With the rapid development of laser technology, laser cleaning machines have emerged, bringing a revolutionary change to the surface cleaning field with their unique technical advantages.

Surface cleaning is an indispensable task in industrial production and daily life. From oil and rust on metal components to contaminants on cultural relics, traditional cleaning methods such as mechanical cleaning and chemical cleaning are widely used but suffer from drawbacks like low efficiency, heavy pollution, and substrate damage.

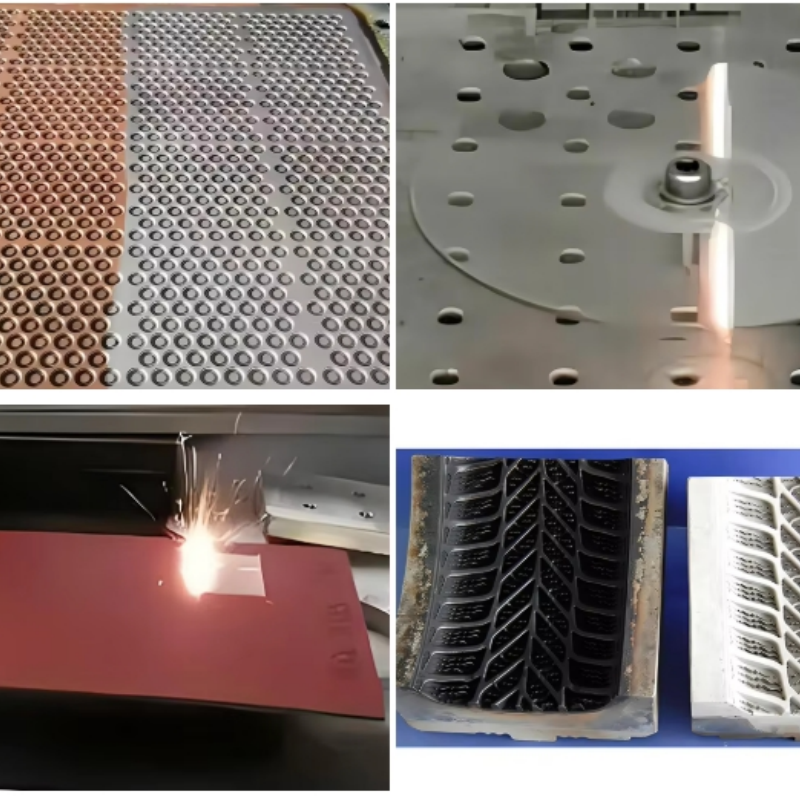

I. Working Principle of Laser Cleaning Machines

The working principle of a laser cleaning machine is based on the physical effects of laser-material interaction. When a high-energy-density laser beam irradiates the surface of the object to be cleaned, the light energy is absorbed by surface contaminants and rapidly converted into heat energy. This causes the temperature of the contaminants to rise sharply, leading to instantaneous vaporization, decomposition, or peeling. For coatings adhering to the substrate surface, laser energy can break the chemical bonds between the coating and the substrate, causing it to detach. Meanwhile, the high directivity and controllability of the laser beam enable precise control of the cleaning area and depth, avoiding damage to the substrate.

For example, in the cleaning of rust on metal surfaces, laser energy preferentially acts on the rust layer, causing it to vaporize instantly, while the metal substrate remains largely unaffected due to its low absorption of laser energy, achieving efficient and non-destructive cleaning results.

2. Successful Application Cases of Laser Cleaning Machines

Pipe Cleaning in the Energy Industry

Hua Gong Technology’s LT6060 laser cleaning machine, China’s first dedicated pipe laser cleaning equipment developed for the energy industry, can efficiently clean round pipes, square pipes, rectangular pipes, oval pipes, and special-shaped profiles at high speed and quality. For example, a 6-meter-long heavy-duty pipe with a diameter of 60mm, covered in rust and stains, can be thoroughly cleaned in less than 10 minutes using this machine. In contrast, traditional mechanical and manual grinding methods require at least 2 workers and 2 hours or more to achieve the same result.

U-Rib Plate Cleaning in Bridge Manufacturing

Hua Gong Laser’s high-power U-rib laser cleaning automated production line is applied by a leading bridge structure enterprise. When welding U-rib plates, it is necessary to remove rust, oxide scale, paint, oil, and other contaminants from the welding surfaces. Traditional grinding methods suffer from heavy labor intensity, low efficiency, unstable quality, and high dust and noise pollution. The laser cleaning line, however, achieves superior welding quality by “laser bathing” the steel surface. Its dust purification system has a maximum air intake of 10,000 cubic meters per hour, a dust capture efficiency of 99.9%, and reduces on-site noise to below 75 decibels.

Wheel Set Cleaning in Rail Transit

Zhejiang Zhongshu Laser Equipment Co., Ltd. won the bid for the “Automatic Paint and Rust Removal Station Upgrade Project for Wheel Axle Components of Guangzhou Metro Line 13,” installing a laser cleaning system for wheel axle components at the Guanhu Vehicle Base. This system uses laser technology to achieve micron-level precise stripping of paint, rust, and other deposits on wheel axles, combined with automatic AGV transportation for wheel sets, realizing fully automated upgrades of the existing production line.

Turbine Blade Cleaning in Aerospace

Shenzhen Shuidi Laser Technology Co., Ltd.’s “Intelligent Laser Cleaning Line for Aerospace Turbine Blades” stood out among numerous entries to win the “2025 Laser Golden New Application Award.” This production line efficiently and precisely cleans turbine blades, removing oil, rust, coatings, and other contaminants to meet the high standards of aerospace component cleaning. It provides strong support for the maintenance and upkeep of aircraft engines.

Carbon Deposition Cleaning in Automobile Engines

An automotive repair enterprise uses laser cleaning machines to remove carbon deposits inside engine cylinders. The laser effectively eliminates thick, hard carbon deposits on piston bottoms and intake valve surfaces, with visible results in seconds, while causing no damage to aluminum surfaces. After cleaning, engine power is restored, fuel consumption is reduced, and the engine returns to its original performance.

Laser cleaning machines are becoming the mainstream equipment in the surface cleaning field with their unique technical advantages and broad application prospects. With continuous technological innovation and improvement, they will play an important role in more industries and fields, contribute to promoting the high-quality development of various industries, and open a new era of intelligent cleaning.