In the fast – paced tech era, the laser etching machine is a game – changer across industries. It’s like a “light sword”, etching permanent marks on diverse materials, offering top – notch solutions for product ID, decoration, and customization.

I. Stand – out Advantages

- Non – contact, Damage – free

Laser etching uses a non – contact approach. The laser beam, an invisible cutter, evaporates or melts materials via high – temp bursts without physical contact. This prevents wear and deformation from traditional tool – material friction, ideal for high – surface – quality products. - Ultra – Precise Etching

Achieving micron – level precision, it can etch fine lines, complex patterns, and small characters sharply. In jewelry, it carves delicate designs on gold or silver, enhancing their art value and personal touch. - Broad Material Compatibility

It works on metals, plastics, glass, ceramics, wood, leather, etc. From electronics’ shell ID to automotive part traceability, it supports product innovation across sectors. - High – speed, High – efficiency

Faster than traditional etching, it finishes tasks quickly, shortening production cycles. Its automation, via computer control, boosts efficiency and accuracy further.

II. Diverse Industry Applications

- Manufacturing

For product ID, traceability, and brand marking, laser etching is crucial. Engraving serials or barcodes helps quality control and after – sales. - Medical

Etching clear info on surgical tools, implants, etc., aids medical staff and equipment management. Personalized etching on dentures, prosthetics improves comfort. - Electronics

In electronics, it etches circuit patterns, ID, and QR codes for miniaturization. It also customizes product exteriors, adding appeal. - Art & Creative

Artists use it to etch designs on materials, creating unique art and customized gifts. It enriches cultural product packaging too. - Others

In automotive, aerospace, packaging, and home decor, it’s used for part ID, anti – counterfeiting, and surface decoration.

III. State – of – the – art Tech

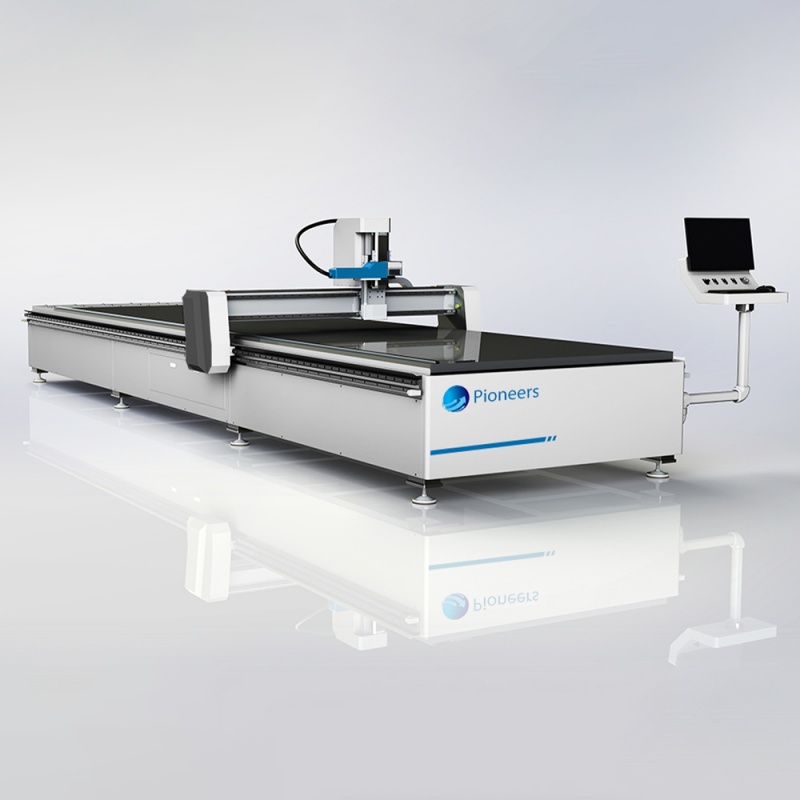

- High – power Laser

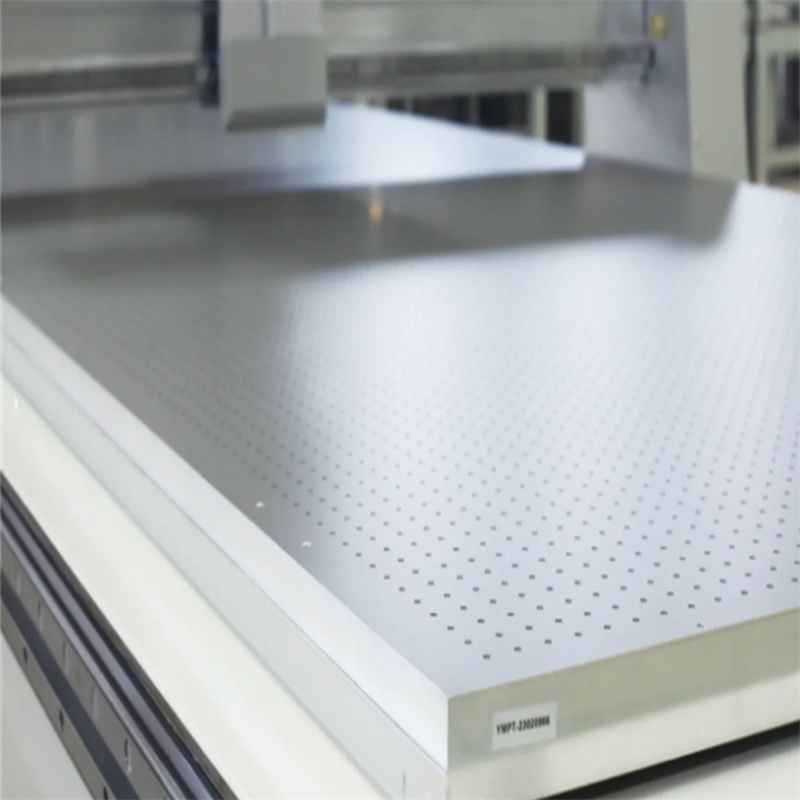

Our machine has a high – power laser source. Adjustable power ensures efficient etching on different materials. - Precise Scanning

A high – precision scanning galvo system controls the laser beam’s path accurately, meeting complex etching demands. - Smart Control

The intelligent control system features an easy – to – use interface. Software – based input enables remote and automated operation, with safety features. - Custom Solutions

Our tech team offers personalized etching solutions, from equipment function to process optimization.

Whether in manufacturing, medical, electronics, or art, our laser etching machines open new doors. Contact us now to start your journey to a more precise, efficient future.