For beginners who want to step into the field of laser etching, when faced with a wide variety of laser etching machines on the market, they often don’t know where to start. In fact, as long as they grasp the core key points, they can select the appropriate equipment. Now, I will explain in detail the methods for beginners to choose a laser etching machine.

Step 1:Clarify the Requirements about laser etching machine

Selection Factor | Specific Content |

Processing Materials | CO₂ laser etching machines are suitable for materials such as glass, paper, and ceramics. |

Processing Precision | Select according to the complexity and precision requirements of the elevator decoration design. If it is necessary to etch delicate classical carvings or tiny text patterns, high-precision equipment should be selected. The minimum line width can reach 0.03mm or less, and the repeatability precision is ±0.01mm. |

Processing Format | Select an etching machine with a suitable format according to the size of the elevator decoration panel to ensure that it can accommodate the materials to be processed. |

Step 2: Comprehensive Cost and Service about laser etching machine

Selection Factor | Specific Content |

Equipment Cost | The price is greatly influenced by factors such as type, brand, and performance. Equipment with high precision and a large processing format is generally more expensive. Enterprises need to evaluate the cost-effectiveness in combination with their budget and production requirements. For small enterprises or start-ups, if the processing requirements are not complex, they can choose entry-level equipment with moderate performance and a relatively low price, which can not only meet basic production needs but also avoid excessive financial pressure. |

Maintenance Cost | For CO₂ laser etching machines, components such as laser tubes have a certain service life and need to be replaced regularly. The fiber laser of fiber laser etching machines has a long service life, but it has high requirements for the cleanliness of the working environment and requires the installation of special dust removal equipment. When selecting equipment, it is necessary to understand the maintenance requirements and costs and formulate a reasonable maintenance plan. |

Brand and After-sales Service | Well-known brands usually provide more reliable product quality and performance. A complete after-sales service system can respond promptly when the equipment malfunctions, providing technical support and maintenance services to reduce downtime and production losses. Before purchasing, you can learn about the after-sales service of different brands through online reviews, industry reputation, and other channels, and choose suppliers with a good reputation. |

Amidst the numerous considerations in the selection of etching machines, we sincerely recommend the laser etching machines meticulously developed by our company. They are the ideal choices that can precisely meet your production needs.

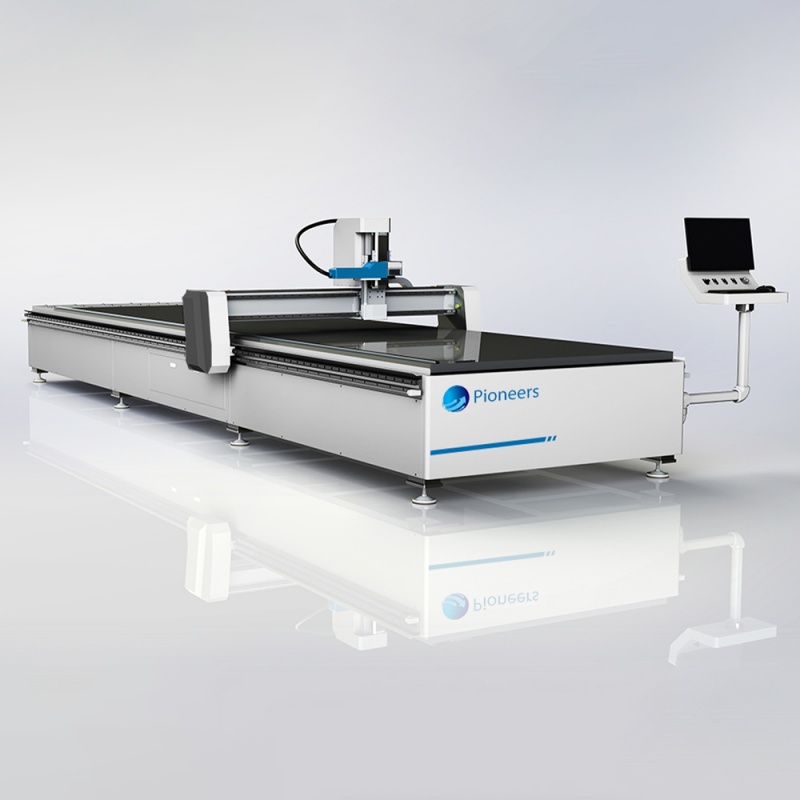

The following is a detailed introduction to our fiber laser etching machine.

The fiber laser etching machine of our company is specially designed to solve the problems of metal etching. With the advanced fiber laser technology at its core, it can achieve ultra-high-precision etching on the surfaces of various metals. The repeatability accuracy reaches ±0.02mm, enabling it to easily handle the etching tasks of complex patterns and tiny characters on metal components of elevator decorations. Moreover, the equipment has high-efficient processing capabilities. Equipped with a high-performance laser generator and an intelligent control system, it can significantly increase the etching speed.

Product Paramenters

Model No. | PLE 1325 / 1530 |

Table size(mm): | 1300*2500 / 1500*3000 |

Working way | Laser Etching |

Laser Power(W) | 100 W |

Material thickness (mm) | 0.5-80 |

Working precision (mm) | ≤0.02 |

Etching depth (mm) | 0.03-0.05 |

Etching speed (mm/s) | 10-10000 |

Files format | DXF 、PLT、BMP 、 EPS 、TIF、 |

Material fixed way: | Aluminum vacuum table |

Power of vacuum table | 7.5KW |

X Y Z travelling system | X Y Z adopt Japan Panasonic servo system |

Control System | Taiwan Syntec Follow-up laser control system |

Machine size(mm): | 3680*2800*1500 |

Machine Weight | 1200KG |

Total power: | 1KW |

Voltage | 220V/50HZ(machine)380V/50HZ( vacuum table) |

Our company has been deeply engaged in the field of laser etching machines for many years. With reliable product quality and excellent performance, we have established a good reputation within the industry. We have a professional after-sales service team that is on standby 24 hours a day, 7 days a week. Once there is a problem with your equipment, we can respond quickly, providing remote technical support or arranging for professional engineers to carry out on-site maintenance services. In addition, we also provide value-added services to our customers, such as regular equipment inspections and the formulation of maintenance plans, to ensure that the equipment is always in its best operating condition. We will safeguard your production and processing activities, allowing you to have no worries.