In industrial manufacturing, laser equipment, with its high precision and high efficiency, has become a core production tool. However, its operation and maintenance costs often account for 30%-50% of the equipment’s total lifecycle cost. Due to inappropriate operation and maintenance strategies, many companies face the dilemma of “expensive repairs, frequent consumable replacements, and significant downtime losses.” In reality, reducing laser equipment operation and maintenance costs isn’t simply about cutting investment; it’s about achieving the goal of “preventing repairs instead of rushing them, and replacing waste with precision” through scientific management, technological optimization, and process upgrades. The following are practical cost-reduction techniques from five key perspectives.

- Establish a preventive maintenance system to reduce downtime costs

Downtime is a hidden cost killer in laser equipment operation and maintenance. A sudden optical path failure in a laser cutting machine at an automotive parts company caused a 48-hour production line shutdown, resulting in direct losses exceeding 200,000 yuan. In contrast, companies that implement preventive maintenance can reduce the failure rate by over 60% and reduce overall operation and maintenance costs by 25%. Establishing a preventive maintenance system requires three key priorities: First, establish precise maintenance cycles. Taking into account equipment usage frequency (such as daily processing hours), operating conditions (temperature, dust concentration), and manufacturer recommendations, differentiate between the maintenance frequency of core components (lasers, galvanometers) and consumable parts (lenses, guide rails) to avoid over- or under-maintenance. Second, introduce condition monitoring technology. By installing IoT devices such as temperature sensors and vibration detectors, key parameters such as laser power attenuation and cooling system pressure can be monitored in real time to provide early warning of potential failures. For example, if the laser head temperature rises abnormally, the system automatically prompts cleaning of the cooling channels to prevent component burnout caused by high temperatures. Third, standardize maintenance procedures and create standardized operating manuals that clearly define maintenance steps, tool usage, and quality acceptance criteria. For example, lens cleaning requires the use of specialized dust-free cloths and alcohol to avoid scratches caused by improper operation, which increases replacement costs.

Second, optimize consumables management: From passive replacement to precise management and control.

The procurement and replacement costs of laser equipment consumables (such as laser tubes, focusing lenses, and assist gases) account for approximately 40% of total operation and maintenance expenses. Many companies have problems such as “replacing consumables when they reach their shelf life” and “excessive accumulation of spare consumables”, which result in capital occupation and waste. Optimizing consumable management can be done from three perspectives: First, establish a consumable usage ledger, recording each type of consumable, including installation time, usage duration, replacement reason, and number of products processed. This data allows for statistical analysis of the actual lifespan of consumables. For example, one company discovered that the actual lifespan of a certain brand of laser tube, when processing stainless steel, was 20% longer than the nominal lifespan. Based on this, the company adjusted the replacement cycle accordingly, saving 80,000 yuan in consumables costs annually. Second, implement a “demand-based procurement + safety stock” model. Based on consumable consumption rates and procurement cycles, a reasonable safety stock (for example, maintaining 3-5 laser lenses as a backup) is established to avoid inventory backlogs caused by over-purchasing. Emergency supply agreements are also signed with suppliers to ensure the availability of consumables in emergencies. Finally, explore the recycling of consumables. Some consumables (such as optical lenses and cooling water tank filters) can be restored to performance through professional cleaning and repair after minor wear. For example, one laser marking company sent a worn focusing lens to a factory for repair, which cost only one-third of a new lens, reducing consumables expenses by 50,000 yuan annually.

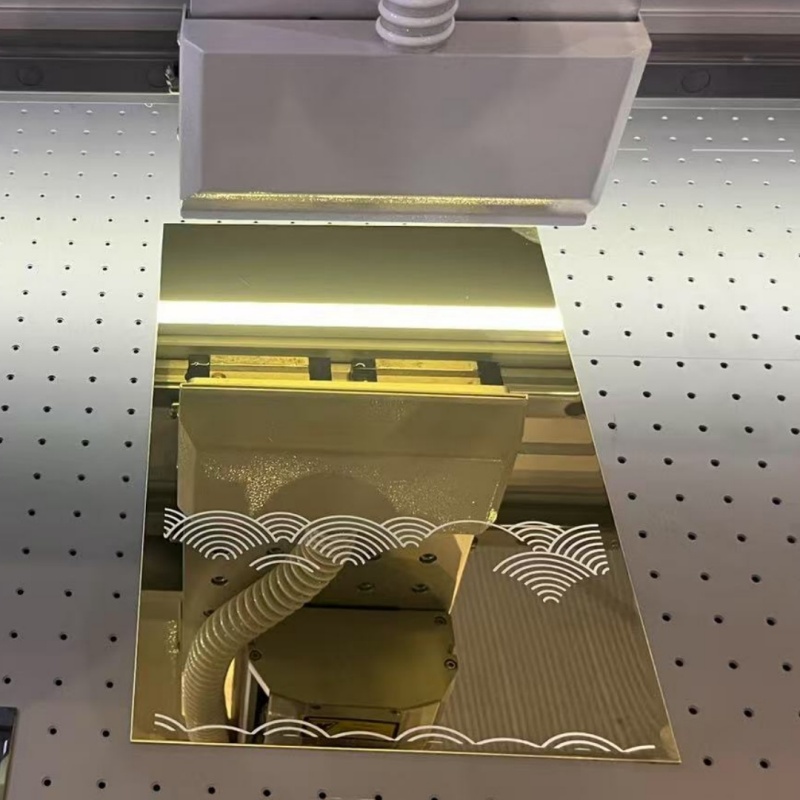

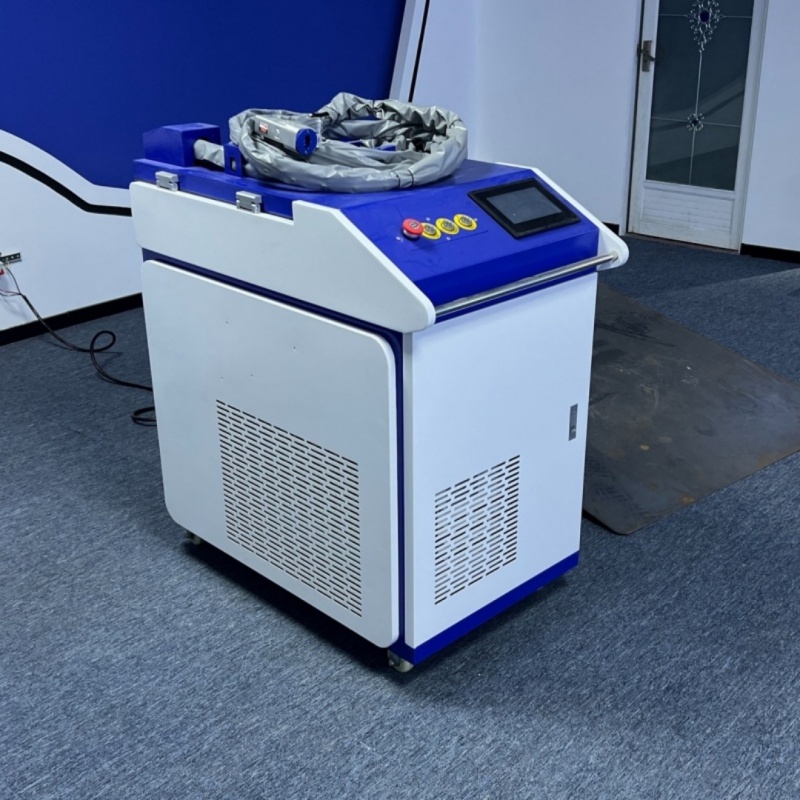

- Promote equipment technology upgrades to improve energy efficiency and stability

Old laser equipment often suffers from high energy consumption, high failure rates, and low processing efficiency, resulting in long-term maintenance costs far exceeding those of new equipment. Targeted technology upgrades can not only extend equipment lifespan but also significantly reduce operating costs. Technological upgrades can focus on three areas: First, energy efficiency optimization and upgrades. For example, upgrading traditional air-cooled laser systems to water-cooled systems improves cooling efficiency by 50%, while also reducing fan noise and energy consumption. After the upgrade, one packaging company reduced monthly electricity bills for a single laser cutting machine by 1,200 yuan. Second, core component upgrades. For equipment over five years old, higher-performance lasers can be replaced (for example, upgrading from CO₂ lasers to fiber lasers), increasing processing speed by 30% while reducing the need for optical path adjustments and lowering maintenance costs. Third, intelligent transformation can be achieved by adding PLC control systems and data acquisition modules to equipment to enable automated optimization of processing parameters and fault diagnosis. For example, if optical path deviation occurs, the system automatically calibrates, eliminating the time and errors associated with manual debugging. After the upgrade, one electronic component company reduced equipment debugging time by 60% and increased its product qualification rate to 99.5%.

Fourth, Strengthen Operations and Maintenance Personnel Training to Reduce the Cost of Human Error

Human error is a major cause of laser equipment failure. Examples include incorrect operating parameter settings, failure to properly disconnect the power supply during maintenance, and damage to components during cleaning. These errors not only cause equipment downtime but can also lead to safety incidents. Data shows that professionally trained operations and maintenance teams can reduce the incidence of human error by 70%.

Personnel training should focus on combining theory with practice. First, regular theoretical training should be conducted on equipment principles, safe operating procedures, and fault diagnosis. Equipment manufacturer technicians should be invited to explain common troubleshooting methods, such as how to determine whether a laser requires maintenance based on laser power fluctuations. Second, practical drills should be conducted, allowing operations and maintenance personnel to practice component replacement and optical path calibration in simulated scenarios. For example, monthly laser lens replacement drills should be conducted to ensure proficiency and standardized operation. In addition, a “master-apprentice” system was established, allowing experienced maintenance personnel to mentor new employees and rapidly improve the team’s overall skills. Through systematic training, one machinery manufacturing company reduced downtime due to human error by 180 hours in a year, indirectly saving 150,000 yuan in production costs.

- Relying on data-driven management to achieve dynamic control of maintenance costs

Many companies lack detailed cost tracking for laser equipment maintenance, resulting in a lack of clarity about where money is spent and how to reduce costs. Through data-driven management, maintenance costs can be made transparent and controllable. Building a data-driven management system requires two steps. The first step is to clarify cost accounting dimensions, breaking down O&M costs into breakdown repair costs (parts replacement, labor costs), preventive maintenance costs (consumables, testing costs), and downtime costs (reduced production, order delays). Monthly cost distributions for each category are calculated to identify key cost reduction areas. For example, one company discovered that breakdown repair costs accounted for 55% of its total costs. They then increased their investment in preventive maintenance, and six months later, breakdown repair costs dropped to 30%. The second step is to leverage data analysis to optimize strategies. By comparing O&M cost data for different equipment and workshops, the causes of cost discrepancies can be identified. For example, if laser equipment maintenance costs in Workshop A were 20% higher than in Workshop B, analysis revealed a higher dust concentration in Workshop A. Consequently, air purification equipment was added to reduce component wear, gradually narrowing the cost gap.

Reducing laser equipment O&M costs is a systematic process that must be implemented throughout the entire lifecycle of equipment procurement, operation, maintenance, and upgrades. Companies don’t need to pursue sweeping reforms. Instead, they can start with easily implemented details—such as establishing a consumables inventory and conducting basic training, then gradually advancing preventive maintenance systems and technology upgrades. By continuously optimizing management strategies, accumulating operational data, and enhancing team capabilities, they can ultimately achieve a virtuous cycle of reduced operational costs, improved equipment efficiency, and increased production benefits, solidifying their cost advantage in the face of fierce market competition.