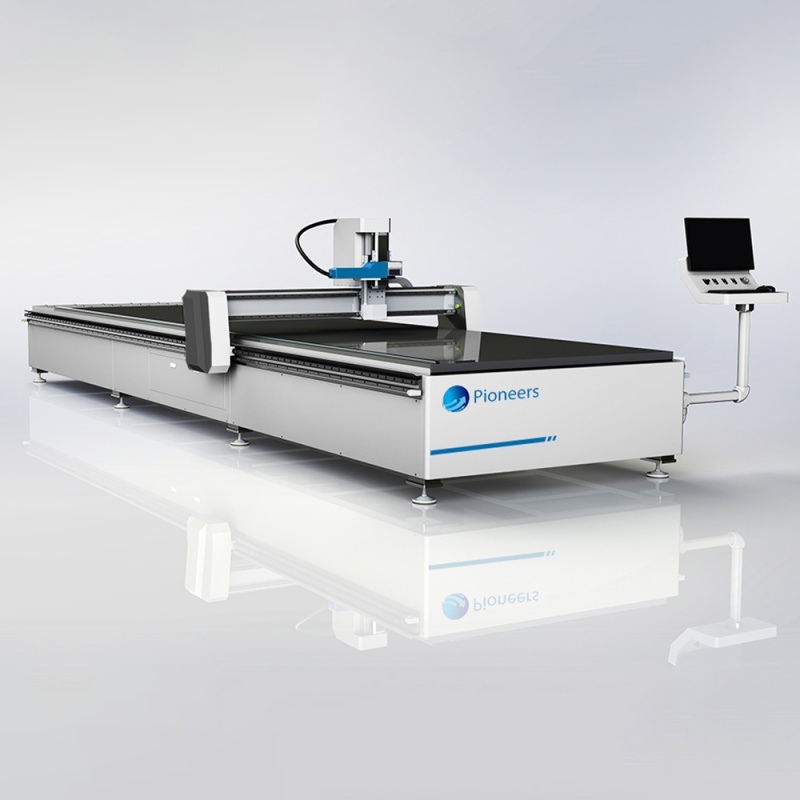

In the current era where the manufacturing industry is constantly pursuing high precision and efficiency, metal surface processing technology is of great importance. As an advanced processing equipment, the laser etching machine is bringing about a brand-new transformation to large-area engraving on metal surfaces with its unique advantages.

The laser etching machine works by using a laser beam with a high energy density to act on the metal surface, achieving the removal or modification of materials through an instantaneous thermal effect. Compared with traditional engraving processes, it does not require cutting tools, thus avoiding problems such as tool wear and replacement, and greatly improving the stability and continuity of processing. This characteristic is particularly crucial in large-area engraving on metal surfaces. During large-scale operations in traditional mechanical engraving, the frequent wear of cutting tools not only increases costs but may also lead to deviations in engraving accuracy. In contrast, the laser etching machine can always maintain stable processing accuracy.

In terms of processing efficiency, the laser etching machine has unparalleled advantages. It can quickly scan and etch the metal surface, and its processing speed is much higher than traditional methods. When dealing with large-area metal engraving tasks, it can significantly shorten the processing cycle.

The laser etching machine has broad application prospects in metal surface processing, which are mainly reflected in the following aspects:

- 1.Meeting Diverse Customization Needs

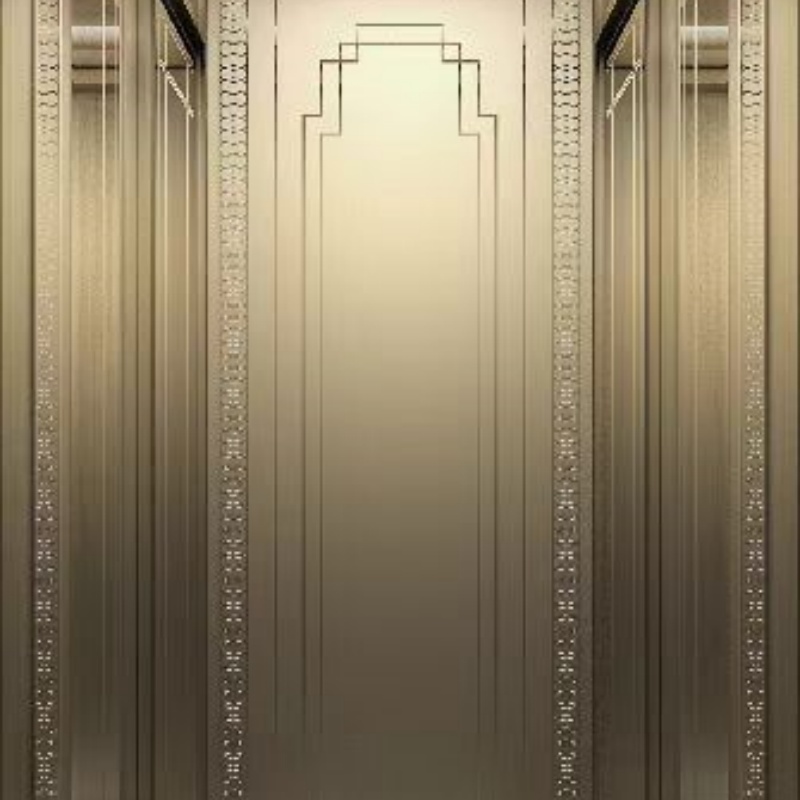

- Realization of Creativity: Various industries are constantly pursuing innovation and uniqueness. The laser etching machine can accurately present the unrestrained creativity of designers. Whether it is a complex artistic graphic or a three-dimensional text shape, it can be perfectly etched on the surface of metal and other materials, providing more possibilities for production. For example, for the personalized promotional materials of high-end brands, unique logos and patterns can be created through a laser etching machine to highlight the brand’s style.

- Customized Production: According to the needs of different customers and different scenarios, the etching patterns and contents can be quickly adjusted. For instance, exclusive promotional signs for corporate events, personalized store signs, etc., can achieve small-batch and multi-variety customized production, adapting to the flexible and changeable business characteristics of the advertising industry.

- 2.Improving Production Quality and Efficiency

- High-precision Processing: It can achieve engraving with a precision of micron level or even higher, making the lines of the signs more delicate and the patterns clearer, thus enhancing the overall visual effect. For example, the engraving of fine trademarks and the etching of tiny texts can all ensure quality, enhancing the recognition and professionalism of advertisements.

- Efficient Production: With a fast processing speed, it can significantly shorten the production cycle compared with traditional processes. It has obvious advantages when dealing with urgent orders and the production of large-scale promotional materials. For example, in large outdoor advertising projects, the laser etching machine can complete the etching work of a large number of metal plates in a short time, improving the delivery efficiency.

- 3.Enhancing Product Durability and Stability

- Wear and Corrosion Resistance: The etched patterns and texts are firmly attached to the metal surface, having good wear and corrosion resistance. Outdoor advertisements are exposed to wind, sun, rain, and other elements for a long time, and the signs etched by the laser can remain clear and complete, extending the service life of the advertisements and reducing maintenance costs.

- Adaptability to Environmental Changes: Under different environmental conditions such as temperature and humidity, the etching effect is stable, and there will be no problems such as deformation and fading due to environmental factors, ensuring the continuous and effective transmission of advertising information.

- 4.Conforming to the Development Trends of the Industry

- Intelligent Integration: With the development of various industries towards intelligence and digitization, the laser etching machine can be deeply integrated with automated production lines and digital design software to achieve seamless connection from design to production, improve the level of production intelligence, and meet the needs of large-scale and high-efficiency advertising production in the future.

- Requirements for Green and Environmental Protection: Compared with some traditional etching processes, the processing process of the laser etching machine has no chemical pollution and produces less noise, which is more in line with the current development concept of green and environmental protection in the advertising industry. In the context of increasingly strict environmental protection policies, it has stronger adaptability for development.

Looking ahead, the laser etching machine will play an even more crucial role in the field of large-area engraving on metal surfaces. With its deep integration with artificial intelligence and automation technologies, the processing process will become more intelligent and efficient.