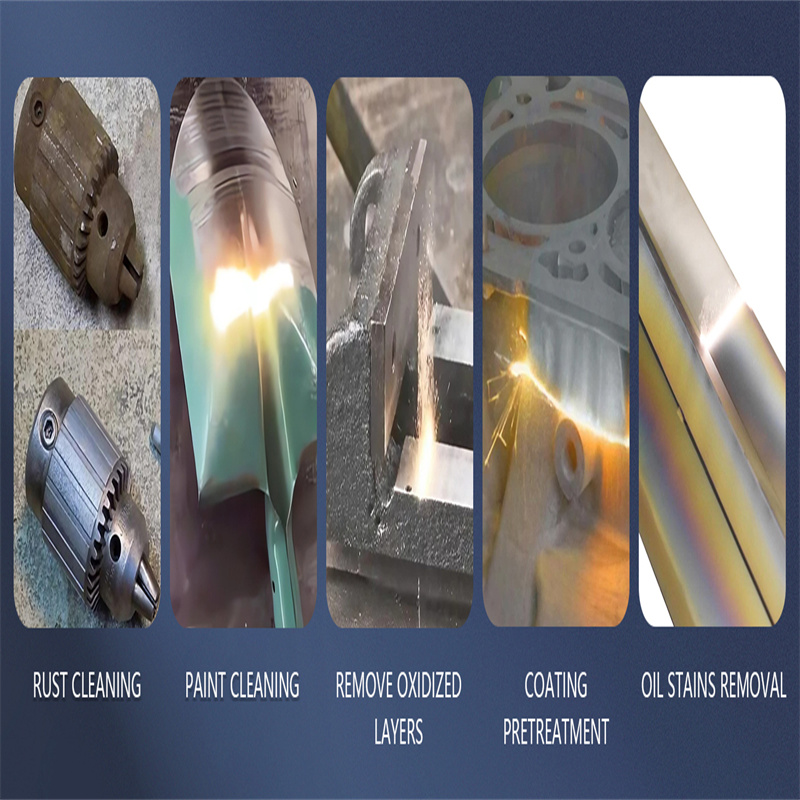

Cleaning work is ubiquitous in industrial production and daily life. From removing rust and paint from metal surfaces to the conservation and restoration of cultural relics, traditional cleaning methods often face numerous challenges. For instance, chemical reagents can pollute the environment, and mechanical cleaning may damage the surface of objects. The emergence of laser cleaning machines has provided the perfect solution to these problems. With their unique advantages, they have become a new favorite in the cleaning field.

I. The Working Principle of Laser Cleaning Machines

The core principle of laser cleaning machines is based on the interaction between lasers and matter. When a laser beam with a high energy density irradiates the surface of an object, a series of physical and chemical changes occur. For surface contaminants such as rust, paint, and oil stains, the energy of the laser is instantly absorbed by the contaminants, causing a rapid increase in temperature, leading to immediate vaporization, decomposition, or peeling. For example, when dealing with rust on a metal surface, the iron oxides are reduced under the action of the laser, and the rust layer detaches from the metal substrate. This process is extremely rapid and precise, only affecting the contaminants without damaging the substrate material of the object being cleaned.

II. The Remarkable Features of Laser Cleaning Machines

Environmentally Friendly and Pollution-Free: Unlike traditional chemical cleaning methods, laser cleaning does not require the use of large amounts of chemical reagents. The wastewater and waste residue generated after chemical cleaning often contain heavy metals and harmful substances. Improper disposal can cause serious pollution to soil and water sources. The waste generated by laser cleaning mainly consists of a small amount of solid powder, which is easy to collect and dispose of, greatly reducing the negative impact on the environment and conforming to the current concept of green development.

Non-Contact Cleaning: Traditional mechanical cleaning methods, such as grinding and sandblasting, require direct contact with the object’s surface, which may scratch or wear the surface, affecting its precision and service life. Laser cleaning works at a distance through the laser beam, eliminating the need for contact with the object’s surface and avoiding mechanical damage. It is especially suitable for cleaning precision parts with extremely high surface precision requirements, such as aircraft engine blades and electronic chips.

High Cleaning Precision: Laser beams can be focused into extremely small spots, achieving cleaning precision at the micrometer or even nanometer level. It can selectively remove specific contaminants from the object’s surface without affecting the surrounding normal materials. In the field of cultural relic restoration, it can precisely remove dirt and oxide layers from the surface of cultural relics, preserving the original appearance and historical value of the cultural relics to the greatest extent.

Efficient and Quick: Laser cleaning is extremely fast and can complete large – area cleaning in a short time. Take ship rust removal as an example. Traditional manual rust removal is inefficient and labor-intensive, while laser cleaning machines can quickly remove large areas of rust from the ship’s hull, greatly shortening the ship maintenance cycle and improving production efficiency.

Wide Range of Applications: Laser cleaning machines can clean contaminants on the surfaces of various materials, including metals, ceramics, glass, plastics, etc. Whether it is rust and paint on metal surfaces, dirt on ceramic surfaces, or fingerprints and oil stains on glass surfaces, laser cleaning machines can handle them easily, and they are widely used in many industries.

III. The Extensive Application Fields of Laser Cleaning Machines

Industrial Manufacturing Field

Mold Cleaning: In the mold manufacturing of the automotive, electronics, and plastics industries, mold surfaces are prone to residues of release agents, plastic residues, and other contaminants, which affect the mold’s service life and product quality. Laser cleaning machines can quickly and thoroughly clean the mold surface, restore its smoothness, improve the mold’s production efficiency and precision, and extend the mold’s service life.

Metal Surface Treatment: During the metal processing process, oxidation layers, oil stains, and other impurities are generated on the metal surface, which affect subsequent processes such as welding and painting. Laser cleaning can effectively remove these impurities, providing a clean and high-quality metal surface for subsequent processes and enhancing the overall product quality.

Cultural Relic Protection Field

Cultural relics carry historical and cultural values, and the dirt and corrosion layers on their surfaces need to be treated with great care. Laser cleaning machines can precisely remove dirt, rust, and residual glue from the surface of cultural relics without damaging the cultural relics themselves, restoring the original appearance of cultural relics. This provides strong technical support for cultural relic protection and restoration work. For example, they have a remarkable cleaning effect on rust on bronze wares and dirt on the surfaces of ancient building stones.

Shipbuilding and Maintenance Field

Ships navigate in a marine environment for a long time, and the hull surface is easily corroded by seawater, resulting in rust. Traditional rust removal methods are inefficient and may cause certain damage to the hull. Laser cleaning machines can quickly and efficiently remove rust and old paint from the hull surface, providing a good foundation for re-painting the ship, extending the hull’s service life, and reducing ship maintenance costs.

Electronics Field

During the manufacturing process of electronic components, tiny contaminants on the surface of electronic components may affect their performance and reliability. With its high-precision cleaning ability, laser cleaning machines can remove dust, oil stains, and residual flux from the surface of electronic components, improving the yield and stability of electronic components and ensuring the quality of electronic products.

As an innovative cleaning technology, laser cleaning machines have demonstrated great application potential in many fields with their environmentally friendly, efficient, and high-precision advantages. With the continuous development and improvement of technology, they will bring more efficient and high-quality cleaning solutions to more industries, promoting the development of various industries towards a more green and intelligent direction. Whether it is the large-scale cleaning requirements of industrial production or the special requirements of fine fields such as cultural relic protection, laser cleaning machines can perform well and become an indispensable important force in the modern cleaning field.