The CO₂ laser marking machine, with its unique wavelength properties and non-contact processing advantages, serves as a precise “light knife” etching the mark of the times onto non-metallic surfaces like plastic, wood, and leather. This technology not only overturns the limitations of traditional ink printing and mechanical engraving, but also emerges as the core bridge between smart manufacturing and product marking, distinguished by its green, eco-friendly, and durable features. From sterile marking on pharmaceutical packaging to personalized customization of cultural creative products, the CO₂ marking machine is scripting a new chapter for laser processing in modern industrial production with its irreplaceable technical edge.

I. Core Principle

II. Technical Features

1.Ultra-high Precision

- The fundamental mode output ensures stable laser beam quality, with a minimum line width of 0.01mm, enabling clear marking even on micro workpieces and avoiding thermal deformation issues in traditional mechanical processing.

2.Extreme Speed Response

- The galvanometer system supports a scanning speed of over 10 meters per second, with single-piece processing time calculated in milliseconds, significantly improving production line efficiency.

3.Intelligent Operation

- Paired with special control software, it supports vector graphics, serial numbers, and direct database connection, enabling automated “one-click marking” processes.

4.Durable Stability

The constant current and voltage control system ensures continuous operation, with an average fault-free time exceeding 20,000 hours and low maintenance costs.

III. Industry Applications

1.Pharmaceutical Industry

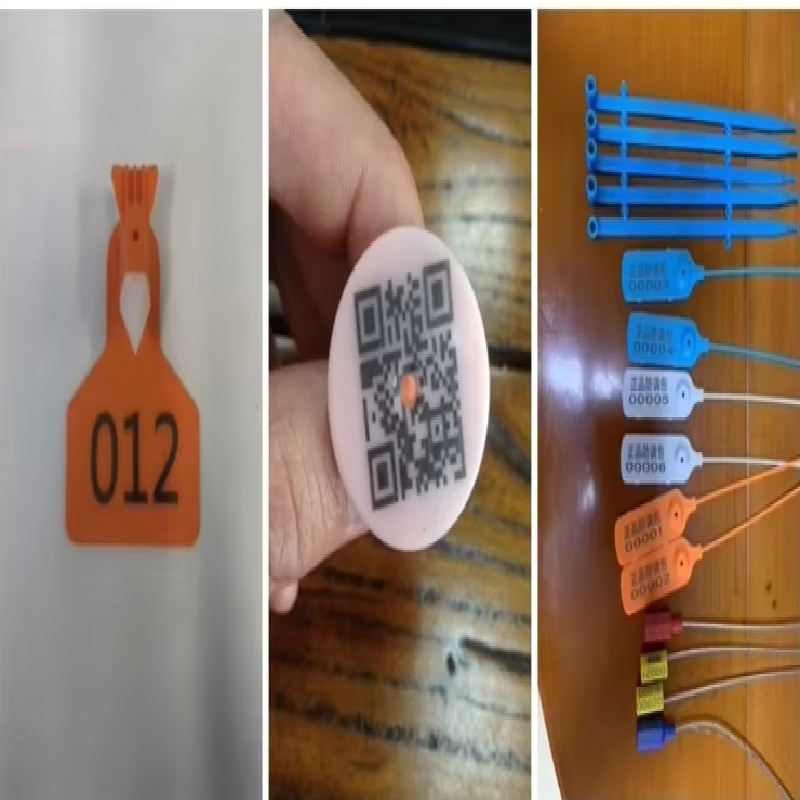

- Marking batch numbers and expiration dates on glass medicine bottles and plastic syringes, meeting medical-grade requirements for alcohol resistance and high-temperature sterilization.

2.Food Packaging

- Marking traceable QR codes on PET bottles and cartons, replacing ink printing to eliminate risks of chemical contamination.

3.Electronic Components

- Stress-free marking on plastic connectors and silicone buttons to avoid physical damage to precision parts.

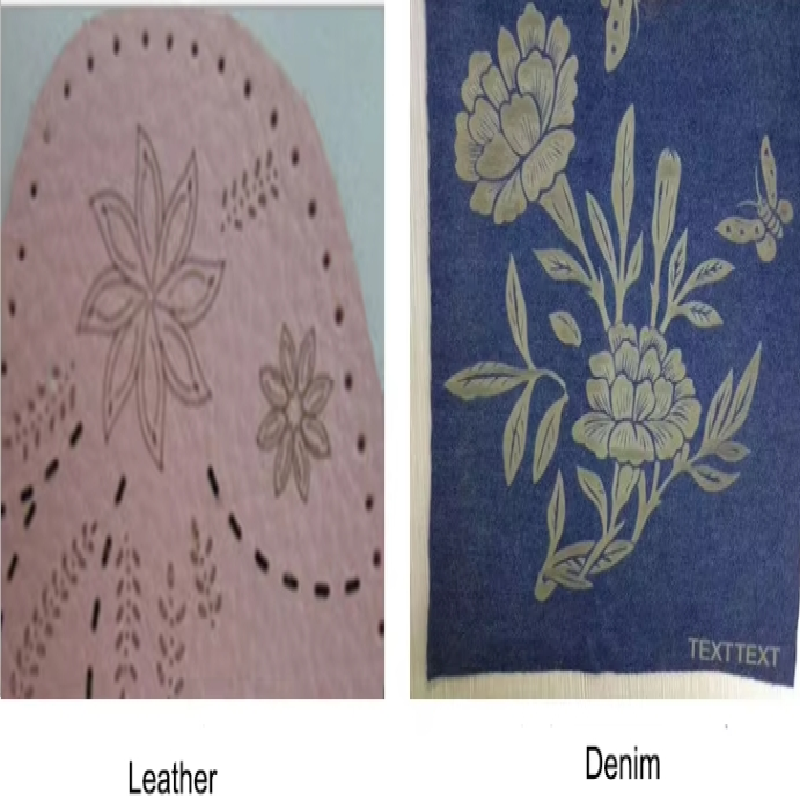

4.Craft Products

- Realizing personalized engraving on natural materials like bamboo, wood, and leather, opening up a new model for customized production of cultural and creative products.

IV. Competitive Advantages

1.Environmental Upgrade

- Eliminates ink and chemical etchants, reduces VOCs (volatile organic compounds) emissions, and complies with environmental standards like EU RoHS.

2.Cost Optimization

- No need for plate making or mold changing, supports flexible small-batch production, and reduces comprehensive energy consumption by over 40%.

3.Quality Leap

- Marks feature wear resistance and acid-base resistance, with a service life synchronized with the product itself, aiding in brand anti-counterfeiting and traceability.