Today, we’d like to introduce to you a remarkable cleaning device: the handheld laser cleaning machine.

On modern precision manufacturing production lines, the drawbacks of traditional cleaning methods are becoming increasingly prominent: Chemical agents not only pollute the environment but also damage workpieces. Physical grinding methods have difficulty reaching into complex structures and are prone to causing scratches and deformations. In contrast, the handheld laser cleaning machine makes a strong debut with its non-contact cleaning technology. With its characteristics of being non-destructive and highly precise, it has triggered an industry revolution and redefined the standards for metal surface treatment.

Relying on its unique non-contact working principle, the handheld laser cleaning machine has subverted people’s understanding of traditional cleaning. It does not need to directly contact the metal surface. Through the irradiation of a high-energy laser beam, it can instantly vaporize or peel off oil stains, dust, rust, and paint layers, which is precise and efficient. Compared with traditional cleaning methods, it not only avoids the risk of damage caused by physical contact but also gets rid of the trouble of chemical reagent residues, truly achieving the goals of green and non-destructive cleaning.

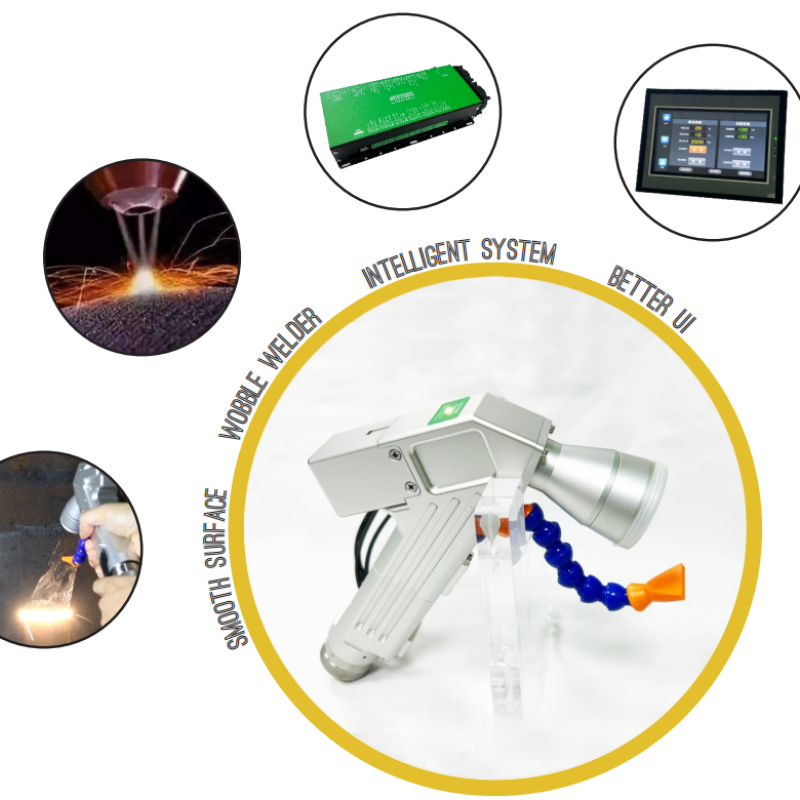

The handheld design of the equipment is truly a masterpiece of ingenuity. The lightweight and portable cleaning head, combined with the thoughtful gas protection function, greatly enhances the flexibility and safety of operation. Whether it is the surface cleaning of large metal components or the meticulous treatment of precision parts, operators can easily handle it and reach into various complex spaces and corners to complete the cleaning task. The adjustable beam width and laser frequency are like endowing the cleaning machine with a “smart brain”. According to different metal materials and surface conditions, the cleaning parameters can be flexibly adjusted to ensure that it can handle various cleaning needs with ease in many fields such as automotive manufacturing, aerospace, and mold processing.

In the automotive manufacturing industry, the surface treatment before vehicle body welding directly affects the welding quality. The handheld laser cleaning machine can quickly and accurately remove the oil stains and oxide layers on the metal surface, laying a solid foundation for the welding process and effectively improving the stability and safety of the vehicle body structure. In the aerospace field, the requirements for the cleaning precision of components are almost extremely strict. Thanks to its non-contact and non-destructive characteristics, this equipment can perfectly handle high-end metal materials such as titanium alloys and aluminum alloys, ensuring the performance and reliability of aircraft. In the mold processing stage, the handheld laser cleaning machine can efficiently remove the release agents and rust remaining on the mold surface, extending the service life of the mold and increasing production efficiency.

Technological innovation knows no bounds. During the research and development process of the handheld laser cleaning machine, it has continuously broken through technical bottlenecks, optimized energy conversion efficiency, and reduced energy consumption. Through an intelligent control system, it has simplified the operation process and enabled real-time monitoring of the cleaning effect. Its compact design and convenient mobility have even better met the urgent needs of modern manufacturing industries for efficient and flexible production. The handheld laser cleaning machine, with its innovative non-contact cleaning method and the performance advantages of flexibility and high efficiency, has redefined the standards for metal surface treatment. It is not just a cleaning device, but also a powerful driving force that promotes the green and intelligent transformation of the manufacturing industry. In the future development process of the industrial sector, the handheld laser cleaning machine is bound to unleash greater potential and lead the cleaning field to new heights.