With the growing demand for smart manufacturing and personalized customization, small laser marking machines, with their flexibility, efficiency, and low cost, have become core equipment in industries such as electronic components, jewelry, medical devices, and gift customization. However, the market is flooded with models and their specifications vary widely. Failure to select the right model can not only increase procurement costs but also impact production efficiency and product quality. This article will provide scientific selection guidelines for businesses and individuals by focusing on key selection factors, common pitfalls, and industry-specific solutions.

- I. Key Selection Factors: Five Dimensions for Accurately Matching Requirements

The essence of model selection lies in “precisely matching requirements with equipment performance.” Analysis should focus on the following five core dimensions, avoiding blind pursuit of specifications or price.

- Identify the Marking Material: The Key to Determining the Laser Type

Different materials exhibit significant differences in their absorption and reaction to lasers, which is the primary prerequisite for model selection. Currently, mainstream small laser marking machines fall into three main categories:

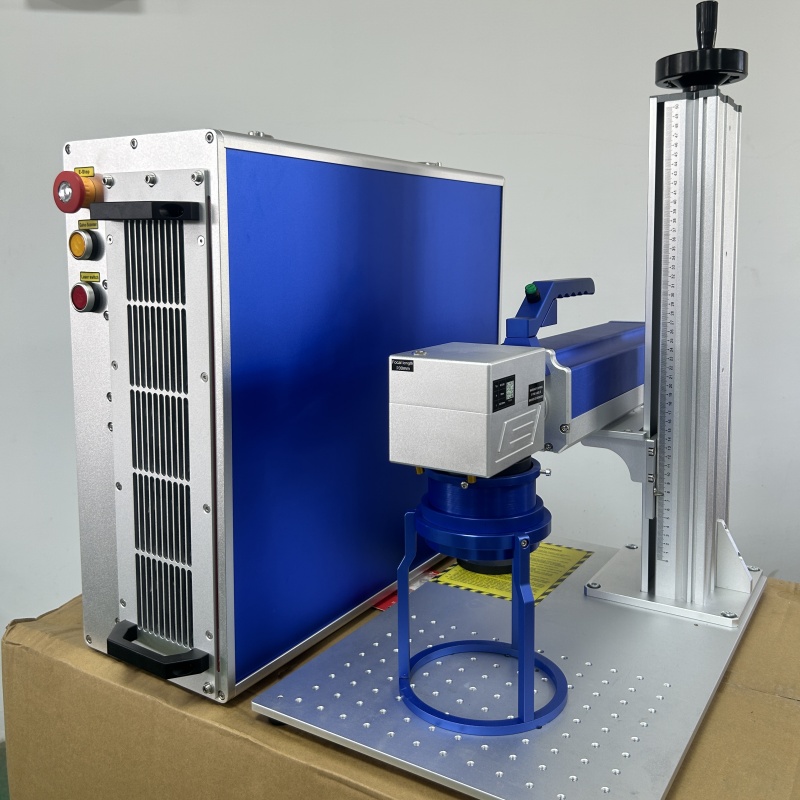

Fiber laser marking machines: Suitable for metals (stainless steel, aluminum alloy, copper), alloys, and some non-metallic materials (ABS, PC). They offer clear, wear-resistant markings and high speed, making them the preferred choice for the electronics and hardware industries. For example, when marking serial numbers on metal mobile phone frames, fiber lasers can achieve permanent markings with 0.1mm accuracy.

CO₂ laser marking machines: Targeting non-metallic materials such as wood, acrylic, paper, leather, glass (with coating), and plastics (PVC, PP), they are suitable for gift customization and packaging printing. Their advantages lie in their low cost and ability to produce delicate engravings, such as intricate patterns on wooden gift boxes.

UV laser marking machines: Primarily focusing on “cold processing,” they are suitable for heat-sensitive materials (PVC film, flexible circuit boards), transparent materials (glass, sapphire), and applications requiring high precision (medical devices, chips). For example, when marking graduations on medical syringes, UV lasers can prevent material deformation and achieve accuracy of 0.01mm. If the material is unclear, it’s recommended to provide samples to the supplier for testing. Determining the laser type based on the marking results is a key step in avoiding selection errors.

- Determine the Marking Format and Accuracy: Balancing Efficiency and Requirements

The standard formats for small laser marking machines are mostly 100mm×100mm or 150mm×150mm. Some can achieve larger formats (e.g., 300mm×300mm) by adding extension lenses. When selecting a model, consider the workpiece size:

For smaller workpieces (such as electronic components or jewelry), a 100mm×100mm format is sufficient. A smaller format will reduce efficiency, while a larger format may increase equipment costs.

For marking large areas (such as gift boxes or furniture panels), an extended format is recommended. However, be aware that the larger format may slightly reduce edge accuracy.

In terms of accuracy, the minimum line width for fiber laser marking machines can reach 0.01mm, while that for CO2 laser marking machines is approximately 0.02mm. Marking on ordinary hardware requires lower precision (0.1mm is sufficient), while medical devices, chips, and other applications require high-precision models to avoid blurred markings due to insufficient precision.

- Evaluating Production Efficiency: Matching Production Capacity Requirements

Efficiency primarily depends on laser power and marking speed. Small laser marking machines typically have power ranges of 20W-50W (fiber), 30W-100W (CO₂), and 5W-15W (UV). Higher power increases marking speed, but also increases cost and energy consumption.

For small-batch customization (e.g., gift shops): A 20W fiber or 30W CO₂ machine is sufficient, balancing cost and efficiency.

For large-volume production (e.g., electronics factories): A 30W-50W fiber machine is recommended, which can increase marking speed by 30%-50% and reduce line wait time.

For high-precision, slow-moving processes (e.g., medical devices): A 5W-10W UV machine is more suitable. While slower, it ensures marking quality. In addition, the device’s software compatibility can also affect efficiency. Prioritize models that support formats like CAD and AI and can batch import files to reduce manual operation time.

- Focus on device stability and after-sales service

The core components of a small laser marking machine (laser generator, galvanometer, and control card) directly determine its stability. Laser generators from mainstream brands (such as IPG and Raycus) have a lifespan of over 100,000 hours, while galvanometers (such as Scanlab) offer higher positioning accuracy. However, inferior components may fail after one to two years of use, increasing repair costs.

After-sales service is also crucial. Verify whether the supplier provides:

Installation and commissioning services: Especially for novice users, professional installation can prevent equipment damage caused by improper operation.

Warranty period: Core components are recommended to have a warranty of at least two years, and the entire machine should have a warranty of at least one year.

Repair response speed: Whether there is a local service point and whether the response time is within 24 hours to avoid equipment downtime that may affect production.

- Cost and Budget Calculation: Balancing Short-Term Investment and Long-Term Benefits

Small laser marking machines have a wide price range: 20W fiber lasers range from approximately 15,000 to 30,000 RMB, 30W CO₂ lasers range from approximately 10,000 to 20,000 RMB, and 10W UV lasers range from approximately 30,000 to 50,000 RMB. When selecting a model, consider “purchase cost + operating cost + maintenance cost”:

Purchase cost: Avoid blindly pursuing the lowest price. Low-priced models may use inferior components, resulting in higher repair costs.

Operating cost: Fiber optic models have lower energy consumption (approximately 0.5 kWh/hour), while CO₂ models consume slightly more (approximately 1 kWh/hour). Long-term energy consumption differences should be considered.

Maintenance cost: Fiber optic models are simple to maintain, requiring only regular lens cleaning. CO₂ models require laser tube replacement (lifespan approximately 8,000-10,000 hours, cost approximately 2,000 yuan). UV models have more expensive lenses (replacement cost approximately 5,000 yuan), so this should be factored into your long-term budget.

- Common Selection Mistakes: Avoid These Pitfalls

- Blindly Pursuing High Power: Higher Power Isn’t Always Better

Some users believe that “higher power means better marking results,” but this is not the case. For example, using a high-power fiber laser on plastic can cause scorching and deformation. On metal, for shallow marking, a 20W power rating is sufficient; choosing a 50W model will only increase costs and energy consumption.

- Ignoring Software Functionality: Operational Ease Impacts Efficiency

Many users focus solely on hardware specifications, neglecting the software experience. Low-quality software can lead to issues such as file import delays, batch marking errors, and complex parameter adjustments, ultimately reducing production efficiency. It’s recommended to test the software on-site before selecting a model, prioritizing models with a simple interface and support for automatic positioning (such as vision positioning systems).

- Ignoring Workpiece Clamping Requirements: Compatibility Impacts Marking Quality

Most small laser marking machines are desktop models. Irregular workpiece shapes (such as round or curved) require additional auxiliary equipment such as rotary axes and fixtures. Failure to consider this in advance can lead to offset marking positions, necessitating secondary purchases and increasing costs.

III. Industry-Specific Model Selection Recommendations

- Electronic Components Industry

Requirements: Metal casing marking (serial numbers, QR codes), high precision, and high efficiency.

Selection: 30W-50W fiber laser marking machine with a vision positioning system, 150mm×150mm format, ensuring rapid workpiece position identification and preventing marking deviations.

- Custom Gift Industry

Requirements: Compatibility with multiple materials (wood, acrylic, metal), intricate patterns, and flexible small-batch production.

Selection: 20W fiber laser + 30W CO₂ dual laser model (if budget permits), or a 20W fiber laser (primarily for metal) + 30W CO₂ laser (primarily for non-metal). A 100mm×100mm format will accommodate most gift sizes.

- Medical Device Industry

Requirements: High precision, zero deformation, and permanent marking.

Selected Model: 10W-15W UV laser marking machine with a 100mm x 100mm format. Ensures clear, damage-free marking on heat-sensitive materials such as syringes and surgical instruments, and complies with medical industry standards.