With accelerated urbanization and the popularization of high-end manufacturing concepts, the elevator industry is shifting from “scale expansion” to “quality improvement.” In this transformation, laser etching technology, with its precision, efficiency, and environmental friendliness, has become a core equipment support for driving the upgrading of elevator manufacturing. From core component processing to safety sign production, the diverse applications of laser etching machines are reshaping elevator manufacturing process standards and releasing significant industrial value.

Laser etching machines demonstrate irreplaceable advantages in processing core structural components of elevators, laying a solid foundation for equipment safety. Key components such as elevator shaft connectors and guide rails require extremely high dimensional accuracy. Traditional sawing and drilling processes are not only cumbersome but also prone to material loss and precision deviations. High-end laser etching equipment such as the Han’s Laser P6026D, with a processing accuracy of ±0.05mm, can precisely complete the cutting and etching of complex pipes. Its patented servo-assisted support system can adjust in real time to prevent pipe sagging. Combined with four independently controlled cylinder-driven clamps, it ensures the stability and repeatability of component positioning during processing, improving elevator safety from the source. After introducing laser equipment, an elevator component manufacturer not only simplified its production process but also significantly improved product quality stability, winning long-term cooperation from a globally renowned elevator brand.

In the field of safety marking and information traceability, laser etching machines construct a safety assurance system covering the entire lifecycle of elevators. Traditional screen printing methods easily blur information such as load markings inside the elevator car, emergency operation instructions, and production batch numbers and specifications on components, causing problems for later maintenance due to wear. Laser etching technology forms permanent marks on the surfaces of materials such as stainless steel and glass, which are not only abrasion-resistant and corrosion-resistant but also achieve micron-level precision layout. Whether it’s complex safety warning patterns or dense QR code traceability information, everything is clearly presented and never fades. This characteristic allows for precise traceability at every stage of elevator production, installation, and operation and maintenance, providing a reliable basis for fault diagnosis and safety supervision, perfectly meeting the safety management requirements of the elevator industry.

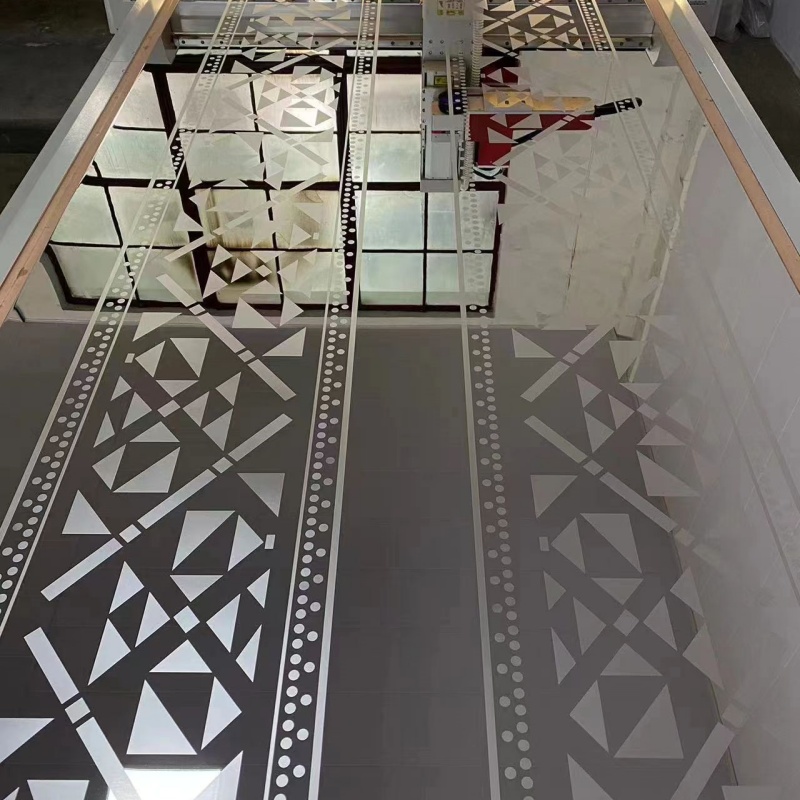

Laser etching machines have also driven innovation in elevator decoration processes, meeting the personalized demands of consumption upgrading. Modern elevators are no longer simply transportation tools, but extensions of architectural aesthetics. Laser etching technology can achieve diverse effects on elevator mirrors and stainless steel panels, precisely removing the backing film to create transparent patterns and engraving delicate textures on metal surfaces. Its material-free and easy-to-operate features support flexible customization from simple markings to complex artistic patterns, and the process is dust-free, aligning with green manufacturing principles. KL Elevator Co., Ltd. leverages laser equipment to quickly respond to personalized order demands, shortening delivery cycles while enhancing product added value with unique decorative effects. Its products are sold to over 30 countries and regions worldwide.

From an industry value perspective, laser etching machines have achieved cost reduction and efficiency improvement in elevator manufacturing through technological innovation. Compared to traditional processes, laser etching eliminates the need for mold changes, enabling flexible processing of various components and significantly reducing production costs for small-batch customization. Its integrated processing capabilities reduce process flows, increasing production efficiency by over 30% while keeping material loss rates extremely low. More importantly, the application of laser technology is driving elevator companies to shift from labor-intensive production to intelligent manufacturing. For example, one elevator component manufacturer, by introducing a complete set of laser equipment, has grown from a small workshop in southern China into a benchmark in its niche market, capturing 10% of the global market share.

In the wave of high-quality development in the elevator industry, laser etching machines, with their diverse applications in precision machining, safety assurance, and aesthetic enhancement, have become a catalyst for industrial upgrading. With the continued integration of laser technology and CNC systems, it will achieve broader application scenarios in elevator manufacturing. In the future, the deep integration of laser etching technology and the elevator industry will inevitably accelerate my country’s elevator manufacturing towards “high-end, intelligent, and green” development, providing safer, more efficient, and more aesthetically pleasing guarantees for urban transportation.