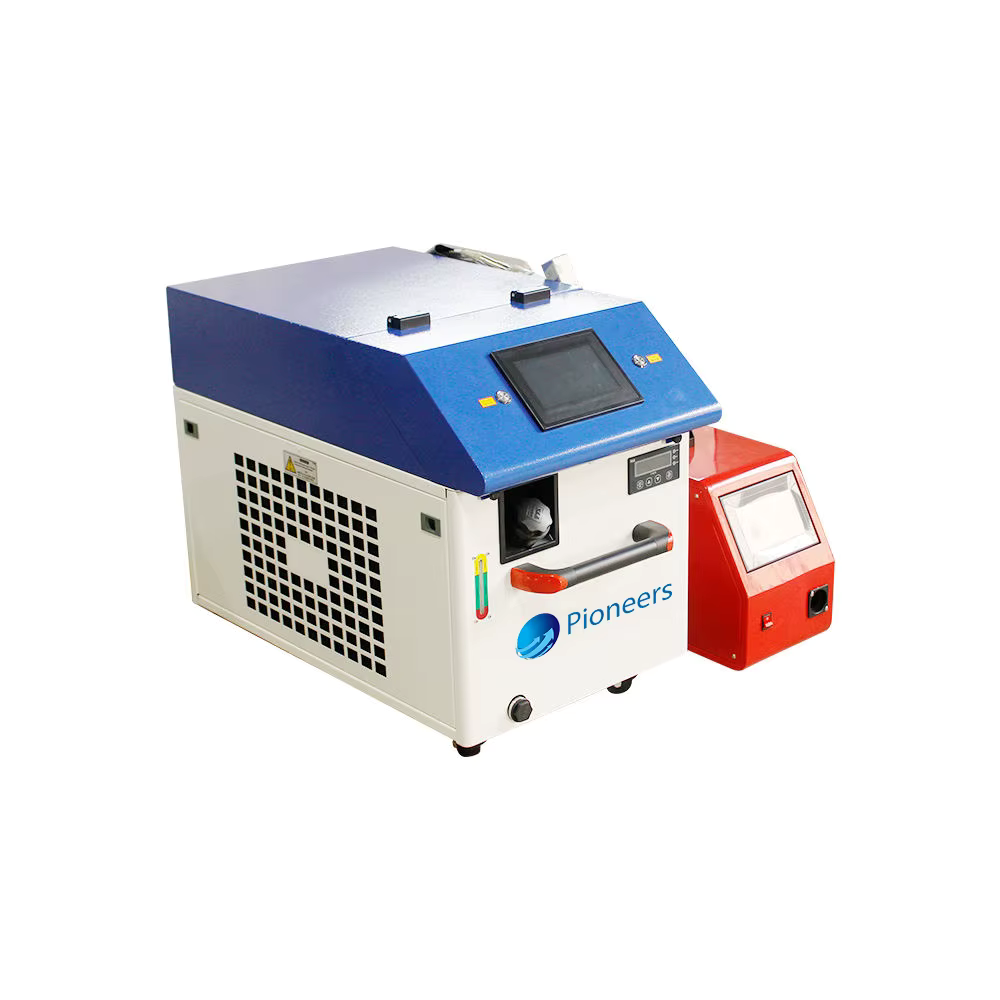

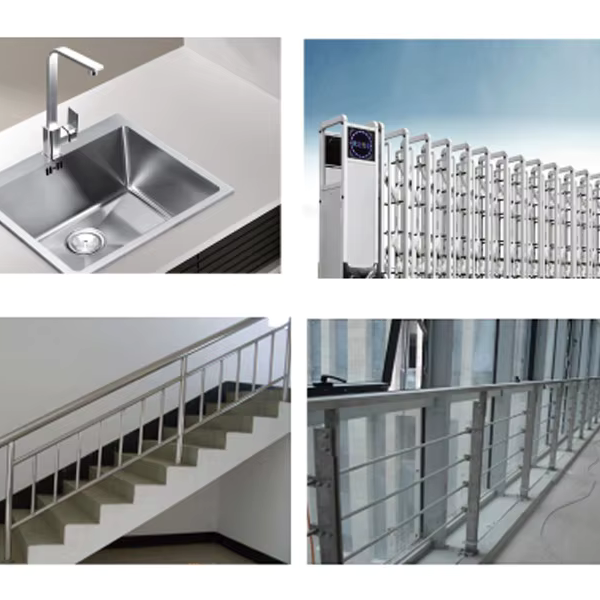

The handheld laser welding machine, with its distinct feature of “small size but great power”, has rapidly stood out in the market and become the “new favorite” in numerous industries such as mechanical processing, electronic manufacturing, and jewelry making.

In terms of the equipment’s exterior design, the handheld laser welding machine can be regarded as a “model of lightweight design”. The entire machine’s main unit weighs between 20 – 30kg, equivalent to the weight of a small suitcase. Its core operating component, the handheld welding torch, is even lighter, weighing only 1 – 2kg, which is just about the weight of two bottles of mineral water. This extremely lightweight design not only makes the equipment easy to carry but also greatly reduces the workload of the operators. In large manufacturing workshops, workers can easily transfer the equipment between different workstations to meet diverse production needs. For engineers who need to work on-site, they can even carry the welding machine like a regular tool bag to various construction sites, truly achieving the goal of “welding whenever and wherever you want”.

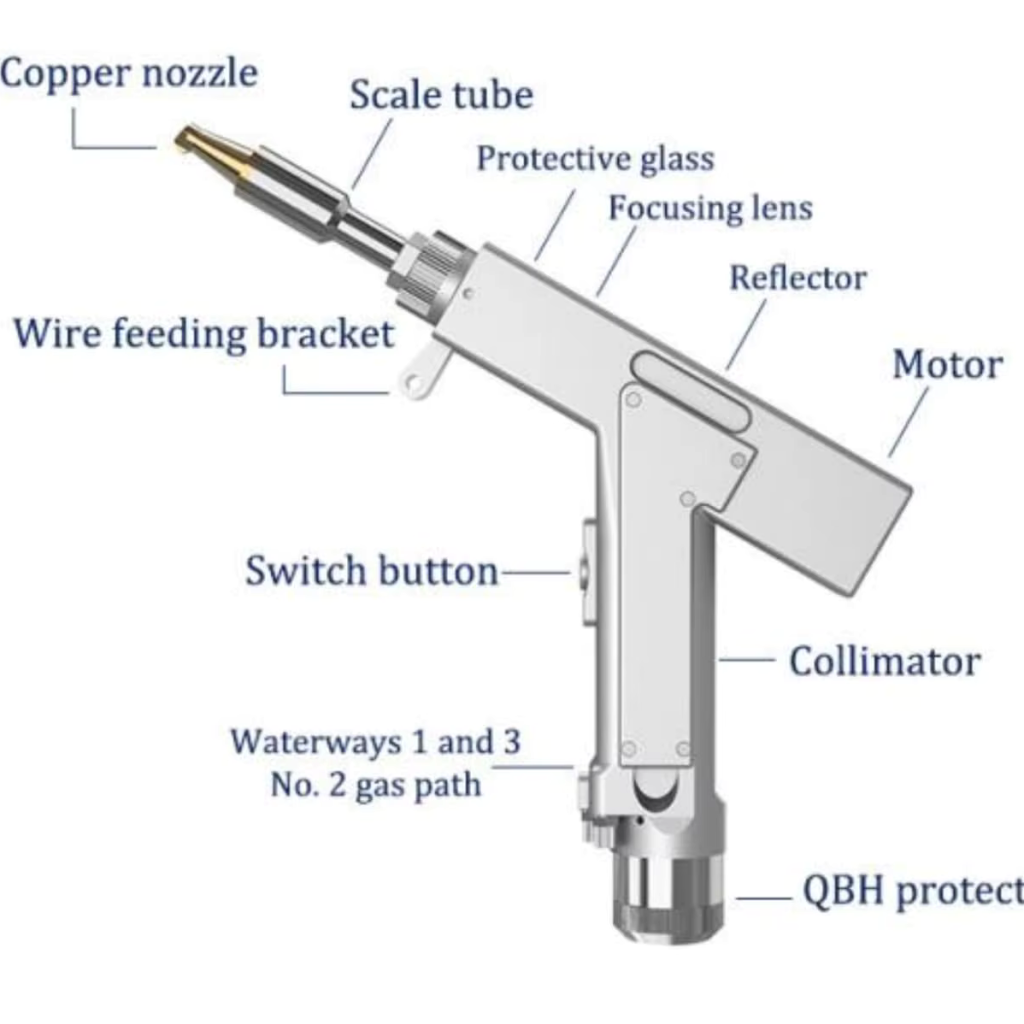

The unique design of the handheld welding torch redefines the flexibility and convenience of welding. Compared with the large body and fixed operation mode of traditional welding equipment, the handheld laser welding machine gives welders unprecedented freedom of operation. When dealing with the complex curved surfaces of automotive parts, the narrow gaps inside electronic devices, or the irregular structural components in the aerospace field, welders can freely adjust the angle of the welding torch and reach into corners that traditional equipment cannot access, achieving precise positioning for welding. This flexibility in operation not only significantly improves the welding efficiency but also makes it easy to solve high-difficulty welding tasks that were previously restricted by space. At the same time, the “plug and play” feature of the equipment further simplifies the work process. Without the need for complex installation and debugging, the equipment can quickly enter the working state just by connecting to the power supply, greatly saving the pre-processing time and significantly shortening the production cycle.

In terms of performance, the handheld laser welding machine also demonstrates powerful technical capabilities. The spot accuracy of the emitted laser beam reaches the millimeter or even micrometer level. This extreme precision enables it to accurately act on tiny welding points when welding electronic components, ensuring the stability of the circuit connection. When processing precision jewelry, it can skillfully outline delicate patterns without damaging the surrounding precious metal materials. The highly concentrated laser energy makes the welding process fast and efficient. Compared with traditional welding processes, its welding speed is increased several times. More importantly, due to the extremely small heat-affected zone of laser welding, the deformation generated during the welding process is almost negligible. This not only guarantees the appearance quality of the product but also ensures its structural strength and performance stability. High-quality welds reduce subsequent processes such as grinding and repair, effectively reducing production costs and improving production efficiency. Whether it is large-scale industrial production or personalized customized processing, the handheld laser welding machine can, with its excellent performance, provide flexible and reliable welding solutions, injecting strong impetus into the development of enterprises.