Industrial laser machines have become an increasingly important tool in manufacturing processes. Laser welding and laser cutting have revolutionized the way companies operate, providing them with precision, speed, and efficiency that were previously unimaginable. As technology continues to advance, the future of industrial laser machines looks brighter than ever, with new applications and capabilities being developed every day.

Laser Welding

Laser welding is the process of joining two metal parts together using a laser beam. This technique is increasingly popular in industries such as automotive, aerospace, and electronics. The precision of the laser beam ensures that the weld is strong and that the parts are joined seamlessly, without the need for additional materials such as screws or rivets.

One of the most significant advancements in laser welding is the development of remote welding technology. This technology allows operators to weld parts without being physically present, which reduces the risk of injury and increases efficiency. Remote welding technology is especially useful for welding large or bulky parts that are difficult to move.

Another area of development is the use of fiber lasers for welding. Fiber lasers are more energy-efficient than traditional lasers and can be used to weld a wider range of materials. Additionally, they are smaller and more portable, making them ideal for on-site repairs and maintenance.

Laser Cutting

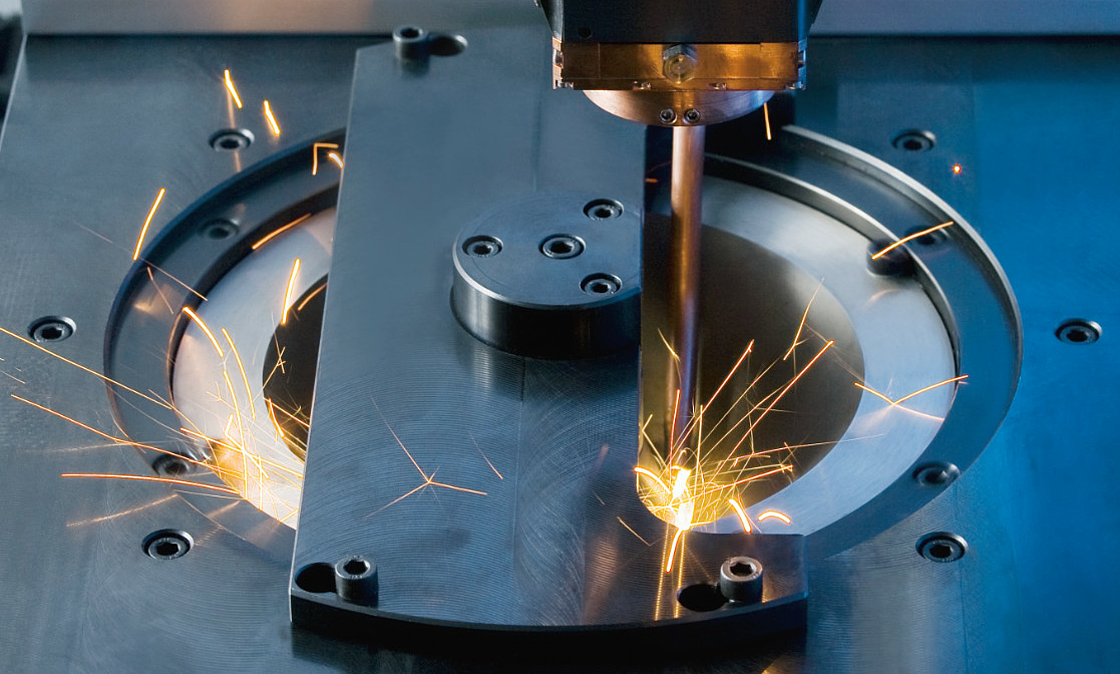

Laser cutting is the process of using a laser beam to cut through a material such as metal, plastic, or wood. This technique is widely used in industries such as automotive, aerospace, and construction. Laser cutting provides precision and accuracy that cannot be achieved with traditional cutting methods.

One area of development in laser cutting is the use of 3D printing. 3D printing allows manufacturers to create complex shapes and designs that were previously impossible to produce with traditional cutting methods. By combining 3D printing with laser cutting, manufacturers can create intricate and precise parts with ease.

Another area of development is the use of automation. Automated laser cutting machines can process large volumes of material quickly and efficiently, reducing labor costs and increasing productivity. Automated laser cutting machines can also be programmed to cut parts to precise specifications, reducing waste and improving quality.

Conclusion

The future of industrial laser machines, including laser welding and laser cutting, is bright. As technology continues to advance, new applications and capabilities are being developed every day. From remote welding technology to fiber lasers for welding, and 3D printing combined with laser cutting, the possibilities are endless. The use of automation and the ability to process large volumes of material quickly and efficiently will continue to drive productivity and reduce costs, making laser machines an essential tool for manufacturers across industries.