1. High-Precision Cutting

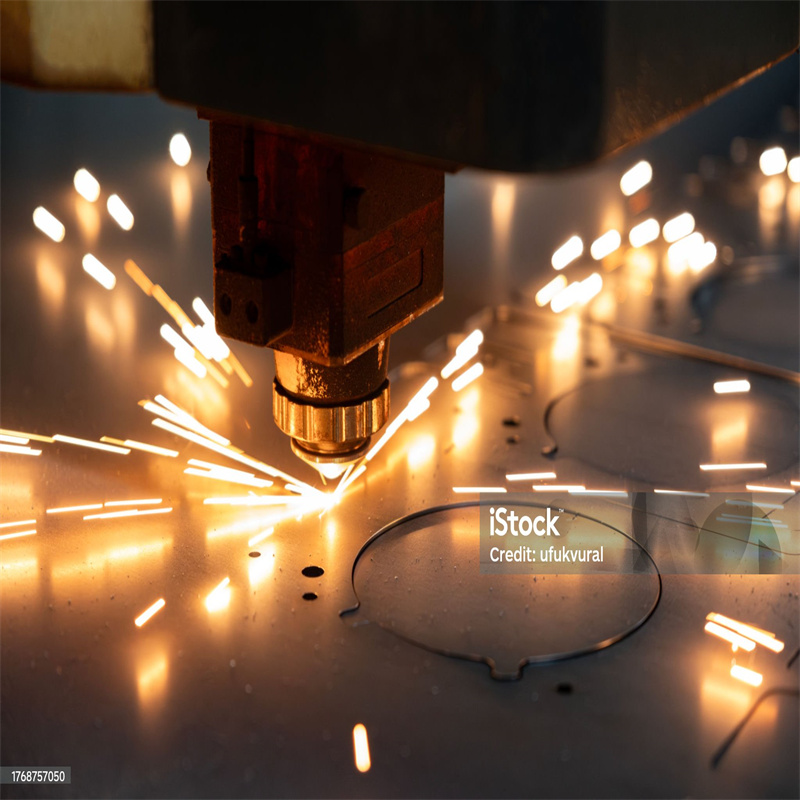

The laser beam can be focused into an extremely small spot, endowing laser cutting machines with extremely high cutting precision. Their positioning accuracy usually reaches ±0.05 mm, enabling them to easily cut complex and intricate patterns. Moreover, the width is extremely narrow, generally between – 0. 0.13 mm. This is undoubtedly a great advantage for industries with strict precision requirements, such as electronics and precision machinery manufacturing. For example, in the cutting of electronic chips, laser cutting machines can accurately cut the chips into the required size and shape, avoiding chip damage caused by insufficient cutting precision and greatly improving the product yield.

2. High-Speed Cutting

The high energy density characteristic of lasers enables the cutting process to proceed rapidly, with cutting speeds reaching several meters per minute, far exceeding traditional cutting methods. In large-scale production scenarios, the advantages of this high-speed cutting are particularly evident. For instance, in the automotive manufacturing industry, a large number of metal sheets need to be cut and processed. Laser cutting machines can complete a large number of cutting tasks in a short time, significantly improving production efficiency, shortening the product production cycle, and helping enterprises gain the upper hand in the fierce market competition.

3. Excellent Cutting Quality

The cut surface of the workpiece after laser cutting is very smooth, and almost no secondary processing is required. At the same time, the heat-affected zone is extremely small, which means that the properties of the surrounding materials are hardly affected. In the aerospace field, for the manufacturing of some key components, the stability of material properties is highly required. Laser cutting machines can maintain the original properties of the materials to the greatest extent during the cutting process, ensuring the quality and reliability of the components and providing a strong guarantee for the safe operation of aerospace equipment.

4. Wide Material Adaptability

Laser cutting technology can handle various types of materials. Whether it is metal materials such as stainless steel, carbon steel, and aluminum alloy, or non-metal materials such as plastics, wood, and acrylic, and even composite materials, it can be easily processed without being limited by material hardness. This wide material adaptability enables laser cutting machines to play an important role in different industries. In the architectural decoration industry, laser cutting machines can be used to cut metal profiles to make exquisite decorative frames and also cut acrylic sheets to create unique decorative shapes, meeting diverse design requirements.

5. Effective Reduction of Material Waste

Due to the very narrow kerf of laser cutting, the utilization rate of materials can be maximized during the cutting process, reducing the generation of waste. For some expensive materials, such as rare metals and high-performance composite materials, this advantage is particularly important. For example, in the jewelry processing industry, when using laser cutting machines to cut precious metal materials, they can accurately cut out the required shapes, reducing material waste, lowering production costs, and improving the economic benefits of enterprises.

6. Safe Operation and Environmentally Friendly

Laser cutting is a non-contact processing method. Operators do not need to directly contact the cutting tools and materials, reducing the risk of injury due to improper operation. At the same time, the equipment generates little noise during operation and does not produce a large amount of dust and harmful chemicals, creating a relatively safe and comfortable working environment for operators. In industries with strict production environment requirements, such as food packaging and pharmaceuticals, this advantage of laser cutting machines makes them an ideal cutting equipment, which can not only ensure the safety and hygiene of production but also meet environmental protection standards.

7. Saving on Die Investment

Traditional cutting processes often require the production of a large number of dies, which are not only costly but also have a long production cycle. For the production of small batches and multiple varieties of products, the frequent replacement and maintenance of dies further increase the cost. In contrast, laser cutting machines can directly cut various workpieces without the need for dies. Just design the cutting graphics on the computer and import them into the control system to start cutting. This feature enables enterprises to quickly respond to market demands, flexibly adjust production plans, and is especially suitable for new product research and development and small-batch customized production, greatly reducing production costs and time costs.

8. Low Post-Maintenance Costs

Laser cutting machines have stable performance and a relatively simple structure, and key components such as lasers have a long service life. Compared with some complex mechanical cutting equipment, their post-maintenance workload and costs are lower. For example, traditional mechanical punching machines require regular maintenance and replacement of dies, transmission components, etc., with high maintenance costs and long downtime. In normal use, laser cutting machines only require simple daily maintenance, such as cleaning the equipment and checking the optical path, to ensure the stable operation of the equipment, reducing production interruptions caused by equipment failures and improving the production efficiency and economic benefits of enterprises.