- Core Technology: Gain Medium Determines Essential Differences

The fundamental difference between the three types of lasers stems from their gain media, which directly determines their structural design and performance characteristics.

Fiber lasers use glass optical fibers doped with rare earth elements (such as erbium and ytterbium) as their core gain medium. The fiber serves as both the amplification medium and the transmission channel, making it as compact as a hair and eliminating the need for complex cooling systems. Pump light generates high power density within the fiber, achieving population inversion. Its all-solid-state structure provides strong environmental adaptability.

CO₂ lasers use a carbon dioxide gas mixture as their gain medium and generate laser light through electrical excitation. While the technology is highly mature, their structure is relatively complex and requires regular replenishment of the working gas. Their wavelength characteristics give them a natural absorption advantage for non-metallic materials, while also enabling high-power output for cutting thick plates.

Solid-state lasers use solid crystals (such as Nd:YAG ruby) as their gain medium. They rely on external optical systems for laser transmission and require specialized cooling systems to remove accumulated heat from the crystal. While they can cut highly reflective materials such as copper and aluminum, their beam quality and stability are limited.

- Performance Comparison: The Efficiency vs. Cost Tradeoff

In terms of key performance parameters, the three lasers show significant differences:

Conversion Efficiency: Fiber lasers lead the way with an electro-optical conversion efficiency of 30%-40%. CO₂ lasers are approximately 8%-15%, while solid-state lasers are only around 3%, resulting in a significant difference in energy consumption.

Maintenance Cost: Fiber lasers have virtually no consumables, with annual maintenance costs less than 5,000 yuan. CO₂ lasers require gas replacement and lens cleaning, with annual costs ranging from 15,000 to 30,000 yuan. Solid-state lasers have a xenon lamp lifespan of only 1,000 hours, resulting in the highest maintenance frequency and cost.

Power and Stability: Fiber lasers range in power from 500W to 35kW, with a diode pump lifespan exceeding 200,000 hours. CO₂ lasers can reach power up to 4kW and have moderate stability. Solid-state lasers typically have power levels below 600W and have the worst stability.

III. Application Adaptation: Materials and Requirements Determine the Choice

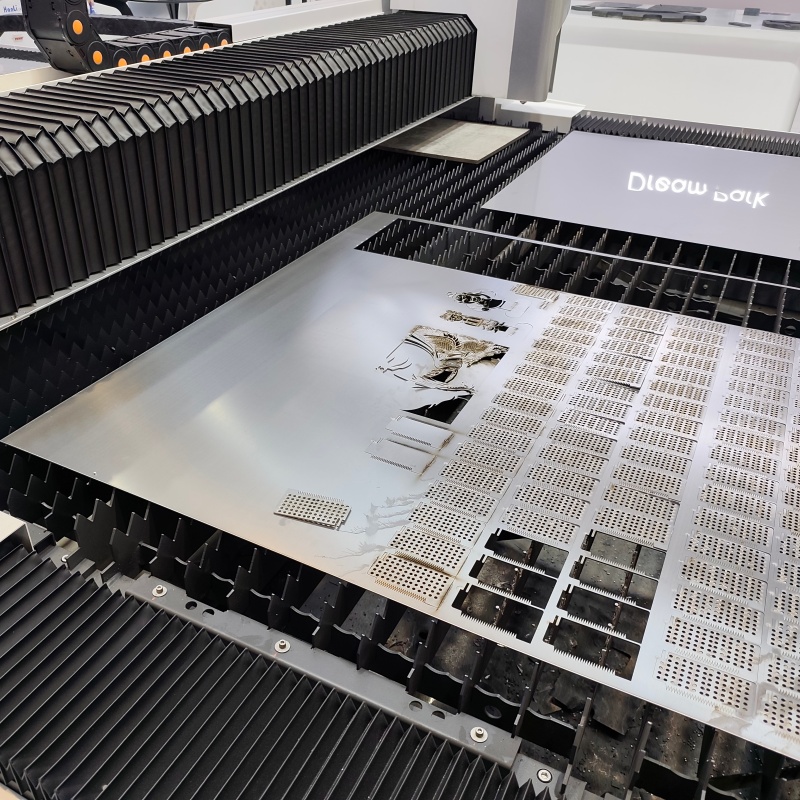

- Fiber Laser: The Mainstay of High-Precision Metal Processing

Due to its high beam quality and efficiency, fiber lasers are the preferred choice for high-end metal processing applications such as automotive and aerospace. When cutting thin stainless steel, fiber lasers offer 20% smoother cut edges than CO2 lasers. They can also adapt to flexible processing requirements and enable multi-dimensional operations. While the initial purchase cost is higher, the long-term energy and maintenance savings make them an excellent choice for mass production.

- CO2 Laser: Expert in Thick Plate and Non-metal Processing

CO2 lasers are irreplaceable in thick plate cutting and non-metal processing. They can cut stainless steel thicknesses exceeding 20mm and are widely used in heavy industries such as shipbuilding. In billboard production and furniture processing, they offer 30% higher efficiency than fiber lasers for cutting and engraving wood and plastic. Their practical applications are also favored in scientific research fields such as medical aesthetics and spectral analysis.

- Solid-State Lasers: Niche High-Reflective Material Processing

Solid-state lasers still retain their appeal in certain niche applications due to their ability to process highly reflective materials such as copper and aluminum. In small, precision drilling operations, their high-intensity lasers enable micro-aperture machining. However, due to high energy consumption and low stability, they are being gradually replaced by fiber lasers, with limited use in small, budget-constrained processing plants.

- Technology Trends: Fiber Lasers Lead Upgrades

Currently, laser technology is showing a clear trend of replacement: fiber lasers, with their efficiency and maintenance advantages, continue to squeeze the solid-state laser market. In metal processing, they are also gradually encroaching on the application space of CO₂ lasers. CO₂ lasers, on the other hand, are consolidating their advantages in non-metal and thick plate processing, creating a market landscape where fiber lasers primarily focus on precision metals, CO₂ lasers maintain their focus on thick plate non-metals, and solid-state lasers fill the gap.