The Future of Fabrication is Here

In an era where customization and precision are no longer luxuries but necessities, laser etching machines have emerged as the unsung heroes of modern manufacturing. From aerospace components to personalized smartphone casings, these high-tech tools are redefining how industries approach design, durability, and efficiency. As global markets demand faster turnaround times and flawless quality, laser etching technology answers the call—combining artistry with atomic-level accuracy.

- How Laser Etching Works: Science Meets Innovation

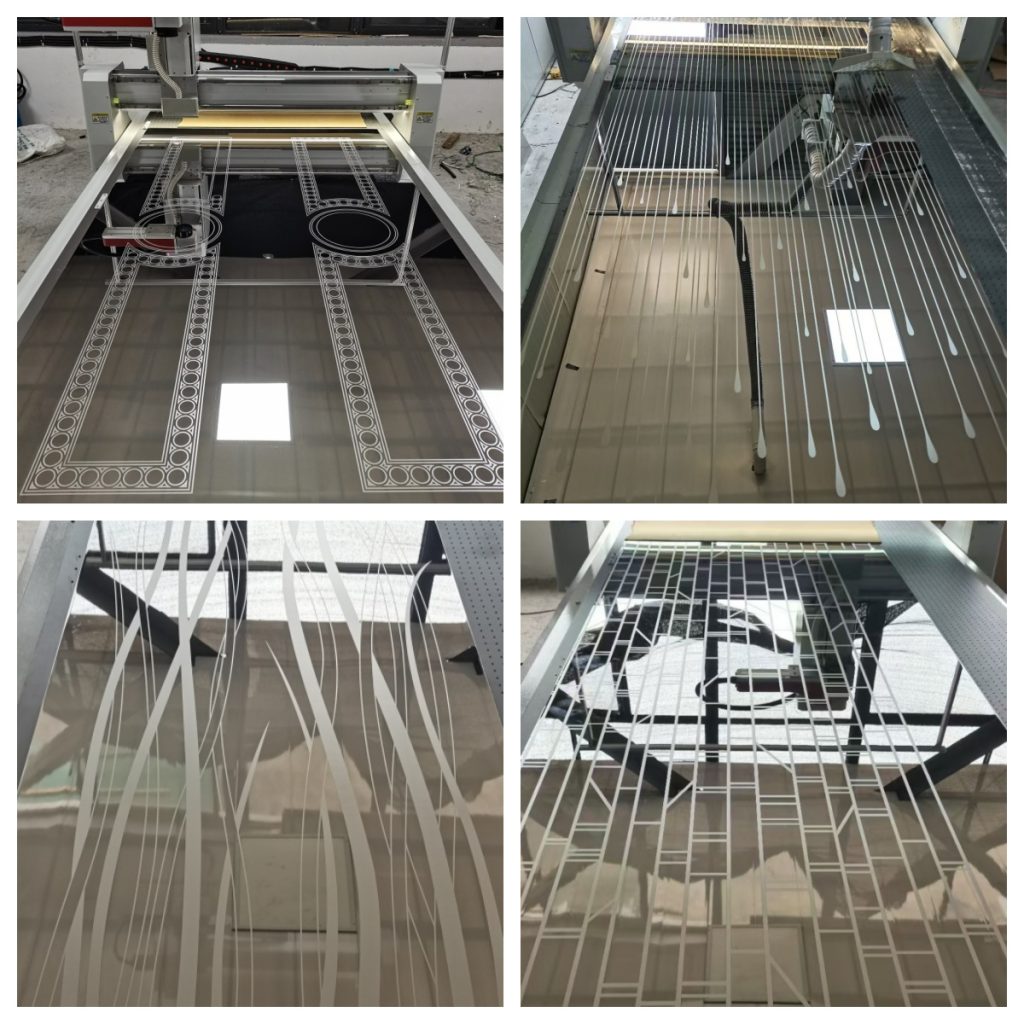

Unlike traditional mechanical engraving, laser etching utilizes concentrated light beams to vaporize material surfaces at micron-level precision. Key types include:

Fiber Lasers: Ideal for metals (stainless steel, aluminum) with speeds up to 7,000 mm/s.

CO2 Lasers: Perfect for organic materials (wood, leather, glass) and high-volume production.

UV Lasers: The go-to for heat-sensitive substrates like medical device coatings.

Advanced software integration allows operators to upload CAD designs, adjust parameters in real-time, and achieve repeatable perfection across millions of units—a game-changer for ISO-certified industries.

- Industry Applications: Where Light Transforms Business

Automotive: Permanent VIN markings that withstand extreme temperatures and corrosion.

Aerospace: Traceable part serializations meeting FAA and EU aviation safety standards.

Medical: Biocompatible instrument labeling to prevent surgical errors.

Electronics: Microscopic QR codes on microchips for anti-counterfeiting.

Retail: Bespoke luxury goods engravings that boost brand value by 40% (McKinsey 2023 report).

- Why Companies Are Switching: The ROI Breakdown

Precision: Achieve 0.001mm resolution for nanotech applications.

Speed: Etch a 10cm² design in 12 seconds vs. 8 minutes with CNC.

Eco-Friendly: Zero chemical waste; 30% lower energy use than acid etching.

Versatility: One machine handles everything from titanium alloys to biodegradable plastics.

A Boeing supplier reported a 22% reduction in part rejection rates after adopting laser systems, saving $4.7M annually.

- Choosing Your System: A Buyer’s Checklist

Material Compatibility: Match wavelength (1064nm for metals vs. 10.6µm for organics).

Power Needs: 20W for paper engraving vs. 100W+ for deep metal etching.

Software: Look for AI-powered platforms like Trotec’s JobControl® with predictive maintenance alerts.

Certifications: Ensure FDA/CE/OSHA compliance for regulated industries.

Pro Tip: Lease-to-own options from vendors like Epilog Laser let SMEs adopt tech without upfront CAPEX.

- The Next Frontier: AI and Sustainability

Emerging trends include:

Machine Learning: Systems that auto-optimize settings based on material scans.

3D Surface Etching: Create hologram-like effects for anti-tamper packaging.

Etching a Path to Competitive Advantage

As global manufacturing grows increasingly automated and eco-conscious, laser etching machines have shifted from niche tools to strategic assets. Whether you’re marking surgical tools or crafting limited-edition sneakers, this technology offers a rare trifecta: unmatched quality, operational savings, and future-ready adaptability. The question isn’t whether to invest—it’s how quickly your competitors will if you don’t.

Ready to transform your production line?