In the field of material processing, CO₂ laser cutting machine has become an ideal choice for processing flexible and brittle materials such as acrylic, leather and fabric with its unique advantages. Its core principle is to use an infrared laser beam with a wavelength of 10.6μm to focus on the surface of the material to generate instantaneous high temperature, realize non-contact cutting, avoid physical damage from mechanical processing, and achieve micron-level precision control.

For acrylic processing, CO₂ laser cutting machine shows irreplaceable advantages. Acrylic is a transparent and brittle material. Traditional mechanical cutting is prone to edge collapse and cracks, and subsequent tedious polishing is required. During laser cutting, the high temperature causes the incision to melt and solidify instantly, forming a smooth mirror-like edge, eliminating the secondary processing step. Whether it is making display stands, lampshades or art ornaments, lasers can accurately reproduce complex patterns, and can even complete the cutting of 0.1mm fine lines, making acrylic products both functional and aesthetic.

In the field of leather processing, CO₂ laser cutting has completely changed the limitations of traditional processes. Leather, especially genuine leather, is soft and ductile. Mechanical cutting is prone to deformation due to pressure, and the edges are prone to burrs. Laser cutting perfectly solves this problem through non-contact operation. In the production of bags, shoes and clothing, lasers can quickly cut hollow patterns, special-shaped contours, and even complete the carving process simultaneously. For example, in the production of genuine leather wallets, lasers can accurately cut 0.3mm wide decorative lines on 0.5mm thick leather, and the edges of the cuts are slightly charred due to high temperature, forming a unique dark edging to enhance the texture of the product.

Cloth cutting is another major application highlight of CO₂ laser cutting machines. Whether it is natural fibers such as cotton, linen, and silk, or synthetic fabrics such as polyester and nylon, lasers can achieve non-contact cutting. When traditional blades cut cloth, the fabric is prone to dislocation due to stretching, and chemical fiber materials may also have a phenomenon of drawing. Laser cutting instantly melts the fibers, and the cuts are smooth and not off the line, which is especially suitable for processing fine fabrics such as lace and wedding dresses. In mass production, laser cutting machines combined with computer typesetting software can maximize the use of fabrics, reduce waste generation, and save 15%-20% of material costs compared to traditional cutting.

When operating a CO₂ laser cutting machine, the parameters need to be adjusted according to the material characteristics. When cutting acrylic, the power is usually set at 80-150W and the speed is 5-15mm/s to ensure a smooth cut; leather processing requires reducing the power to 30-80W and increasing the speed to 10-30mm/s to avoid excessive burning; fabric cutting can use 20-60W power and 50-100mm/s high-speed cutting to improve production efficiency. In addition, by adjusting the laser focal length and blowing pressure, the cutting effect can be further optimized – acrylic cutting requires increased blowing to remove slag, and fabric cutting requires weakening the airflow to prevent fabric shaking.

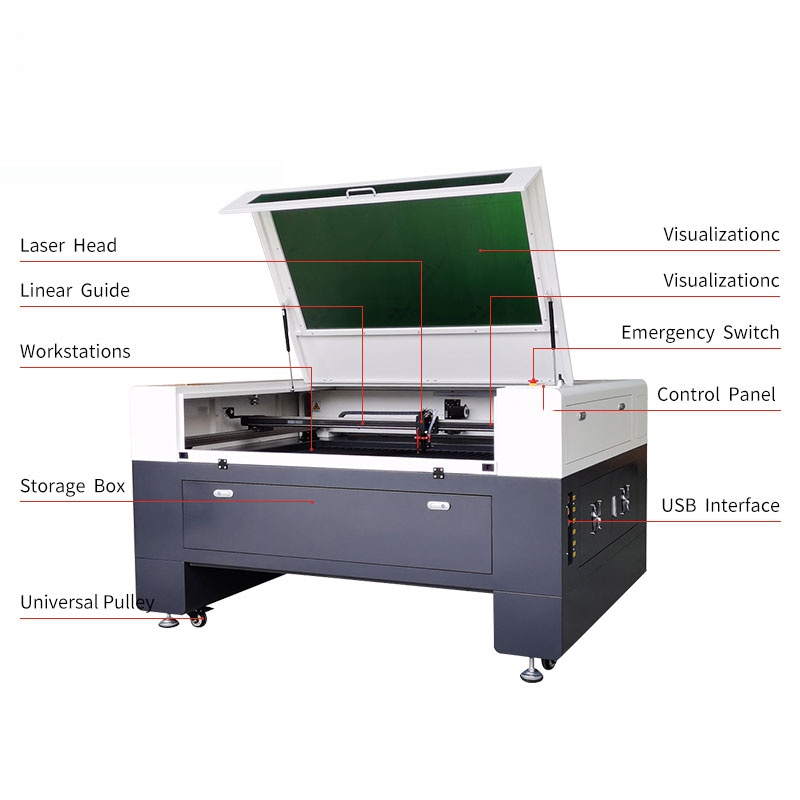

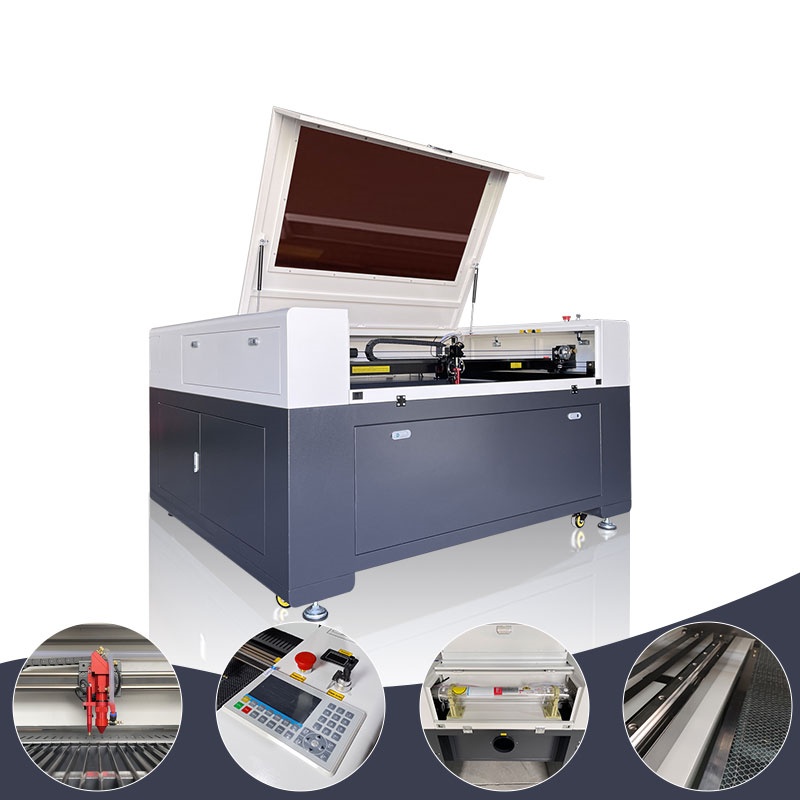

From handicraft factories to large-scale clothing companies, CO₂ laser cutting machines are reshaping the model of material processing. It not only improves production efficiency, but also expands the possibility of design, turning complex shapes from drawings into reality. With the integration of intelligent technology, modern CO₂ laser cutting machines can realize functions such as automatic feeding and CCD visual positioning, injecting more technological momentum into acrylic, leather and fabric processing, and becoming a key equipment to promote the upgrading of light industrial manufacturing.

CO₂ laser cutting machine: a precise tool for processing acrylic, leather and fabric.