In precision manufacturing and materials processing, etching is a core process for achieving fine patterns, functional textures, and precise cuts. As industry demands for precision, efficiency, and environmental protection increase, laser etching machines, with their advantages such as non-contact processing and high flexibility, are gradually replacing traditional chemical etching and mechanical engraving, becoming the preferred technology in industries such as electronics, medical, and aerospace. From technical principles to practical applications, how have laser etching machines reshaped the processing process, and why have they become a key piece of equipment for efficient production?

- Technical Principle: “Photothermal/Photochemical Action” Breaks the Limitations of Traditional Processing

Traditional etching technologies rely on physical contact or chemical etching, presenting significant bottlenecks. Chemical etching requires immersing the material in a corrosive solution and controlling the etching area using a mask. This is prone to precision deviations due to solution penetration and produces large amounts of wastewater containing heavy metals, resulting in high environmental disposal costs. Mechanical engraving, on the other hand, relies on high-speed rotating tools to cut the material. When working with hard metals and ceramics, the tools wear quickly and easily scratch the workpiece surface, making it particularly challenging for micron-level precision machining.

Laser etching machines operate based on the principle of “light energy interaction.” Lasers generate laser light of a specific wavelength (such as fiber lasers or CO₂ lasers), focusing it into a high-energy-density spot that impacts the surface of the material. Depending on the material’s properties, lasers can achieve two core etching effects: the photothermal effect, in which the laser energy instantly heats the material, causing it to partially melt, vaporize, or undergo a phase change, resulting in indentations or cut marks. This is suitable for hard materials such as metals and ceramics. The photochemical effect, in which the laser energy breaks the chemical bonds between the material’s molecules, causing the surface material to decompose and volatilize. This is suitable for materials susceptible to heat deformation, such as plastics and glass. The entire process requires no physical contact and does not rely on chemical reagents, fundamentally addressing the precision and environmental challenges of traditional etching.

- 2. Core Advantages: A Triple Breakthrough in Precision, Efficiency, and Flexibility

In precision machining applications, laser etching machines offer particularly outstanding precision advantages. Its minimum etching line width can reach 10 microns (approximately 1/7 the diameter of a human hair), with repeatability accuracy within ±0.001mm. This makes it easy to process complex microcircuits, fine textures, and tiny holes. For example, in the electronics industry, laser etching machines can engrave micron-scale circuit patterns on mobile phone circuit boards with far greater precision than traditional chemical etching. In the medical field, they can etch non-slip textures on stainless steel surgical instruments without compromising the overall strength and finish of the instruments.

Efficiency improvements are key to enabling mass production of laser etching machines. Traditional chemical etching requires multiple steps, including mask preparation, soaking, and cleaning, and can take up to several minutes to complete a single part. Laser etching machines, on the other hand, enable “open-and-run” processing, achieving speeds of several meters per second. For mass-produced parts, this can increase processing efficiency by 5-10 times. More importantly, laser etching eliminates the need for drying or chemical reaction time; the next step can be moved immediately upon completion, significantly shortening production cycles. Taking automotive parts processing as an example, a laser etcher can complete the etching of dozens of engine sensor logos and textures in just one minute, while traditional mechanical engraving would take over 10 minutes.

Flexibility is the core capability of laser etchers, enabling them to adapt to diverse application needs. Through software programming, laser etchers can quickly switch processing patterns, adjust etching depth, and speed, without changing molds or tools. This makes them particularly suitable for small-batch, high-variety customized production. For example, in the jewelry industry, designers simply import their designs into the system, and the laser etcher can engrave personalized patterns on precious metals like gold and platinum, with a transition time of less than five minutes from design to finished product. In the packaging industry, laser etchers can adjust information such as the production date and QR code on plastic packaging in real time to meet varying product specifications, offering far greater flexibility than traditional printing equipment.

- 3. Applicable Scenarios: Covering Processing Needs in Multiple Industries

Laser etchers have penetrated numerous key industries, becoming a core piece of equipment for differentiated processing. In the electronics and information technology sector, laser etching machines are used for micro-etching circuit boards, marking and cutting chips, and etching ITO conductive films for flexible displays, ensuring miniaturization and high performance in electronic products. In aerospace, laser etching machines can etch positioning lines for high-temperature-resistant coatings on the surfaces of aviation materials such as titanium and aluminum alloys, or create cooling holes for engine blades, meeting the demands of extreme environments. In the new energy sector, they can etch tabs on lithium battery electrodes, improving the battery’s energy density and charge-discharge efficiency.

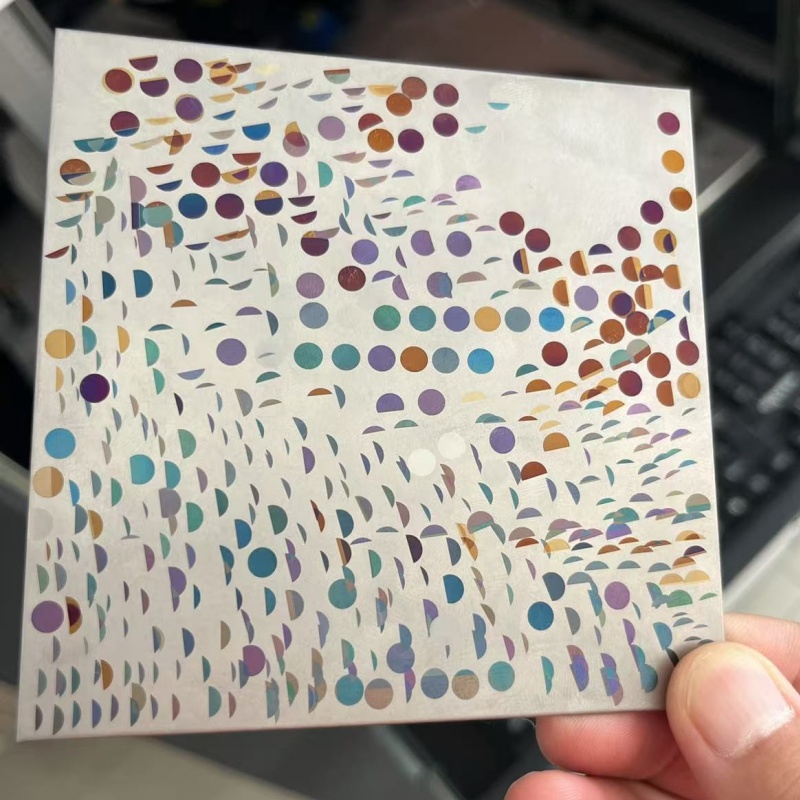

Even in areas where traditional processing is dominant, laser etching machines are gradually replacing them. For example, in glass processing, traditional mechanical engraving is prone to shattering, while laser etching machines, by controlling energy density, can create fine patterns or graduations on the glass surface without the risk of shattering. In plastic processing, laser etching can replace ink printing, creating permanent markings on plastics such as ABS and PC, avoiding ink bleed or contamination. IV. Selection and Maintenance: Balancing Performance and Long-Term Cost-Effectiveness

When choosing a laser etching machine, companies should focus on three key indicators: First, the laser type. Fiber lasers are suitable for hard materials like metals and ceramics, CO₂ lasers are suitable for non-metallic materials like plastics and wood, and UV lasers are ideal for high-precision glass and semiconductor processing. Second, the processing format and power: choose a worktable format that matches the workpiece size, and select the appropriate laser power based on the material thickness and etching depth. Third, the software and control system should ensure ease of operation, support for importing multiple image formats, and reliable fault warning capabilities.

In terms of maintenance, the core advantage of laser etching machines lies in their low maintenance costs. The laser has a lifespan of up to 100,000 hours (approximately 11 years) without requiring core component replacement. The equipment only requires regular lens cleaning and optical path stability checks, resulting in an average annual maintenance cost of only a few hundred yuan, far lower than the consumables and repair costs of traditional etching equipment.

- 4.Conclusion: New Processing Options Under Technological Upgrades

The rise of laser etching machines is essentially a natural result of the demand for “high-precision, high-efficiency, and low-pollution” processing in precision manufacturing. It not only breaks the limitations of traditional etching technology but also empowers product upgrades and capacity increases across multiple industries through technological innovation. With the continuous iteration of laser technology, laser etching machines will develop towards higher precision, higher power, and greater intelligence in the future, further covering cutting-edge fields such as semiconductors and quantum technology, becoming a key equipment driving high-quality development in the manufacturing industry. For companies pursuing processing quality and production efficiency, choosing a laser etching machine means choosing a high-efficiency processing solution that conforms to technological trends.