In the field of material surface treatment, traditional sandblasting and laser sandblasting are two common processes, each having its own advantages and being suitable for different scenarios and requirements. Below, we will conduct an in-depth comparison of these two processes from multiple dimensions to explore the differences in aspects such as efficiency and precision.

1、Process Principles

- Traditional Sandblasting: Utilize compressed air to spray abrasives (such as quartz sand, emery, etc.) at high speed onto the surface of the workpiece. Through the impact and friction of the abrasives, remove impurities, oxide skin, etc. on the surface of the workpiece. Meanwhile, form a certain roughness on the surface to achieve purposes such as cleaning, strengthening, or decorating.

- Laser Sandblasting: Output controlled high-frequency pulsed laser through a pulse laser. Conduct the laser through an optical fiber and focus it on the surface of the processed object. Melt or vaporize the processed material instantaneously with high temperature, thus forming a rough sand surface effect on the surface of the object.

2、Equipment Composition

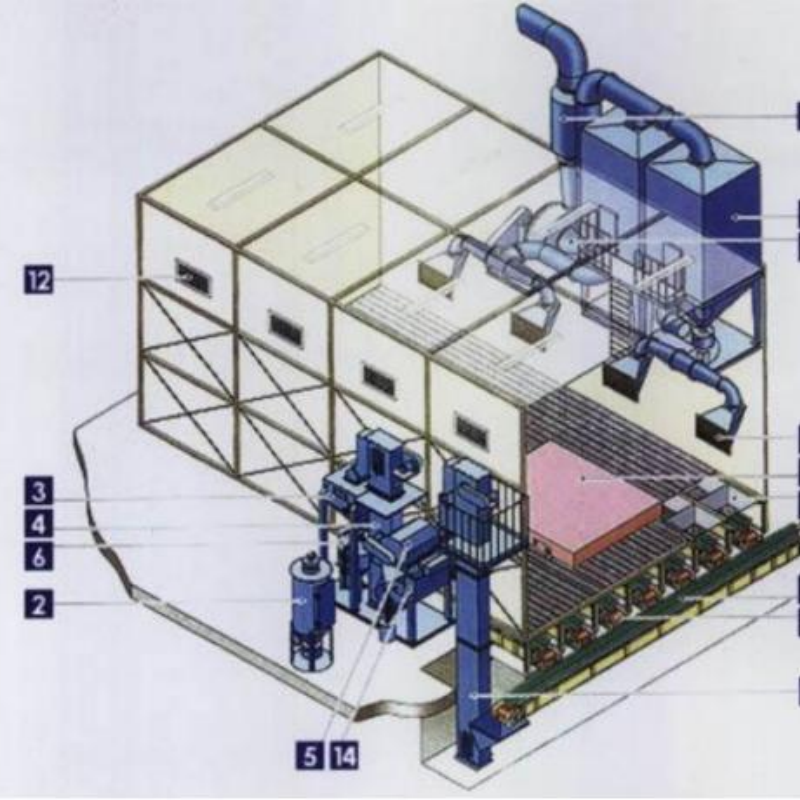

- Traditional Sandblasting: Mainly consists of a sandblasting gun, a compressed air system, an abrasive storage and conveying device, as well as a sandblasting room or a sandblasting cabinet, etc. The sandblasting gun is a key component that mixes abrasives with compressed air and sprays them onto the surface of the workpiece; the compressed air system provides power; the abrasive storage and conveying device is responsible for storing and quantitatively conveying abrasives; the sandblasting room or sandblasting cabinet is used to isolate the sandblasting process and reduce dust pollution.

- Laser Sandblasting: Mainly includes a laser, a laser power supply, a cooling system, a scanning galvanometer, a focusing lens, and a control system, etc. The laser is the core component for generating laser; the laser power supply provides energy for the laser; the cooling system is used to cool the laser to ensure its stable operation; the scanning galvanometer and focusing lens are used to control the scanning path of the laser and the size of the focused spot; the control system realizes the parameter setting and automated control of the laser sandblasting process.

3、Processing Effects

- Traditional Sandblasting: Can produce a relatively uniform rough surface, but the precision control of roughness is relatively difficult, and the consistency and repeatability of sand patterns are not as good as those of laser sandblasting. In the processing of complex shapes and fine patterns, the precision of traditional sandblasting is limited, and it is difficult to achieve high-precision detail processing.

- Laser Sandblasting: Can achieve high-precision surface treatment, precisely control the shape, size, and depth of sand patterns, and the processed patterns and characters are clear and delicate with good repeatability. According to different processing requirements, various complex graphics and texture effects can be achieved through software programming.

4、Applicable Materials

- Traditional Sandblasting: Applicable to a variety of materials, including metals, glass, stone, ceramics, etc. For materials with higher hardness, abrasives with higher hardness need to be selected to achieve better processing effects. However, for some materials that are easily deformed or have a soft texture, the impact of abrasives during the sandblasting process may cause surface damage or deformation.

- Laser Sandblasting: Can be applied to almost all materials, including metals, non-metals, semiconductors, etc. For some special materials, such as metals with high reflectivity or heat-sensitive materials, good processing effects can also be achieved by adjusting the laser parameters. Since laser sandblasting is a non-contact processing method, the requirements for the hardness and texture of materials are relatively low, and it is not easy to cause material deformation.

5、Processing Efficiency

- Traditional Sandblasting: For large-area surface treatment, the efficiency of traditional sandblasting is relatively high, and it can quickly remove large-area impurities or achieve surface roughening. But for the processing of complex shapes or fine parts, due to the limitations of the operating space and precision of the sandblasting gun, the efficiency will be significantly reduced, and more time is required for masking and protection.

- Laser Sandblasting: In the processing of complex shapes, fine patterns, or small-area regions, laser sandblasting has higher efficiency and flexibility and can quickly complete high-precision processing tasks. However, for large-area uniform sandblasting treatment, laser sandblasting needs to scan point by point or line by line, and the processing speed is relatively slow, and the efficiency is not as high as that of traditional sandblasting.

https://youtu.be/QSvNwDdbegg?si=xNgavSBoUkM78O_J

Summary: Choosing according to needs is crucial.

There are significant differences between traditional sandblasting and laser sandblasting in terms of process principles, equipment composition, processing effects, and applicable materials. The traditional sandblasting process is simple and has a lower cost, and it is suitable for surface treatment of large areas with relatively low precision requirements. On the other hand, laser sandblasting has high precision and strong flexibility, and it is more suitable for processing complex shapes, fine patterns, and special materials. In practical applications, users should comprehensively consider and select the most suitable process based on specific processing requirements, material characteristics, and cost budgets to achieve the best processing effects and economic benefits.