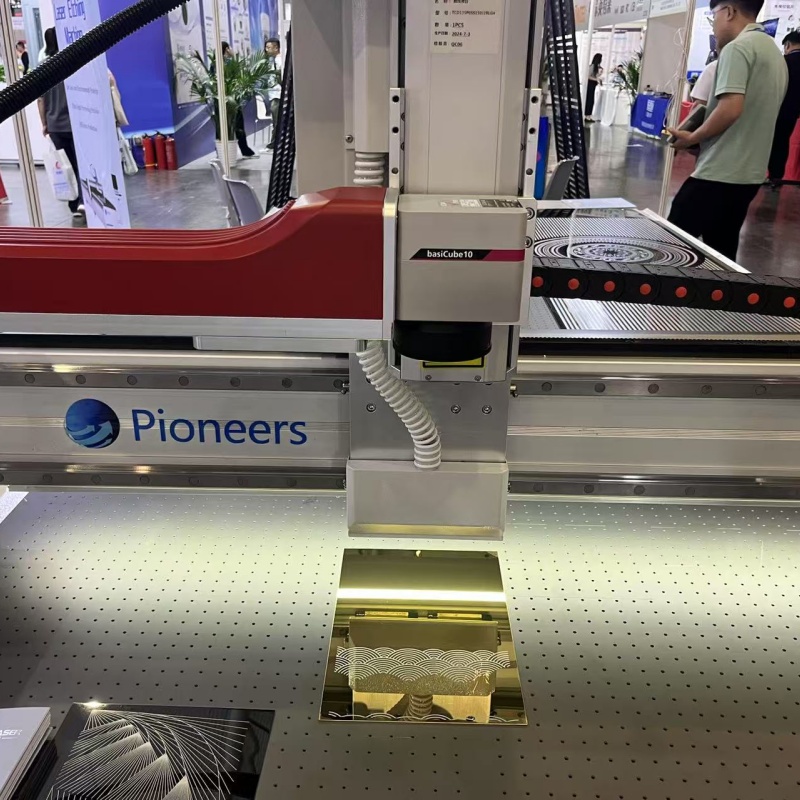

In modern manufacturing and processing, laser etching machines, with their high precision, high efficiency, and low loss, have become core equipment for surface treatment of a variety of materials, including metals, plastics, and glass. Whether it’s precision marking of electronic components, personalized engraving of handicrafts, or anti-counterfeiting marking of industrial parts, they all rely on their technical support. To fully utilize the performance of a laser etching machine, it’s necessary not only to master its operating principles but also to master key operational points.

- 1.Core Working Principles of Laser Etching Machines

The laser etching machine essentially utilizes a high-energy-density laser beam to locally irradiate the surface of a material. Through photothermal, photochemical, or photophysical effects, it removes, melts, or modifies the material, thereby forming a predetermined pattern, text, or texture. Its operating process is divided into three core steps:

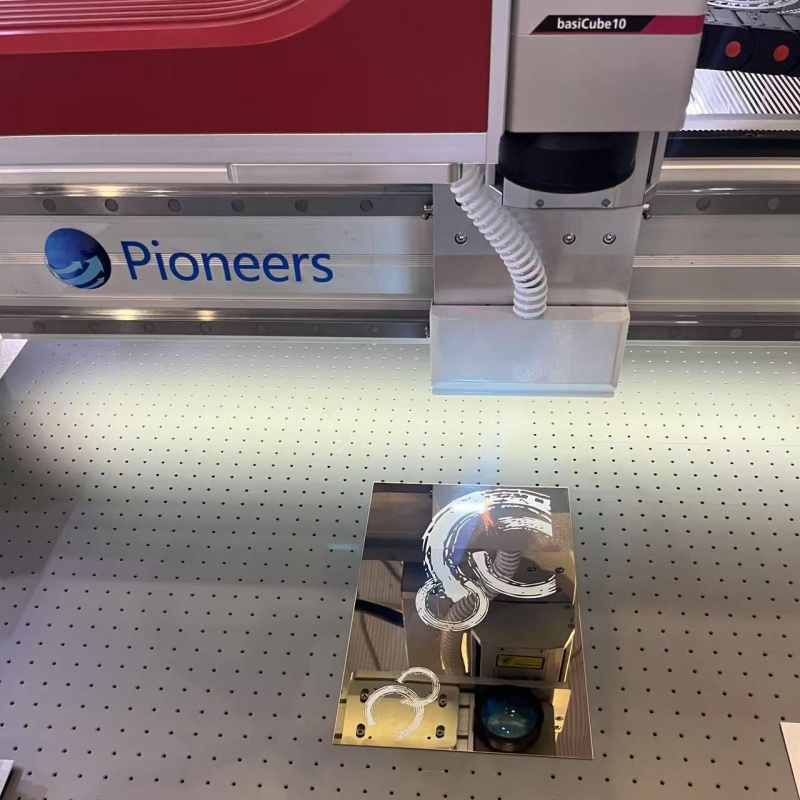

First, laser generation and transmission. The laser generator (such as a fiber laser or CO₂ laser) in the device, excited by an electric current, produces laser light of a specific wavelength (different materials are suited to different wavelengths, for example, 1064nm fiber lasers are commonly used for metals, and 10.6μm CO₂ lasers are commonly used for non-metals). The laser light is transmitted to a galvanometer system via optical components such as reflectors and beam expanders. The galvanometer system controls the deflection direction of the laser beam according to a preset program, ensuring that the etching path precisely matches the designed pattern.

The second factor is material interaction. When the laser beam is focused onto the material surface, the energy is instantly concentrated (energy density can reach 10⁶-10⁹ W/cm²), inducing physical or chemical changes in the material. For metals, the laser energy causes localized melting and vaporization of the surface, forming a concave etching mark. For non-metallic materials such as plastics and wood, the laser may remove the surface layer through thermal decomposition or vaporization. For brittle materials such as glass, the laser can achieve precise incisions by controlling thermal stress, preventing material breakage.

Finally, there is system coordinated control. The efficiency and accuracy of a laser etching machine depend on the coordinated operation of its CNC system, optical system, and motion platform. The CNC system converts the design pattern (such as a CAD file) into laser motion trajectory instructions. The galvanometer system controls the laser beam’s scanning speed and spot size, and the motion platform drives the workpiece to adjust the feed rate. Matching these three parameters (for example, too fast a scanning speed can lead to insufficient etching depth, while too small a spot size can reduce processing efficiency) is crucial to the etching effect.

- 2. Key Points in Laser Etching Machine Operation

(1).Equipment Selection: Matching Process Requirements

The first step in practical operation is to select the appropriate equipment based on the processing material, etching accuracy, and production efficiency. For example, when processing metal materials like stainless steel and aluminum alloys, fiber laser etchers (1064nm wavelength, high absorption, and clear etching results) are preferred. When processing non-metallic materials like acrylic, leather, and paper, CO₂ laser etchers (10.6μm wavelength, small heat-affected zone, preventing material burning) are more suitable. If micron-level indentations are required on hard and brittle materials like glass and sapphire (such as the fingerprint recognition area on mobile phone screens), UV laser etchers (355nm wavelength, concentrated energy, and etching accuracy up to 0.1μm) are recommended.

In addition, the power parameters of the equipment must match the processing requirements: low-power (10-30W) equipment is suitable for fine marking (such as electronic component numbering), medium-power (50-100W) equipment is suitable for etching large-scale industrial components, and high-power (100W and above) equipment is suitable for deep engraving on thick materials (such as texture processing on metal molds). Blindly selecting high-power equipment will increase energy consumption and costs, while insufficient power will lead to low processing efficiency and poor etching results. (II) Operational Procedure: Standardize Steps to Ensure Precision

(2).Workpiece Pretreatment: Clean the workpiece surface according to the material’s characteristics to remove oil, dust, or oxide layers (for example, metal workpieces can be cleaned with alcohol, while glass workpieces require a specialized cleaner). This prevents impurities from affecting etching accuracy. For curved or irregular workpieces, secure them with a dedicated fixture to ensure they do not move during processing. If the workpiece is loose, the etched pattern may shift, or even cause the laser beam to misfire, potentially damaging the equipment.

Parameter Settings: After importing the design into the CNC system, adjust key parameters based on the material and etching requirements: ① “Laser Power” (adjust according to the etching depth; for example, 5-10W is required for shallow metal engraving, and 20-30W is required for deep engraving); ② “Scanning Speed” (faster speeds result in finer etching lines and higher efficiency, but slower speeds can easily cause material overheating and deformation); ③ “Spot Size” (adjusted via a beam expander; a smaller spot size results in higher precision, but also a smaller processing area); ④ “Number of Repeats” (if a single etching depth is insufficient, multiple repeats can be set. Note the interval between each engraving to avoid localized overheating of the material). Trial Engraving and Adjustment: Before the initial machining, a trial engraving should be performed on a “test piece” of the same material as the workpiece to check the clarity, depth, and edge smoothness of the etched pattern. If “rough edges” are observed, this may indicate an excessively large laser spot or slow scanning speed. Reduce the laser spot size or increase the scanning speed. If the etching depth is uneven, check whether the laser beam is accurately focused (this can be corrected by adjusting the focusing lens height). If the material surface is scorched (common with non-metallic materials), reduce the laser power or increase the cooling air speed.

Formal Processing and Monitoring: After the trial engraving passes, formal machining can begin. During this process, monitor the equipment’s operating status in real time: observe whether the laser beam is stable (if the light spot flickers, this may indicate contamination of the optical components and requires cleaning). Observe the workpiece’s temperature and whether it is heating abnormally (the cooling system can be used to control the workpiece temperature and prevent thermal deformation). After machining is complete, turn off the laser generator and wait for the machine to cool before removing the workpiece to avoid burns.

(3).Maintenance: Extending Equipment Life

The accuracy and lifespan of a laser etching machine depend on regular, standardized maintenance. The first is optical component maintenance: reflective mirrors, focusing mirrors, etc. are easily contaminated with dust, and need to be gently wiped with a special dust-free cloth dipped in alcohol every week (do not touch the mirror with your hands to avoid fingerprint contamination). If the mirror is scratched or the coating falls off, it needs to be replaced in time, otherwise it will cause laser energy loss and affect the etching effect; the second is cooling system maintenance: the laser generator and galvanometer need to rely on water cooling or air cooling system for cooling. The water-cooling equipment needs to replace the coolant every month (to avoid scale clogging the pipes), and the air-cooling equipment needs to clean the fan filter regularly (to prevent poor heat dissipation from causing equipment overheating alarm); finally, mechanical parts maintenance: the guide rails of the motion platform need to be lubricated every month to ensure smooth workpiece feeding. The fixture needs to be checked for wear regularly, and aging parts need to be replaced in time to avoid mechanical failure affecting processing accuracy.

- 3. Industry Applications and Technology Trends

Today, laser etching machines are widely used in the electronics, automotive, medical, and creative industries. In the electronics industry, they are used for chip identification and PCB circuit etching; in the automotive industry, they are used for engine part numbering and interior texture processing; in the medical industry, they are used for anti-counterfeiting markings on surgical instruments (which can withstand high-temperature sterilization and are not easily damaged); and in the creative industry, they are used for personalized jewelry engraving and woodblock printmaking. With technological advancements, laser etching machines are moving towards higher precision (such as nanoscale etching), faster speeds (such as femtosecond laser etching, which reduces the heat-affected zone), and greater intelligence (such as AI-powered vision systems that enable automatic workpiece positioning and adaptive parameter adjustment). Their application scenarios will further expand in emerging fields (such as flexible electronics and biochips).

For operators, understanding the principles of laser etching machines is fundamental, while standardized operation and regular maintenance are crucial. Only by combining theoretical knowledge with practical experience can the equipment’s performance be fully utilized, meeting diverse processing needs while ensuring production efficiency and safety.