In the era of industrial production moving towards intelligence and refinement, the innovation of marking technology has become a key link in improving product added value and production efficiency. With its advanced technical principles and excellent performance, the carbon dioxide marking machine has become an all-round tool in the field of industrial marking and is widely used in various manufacturing scenarios.

The carbon dioxide marking machine uses carbon dioxide gas as the core working medium, and its working principle is based on the physical process of gas discharge and laser generation. Under high voltage excitation, the discharge tube inside the equipment ionizes the carbon dioxide gas to form a plasma state. The gas molecules are excited to a high energy level under the action of the electric field. When the molecules transition from a high energy level back to a low energy level, they release an infrared laser with a wavelength of 10.64μm. After the laser beam is oscillated and amplified by the optical resonant cavity, the path is precisely controlled by the galvanometer scanning system and the focusing lens, and finally focused on the surface of the workpiece with high energy density. For different materials, the laser reacts physically or chemically with the material: on non-metallic materials such as wood and leather, the instantaneous high temperature of the laser vaporizes the surface of the material to form a clear dent; on the surface of metal materials, the laser triggers an oxidation reaction and achieves marking through color changes. The whole process is efficient and accurate.

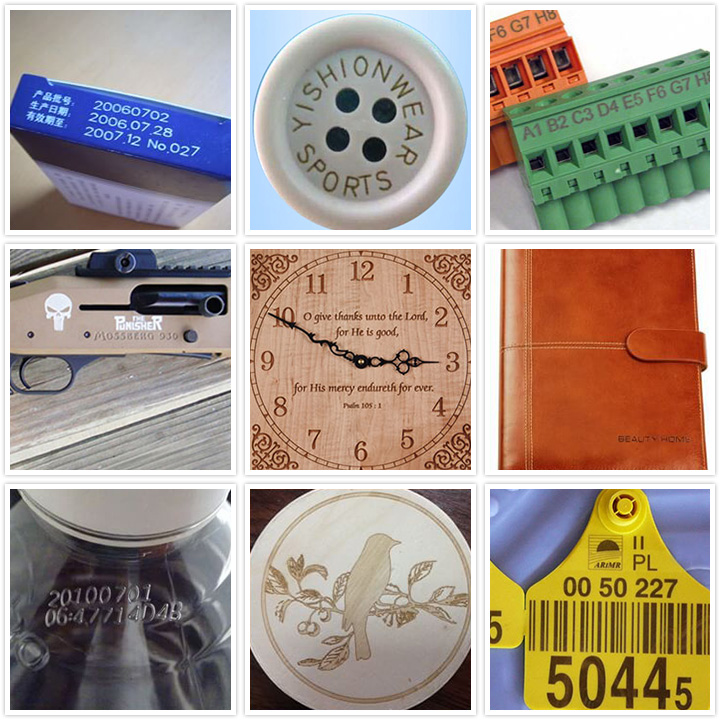

The application field of carbon dioxide marking machines is extremely wide, and they show unique value in different industries. In the packaging and printing industry, whether it is the production date on food packaging, the anti-counterfeiting mark on the drug packaging box, or the exquisite pattern on the cosmetic bottle, the carbon dioxide marking machine can quickly and clearly complete the marking, ensuring the accuracy and durability of the information and meeting the strict regulatory requirements of the industry. In the field of electronic manufacturing, its high-precision characteristics can be fully utilized, and information such as models and parameters can be marked on the surface of tiny chips and circuit board components, which not only improves the traceability of products, but also facilitates the quality control of automated production lines. In addition, in the leather and textile industry, marking machines can engrave complex and exquisite patterns to give products personalized designs; in the plastic products industry, they can mark permanent brand logos and product parameters to enhance brand recognition.

Compared with traditional marking equipment, carbon dioxide marking machines have significant performance advantages. From the perspective of precision, the spot diameter can be as small as tens of microns, which can achieve micron-level fine marking, which is difficult to achieve with traditional methods such as screen printing. In terms of production efficiency, the marking speed can reach up to several meters per minute, and it supports continuous operation, which greatly shortens the production cycle. In terms of operating costs, due to the use of non-contact processing, there is no mechanical wear, and no consumables such as ink and printing plates are required, which greatly reduces the long-term use cost. At the same time, the laser marking process does not produce harmful substances, conforms to the concept of green production, and meets the strict requirements of current environmental protection regulations. In addition, the equipment is also highly flexible, and different marking contents and patterns can be quickly switched through software programming, easily responding to diverse production needs.

In actual applications, the operation and maintenance of the carbon dioxide marking machine is also relatively convenient. The equipment is equipped with an intelligent control system, and the operator only needs to input the marking content through the computer software to complete the parameter setting and operation control. To ensure the stable operation of the equipment, the optical lens needs to be cleaned regularly to prevent dust from affecting the laser transmission efficiency; the cooling system needs to be checked to ensure that the laser working temperature is normal; and the electrical circuit needs to be routinely tested. If problems such as laser power drop and blurred marking occur, professional fault diagnosis software can be used to quickly locate the cause and perform targeted repairs.

Looking to the future, with the deep integration of laser technology, artificial intelligence, and the Internet of Things, CO2 marking machines will develop in the direction of higher precision, intelligence, and integration. On the one hand, by optimizing the optical system and control system, the resolution and speed of marking can be further improved; on the other hand, with the help of Internet of Things technology, remote monitoring and data management of equipment can be realized, providing strong support for intelligent manufacturing in the era of Industry 4.0.