In modern industrial manufacturing, medical surgery, scientific research, and other fields, high-power lasers, with their concentrated energy and precise action, have become a key driving force for technological innovation. The core competitiveness of high-power lasers relies heavily on precise control technology. Only by achieving precise control of laser energy, beam shape, and action timing can high-power lasers be used to achieve precise targeting in complex scenarios, maximizing their effectiveness while minimizing damage to the surrounding environment.

The core of high-power laser precision control technology lies first and foremost in energy control. High-power lasers have extremely high energy density. Improper control can lead to excessive melting of materials, deformation of workpieces, and even safety accidents. The current mainstream energy control method uses a combination of a “laser power supply” and an energy feedback system to achieve dynamic regulation. The laser power supply uses high-frequency pulse modulation technology to adjust the output current in real time, thereby varying the laser’s energy output intensity. Simultaneously, a photodetector in the energy feedback system continuously monitors the actual laser output energy and transmits the data to a central controller for comparison with preset energy parameters. Any deviation triggers immediate power supply adjustment, forming a closed-loop control system of “monitor-compare-correct.” For example, in automotive steel plate welding, this system can control laser energy fluctuations to within ±2%, ensuring uniform weld strength and avoiding problems such as cold welds and leaky welds caused by energy instability.

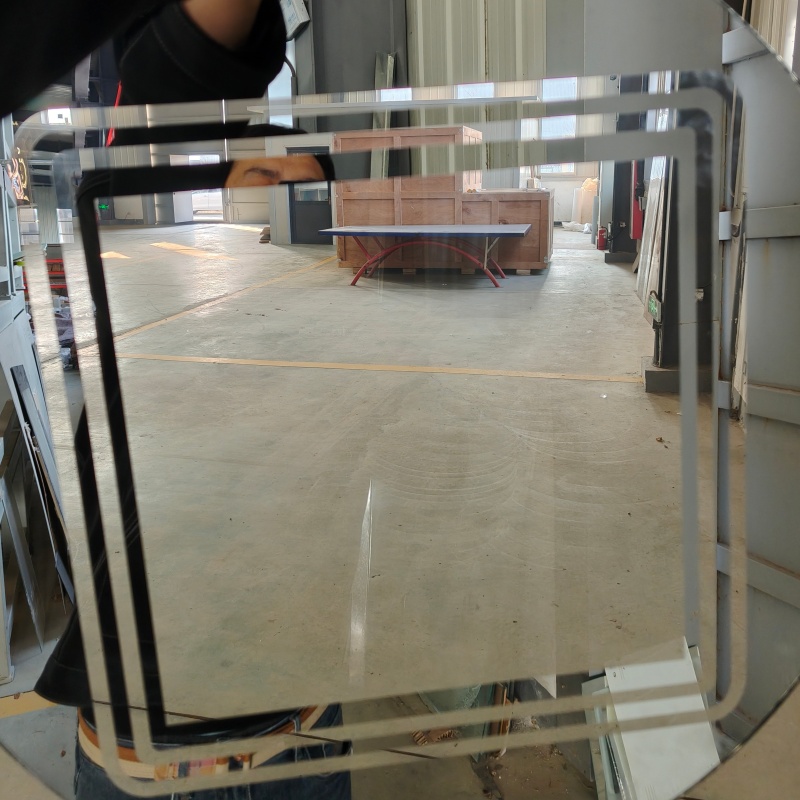

Secondly, beam shape control is another key factor in determining the accuracy of high-power lasers. The laser beam’s spot size, shape, and divergence angle directly affect its energy distribution on the surface of application. Traditional high-power lasers typically produce circular spots, making them difficult to adapt to the processing requirements of irregularly shaped workpieces. Modern precision control technology, through a combination of a “beam shaper and adaptive optics system,” enables flexible beam shape control. Beam shapers utilize microlens arrays or diffractive optical elements to transform circular beams into square, linear, or even custom-shaped beams to match different processing trajectories. Adaptive optics systems use deformable mirrors to correct wavefront distortion during beam propagation in real time. Laser beams can be distorted due to factors such as air turbulence and thermal deformation of optical components. Deformable mirrors adjust their surface shape based on data from wavefront sensors, controlling beam distortion to the nanometer level and ensuring the beam maintains the desired shape on the surface. In semiconductor chip manufacturing, this control technology enables laser spot precision to the micron level, meeting the delicate requirements of chip circuit etching.

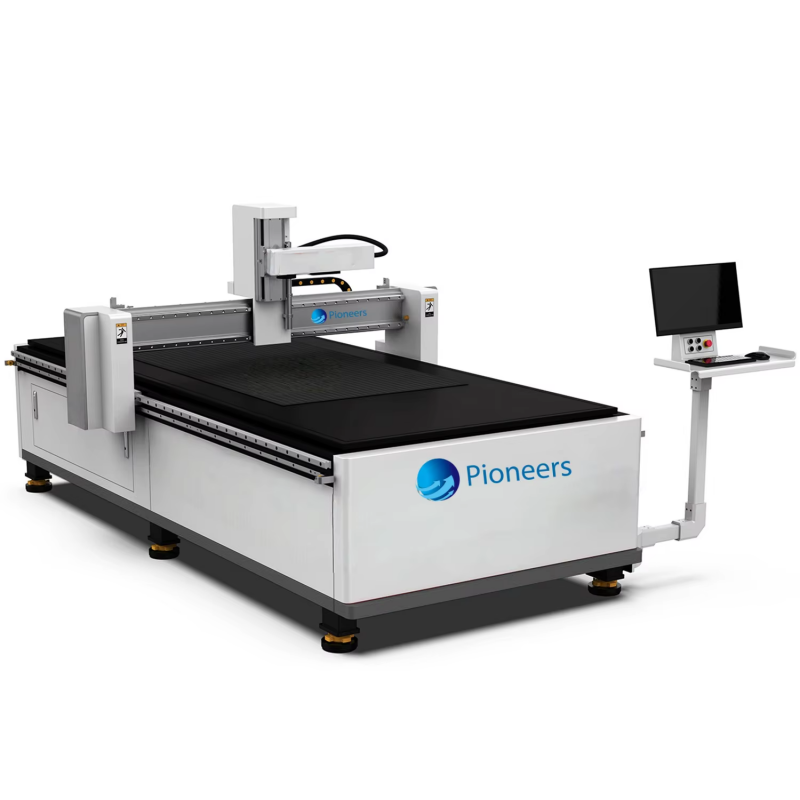

In addition, timing control is crucial in collaborative high-power laser operations. In laser cutting lines, laser on/off and energy switching must be precisely synchronized with conveyor speed and workpiece positioning. In medical laser lithotripsy, the frequency and interval of laser pulses must match the rhythm of human organ movement to avoid damaging normal tissue. Current timing control technology relies on high-precision sensors and industrial-grade PLCs (Programmable Logic Controllers). Through pre-programmed programs, it enables the coordinated linkage of multiple devices. Time synchronization accuracy can reach milliseconds or even microseconds, ensuring high-power lasers accurately time complex processes, improving operational efficiency and safety.

With the continuous advancement of technology, high-power laser precision control technology is moving towards greater intelligence and integration. The introduction of artificial intelligence algorithms enables control systems to autonomously optimize control parameters by learning from historical data. For example, in laser 3D printing, AI can automatically adjust energy output and beam shape based on the melting characteristics of different materials, minimizing printing defects. Furthermore, the integrated design of control modules with laser generators and processing equipment reduces system size, reduces signal transmission latency, and further improves control response speed.

From efficient processing in industrial production to minimally invasive treatments in the medical field to precision detection in scientific research, high-power laser precision control technology has always been the “invisible hand” behind the scenes. It not only expands the application boundaries of high-power lasers but also drives various industries towards upgrading to high precision, high efficiency, and low loss, becoming an indispensable key support for the development of modern science and technology.