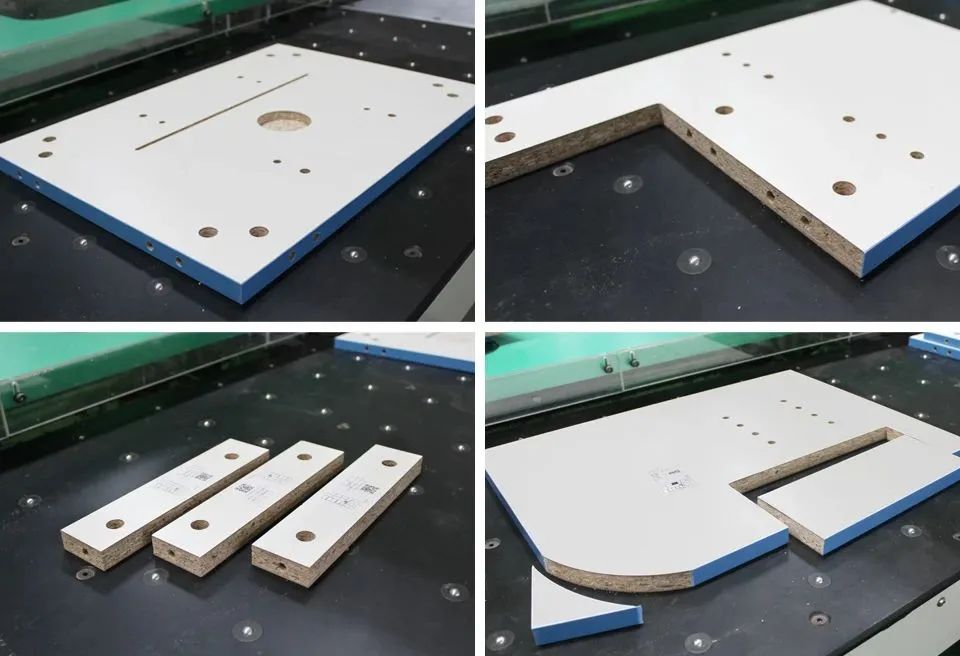

PTP nesting tech can proceed cutting, milling, drilling and grooving for the panel furniture. Support intelligent customization with high efficiency, stability and processing diversity. With all this advantage, it's cost effective and meets the needs of batch production.

2 pcs of workpiece alternately process which improves efficiency.

Six pcs moveable bar, flexible layout,loading unloading material is easy

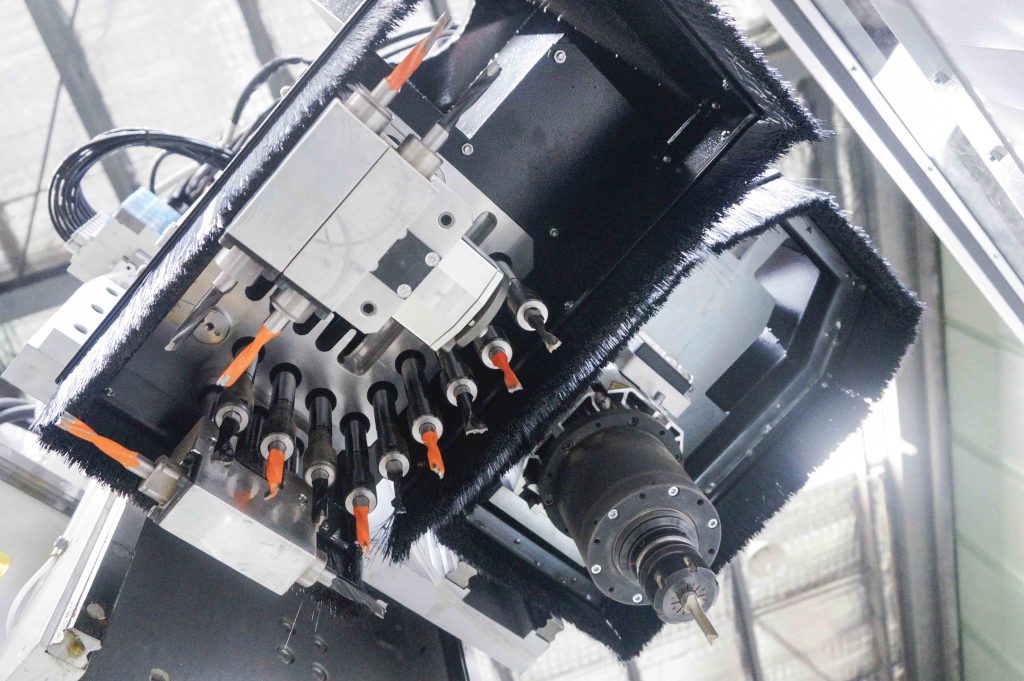

Fast and accurate in tool auto-change, which meets the demands on multi-machining with different tools.

Maximum speed up to 24000rpm, which satisfies the needs on high-speed routering.

Continuous drilling according to production requirements, to realize efficient drilling and grooving.

Optional

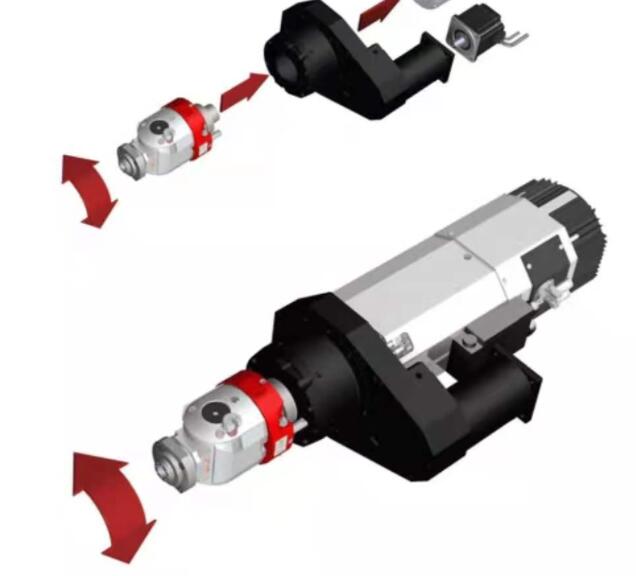

It can be used with various aggregate to achieve special processes such as side cutting and 45° Lamello grooving

| Series Item | PWD 1230 | PWD1252 |

| Traveling Size | 3400*1640*250mm | 5550*1640*250mm |

| Working Size | 3060*1260*100mm | 5200*1260*100mm |

| Table Size | 3060*1200mm | 5200*1200mm |

| Transmission | X/Y rack and pinion drive;Z ball screw drive | |

| Table Structure | Pods and Rails | |

| Spindle Power | 9.6 KW / 11KW /12KW air or water cooling spindle | |

| Spindle Speed | 24000r/min | |

| Traveling Speed | 80m/min | |

| Working Speed | 20m/min | |

| Tool Magzine | Carousel | |

| Tool Slots | 8 pcs ( Optional 12 pcs 24 pcs ) + 4 or 6 pcs liner tool change | |

| Drilling Bank | 9 Vertical+3 Horizontal+1 Saw ( optional: 14+3+2 ) | |

| Driving System | Yaskawa /Syntec | |

| Voltage | AC380/50HZ | |

| Controller | Osai /Syntec | |

| Vacuum pump | Germany Becker vacuum pump | |

| Optional | C axis five axis | |

PTP processing center is popular used in wood cabinet factory. It is very conivent for making side hole also can make lock hole.

Cabint body drilling cutting show

1. Contact with us by mail or whatsapp, let us talk clearly what kind of cabinet making,we need know your material information, such as length,width and thickness, material is MDF or solid wood.

2. We need to know more about your processing. You want cutting, engraveing, drilling or you need side drilling hole? And we we will know you only need spinde working or need choose drilling bank?

3.We made clearly your working and then we need to know how is your invest. Because this machine can assemble with different specification. Such as spindle, our standard is HSD brand with power 9.6KW 11KW. If your invest limited, you can consider Chinese famous brand, quality also very good.

4. According to your work, we need to know you need softwate or not, normaly for cabinet factory has their own software, we need to know if your software can use on PTP processing center or not.

phone: +8613791007598

[email protected]