In recent years, food safety incidents have occurred frequently. Counterfeit and substandard food products not only infringe upon consumers’ health rights but also seriously disrupt market order. In the construction of food traceability and anti-counterfeiting systems, packaging, as the “first line of defense” directly facing consumers, urgently needs an upgrade in anti-counterfeiting technology. Traditional anti-counterfeiting methods, such as coding and labeling, are easily imitated and easily detached, failing to meet the current market’s demand for high-security and high-stability anti-counterfeiting. Against this backdrop, laser marking machines, with their advantages of precision, permanence, and environmental friendliness, are becoming a new choice for anti-counterfeiting in food packaging, injecting new momentum into safeguarding food safety.

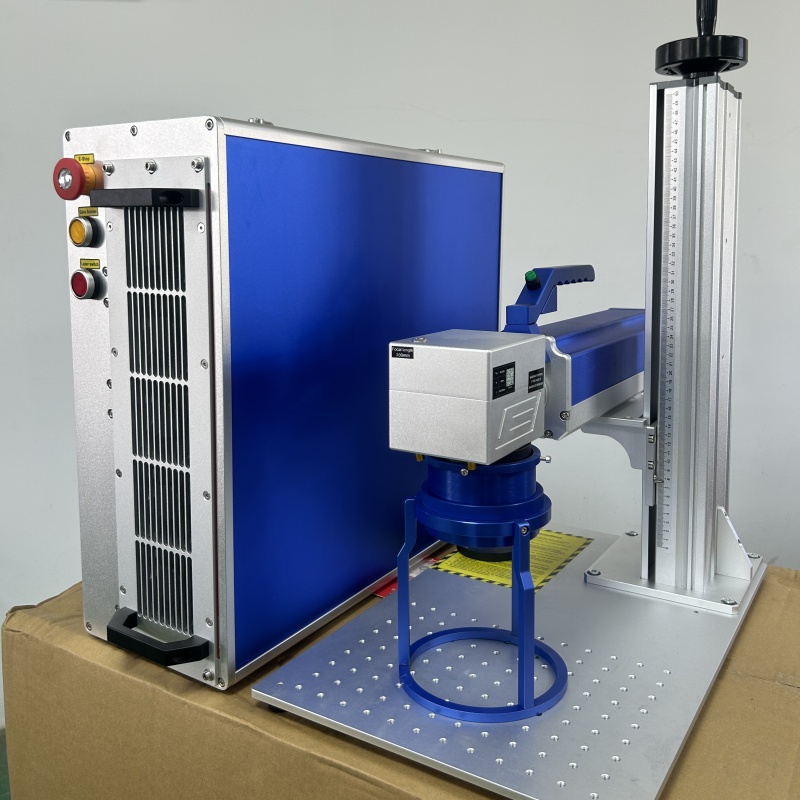

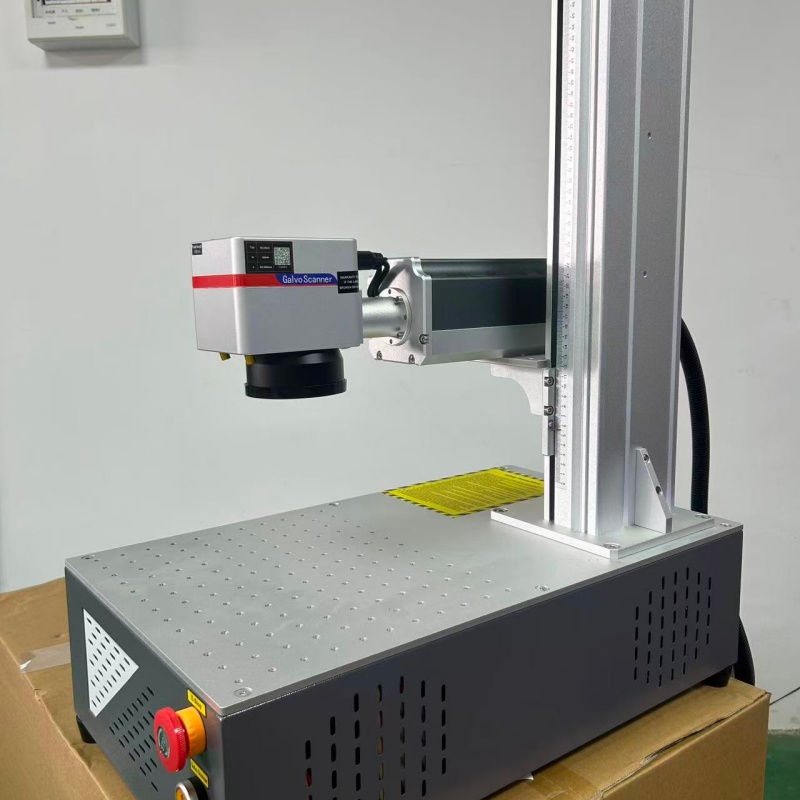

Laser marking machines are devices that use a laser beam to etch permanent markings onto the surface of food packaging materials. Their working principle involves generating high-energy laser light, which, after focusing, acts on the packaging surface, causing physical or chemical changes in the material, thereby forming clear and detailed text, patterns, QR codes, and other markings. Compared with traditional anti-counterfeiting technologies, laser marking has significant advantages. First, laser marking offers strong anti-counterfeiting capabilities. The laser marking penetrates deep into the packaging material, making it difficult to wipe, alter, or counterfeit. Customized anti-counterfeiting patterns and encrypted QR codes can be added to meet specific business needs, enabling precise traceability with a unique code for each item. Consumers can easily verify authenticity by scanning the code with their mobile phones to check the production batch, origin, and testing reports.

Second, environmental friendliness and safety are crucial characteristics that make laser marking machines suitable for food packaging. Food packaging has extremely high safety requirements. Traditional inkjet printing technology may use inks containing harmful substances that could migrate into food. Laser marking eliminates the need for inks, solvents, and other chemicals, resulting in zero pollutant emissions. This avoids chemical contamination of food and aligns with the trend towards green packaging. Furthermore, laser marking produces no dust or noise pollution, making it environmentally friendly and helping food companies achieve cleaner production.

Furthermore, laser marking machines are characterized by their wide applicability and excellent marking results. Food packaging materials are diverse, including plastics, glass, metals, paper, and films. Laser marking machines can adjust laser parameters according to the characteristics of different materials to achieve efficient marking. Whether etching production dates and expiration dates on plastic bottle caps, marking brand logos and traceability codes on metal cans, or printing anti-counterfeiting patterns on paper packaging, laser marking ensures clear, aesthetically pleasing, and wear-resistant markings without affecting the packaging’s seal and integrity.

In practical applications, laser marking machines have become essential equipment for many food companies to enhance their anti-counterfeiting capabilities. For example, in the dairy industry, companies use laser marking machines to print QR codes containing production and quality inspection information on milk cartons and yogurt bottles. Consumers can scan the codes to access product lifecycle data, effectively preventing counterfeit dairy products from entering the market. In the liquor industry, laser marking machines engrave unique anti-counterfeiting marks and traceability codes on bottle caps and bodies, not only enhancing the product’s anti-counterfeiting level but also increasing consumer trust in the brand. In the snack food industry, laser marking machines print anti-counterfeiting patterns and production dates on packaging bags, solving the problems of traditional inkjet printing being easily tampered with or detached, thus ensuring product quality and safety.

As the food industry’s requirements for anti-counterfeiting and traceability continue to increase, laser marking machine technology is also continuously innovating and upgrading. In the future, laser marking machines will develop towards higher precision, faster speed, and greater intelligence, enabling more complex anti-counterfeiting pattern designs and more efficient batch marking operations. Simultaneously, by combining with technologies such as the Internet of Things and big data, a more comprehensive food anti-counterfeiting and traceability system will be built. Furthermore, specialized laser marking equipment will continue to emerge to address the characteristics of different food packaging materials, further expanding the application scenarios of laser marking machines in the field of food packaging anti-counterfeiting.

In summary, laser marking machines, with their outstanding advantages such as permanence, high anti-counterfeiting performance, and environmental friendliness and safety, break through the limitations of traditional food packaging anti-counterfeiting technologies, providing a completely new solution for food packaging anti-counterfeiting. In today’s world, where food safety is increasingly valued, laser marking machines will undoubtedly see wider application in the food packaging industry, helping food companies improve product quality and safety levels, maintain market order, and protect consumers’ legitimate rights and interests.