conclusion: The Logic of Choice Under Technological Iteration

The difference between fiber optic marking machines and traditional marking is essentially the generational gap between “laser technology” and “traditional physical/chemical technologies.” For companies pursuing high precision, high efficiency, and long-term economic benefits, fiber optic marking machines are the inevitable choice. However, for short-term needs for low-precision, low-cost, and flexible materials, traditional marking still has room for survival. As the manufacturing industry transitions toward “intelligentization and greening,” the application scope of fiber optic marking machines will continue to expand, becoming a mainstream technology in the industrial marking field.