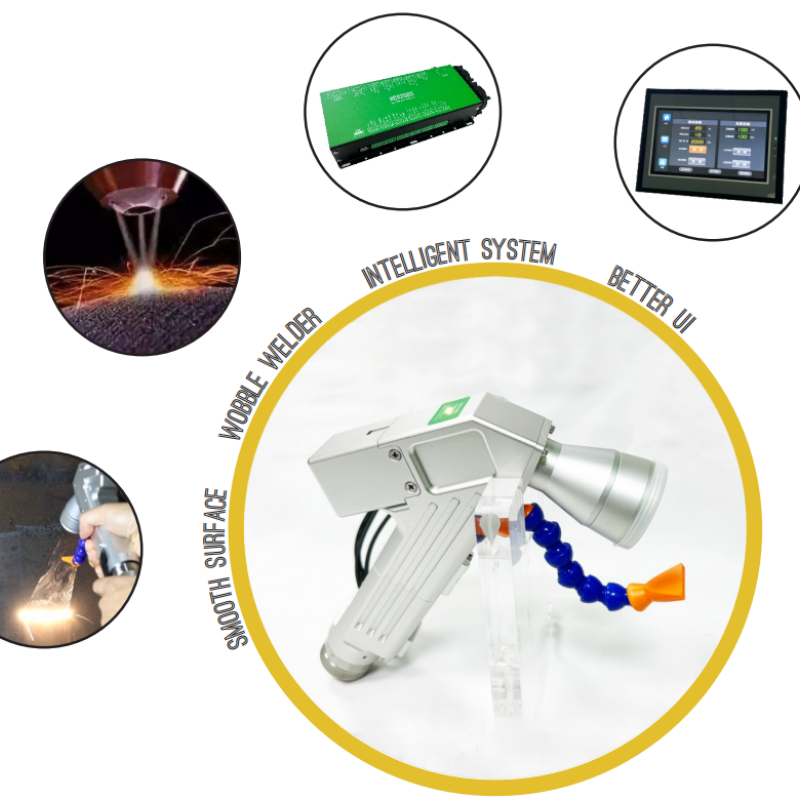

Our 4 in 1 handheld laser welding and cleaning machine innovatively integrates four core functions: laser cleaning, cutting, welding, and weld seam cleaning, achieving a high – level integration of multi – process processing.

Thanks to this unique all – in – one design, the device can meet the full – process requirements from surface pre – treatment to fine processing and then to post – welding treatment in one stop, bringing an unprecedented convenient and efficient experience to industrial production. Next, I will introduce in detail the applicable scenarios of this device and its differences from other laser equipment.

1.Ideal Application Scenarios

(1)Multi – process Requirements

In manufacturing processes that involve multiple steps such as cleaning, cutting, welding, and weld seam cleaning, the 4 in 1 handheld laser welding and cleaning machine stands out. Take small – scale hardware factories as an example. When producing metal doors and windows, the process typically includes removing rust and oil stains from metal surfaces, cutting the materials to size, welding the components together, and finally cleaning the weld seams. Conventionally, this requires multiple separate machines. However, our 4 in 1 machine can complete the entire production process in one go, significantly boosting productivity and streamlining operations.

(2)Space – constrained Environments

For enterprises with limited workshop space, the installation of multiple single – function machines can be a major challenge. The 4 in 1 handheld laser welding and cleaning machine, with its integrated functionality, occupies minimal floor space. This is especially beneficial for start – up electronics manufacturers. In the early stages, when factory areas are often small, using this machine allows for efficient space utilization and more rational production layout planning.

(3)Strict Cost – control Demands

The procurement, maintenance, and energy consumption of multiple single – function laser devices incur substantial costs. The 4 in 1 handheld laser welding and cleaning machine, on the other hand, requires only a single investment. It reduces the number of equipment purchases, cutting down on upfront costs. Additionally, it saves on maintenance fees and energy consumption. This makes it an ideal choice for small and medium – sized enterprises, particularly those with limited capital but diverse processing needs.

(4)Customized Production

In industries such as handicraft manufacturing and mold processing, where frequent changes in processing techniques and customized production are the norm, this machine shines. For instance, in a handicraft factory making metal ornaments, the machine can swiftly switch between cutting, welding, and cleaning functions according to design requirements. This enables the creation of diverse shapes and ensures high – quality craftsmanship, meeting the unique demands of customized products.

(5)On – site Construction and Maintenance

Thanks to its handheld and portable design, the 4 in 1 machine is highly mobile. In scenarios like construction projects or on – site maintenance of large – scale equipment, where operations need to be carried out at various locations, it can be easily transported. It can perform metal structure welding, cutting, and surface cleaning tasks right at the job site, eliminating the need to move workpieces to a fixed processing area. This greatly enhances the efficiency of construction and maintenance work.

Distinctive Advantages Compared with Other Laser Equipment

(1)Superior Function Integration

Traditional laser devices usually have only one function. For example, a laser cleaning machine is solely for cleaning, and a laser cutting machine is only for cutting. In contrast, the 4 in 1 handheld laser welding and cleaning machine combines four functions. This is equivalent to integrating multiple machines, eliminating the need for frequent equipment changes and reducing the time spent on process transitions. As a result, it significantly improves overall production efficiency.

(2)Enhanced Operational Convenience

Compared with the traditional setup of multiple machines, our 4 in 1 handheld machine offers unparalleled flexibility. Its user – friendly design requires minimal complex equipment debugging and parameter adjustments. Operators can quickly master its operation after brief training, which not only simplifies the operation process but also reduces labor costs associated with specialized training.

(3)Broader Application Range and Flexibility

Most single – function laser devices are designed for specific processes and materials, limiting their application scope. The 4 in 1 handheld laser welding and cleaning machine, however, can handle a wide range of materials, from metals to certain non – metals. It meets various processing requirements from cleaning to welding, making it suitable for both simple manufacturing tasks and complex customized production. Its adaptability across different industries and production processes gives it a significant edge in terms of application flexibility.

(4)Cost – effectiveness

Single – function laser equipment generally involves high costs in procurement, installation, and maintenance and also takes up a large amount of space. The 4 in 1 handheld laser welding and cleaning machine, through its integrated design, reduces procurement, spatial, and operational costs. Moreover, its high – efficiency performance allows enterprises to complete more production tasks in less time, thereby generating greater economic benefits.