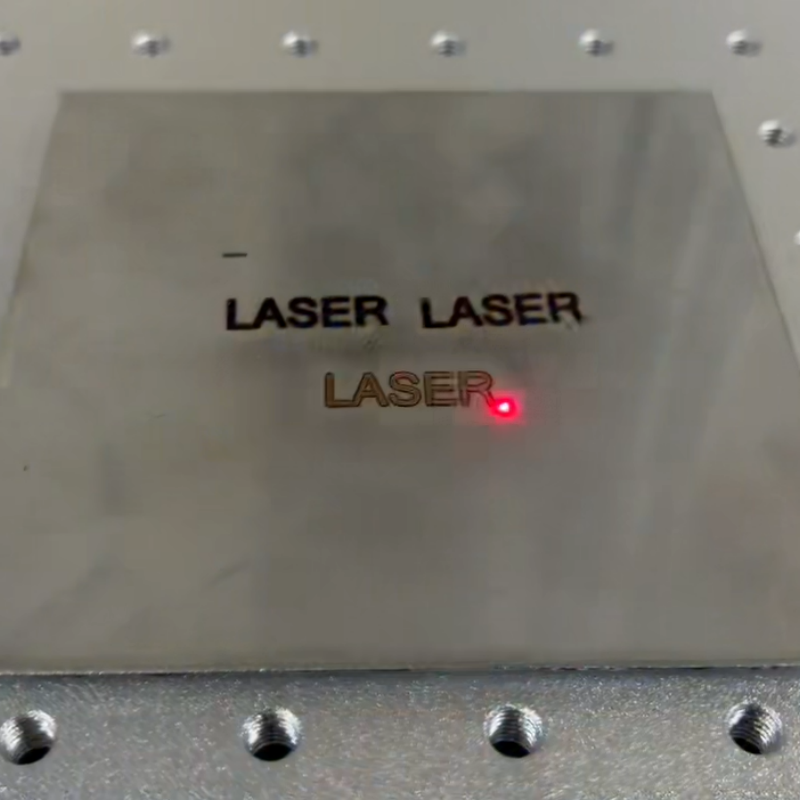

In the wave of industrial manufacturing and modern production upgrades, laser marking machines, with their core advantages of precision, efficiency, and environmental friendliness, have gradually penetrated from high-end manufacturing into various industries, becoming core equipment for product identification, traceability management, and personalized customization. Utilizing a high-energy-density laser beam to locally irradiate materials, achieving physical changes such as surface modification and vaporization, forming permanent and clear marks, not only meeting stringent production standards but also driving efficiency improvements and quality upgrades across various industries.

- In-depth Analysis of Applicable Scenarios Across All Industries

(I) Electronics and Electrical Appliances Industry: The Essential Choice for Precision Marking

Electronic and electrical products have extremely high requirements for the precision and durability of markings, and laser marking machines demonstrate irreplaceable value in this field. From tiny model markings on chips and circuit boards to brand logos and safety certification marks on mobile phone casings and chargers, to cycle markings and capacity parameters on battery casings, laser marking can achieve micron-level precision marking. Furthermore, the markings are resistant to high temperatures and abrasion, effectively resisting harsh operating environments. For example, laser marking on the battery tabs of new energy vehicles can complete clear marking within 0.1 seconds, ensuring the accuracy of battery production traceability without damaging the tab performance.

(II) Machinery Manufacturing Industry: Efficient Solution for Parts Traceability As the foundation of industrial production, the quality traceability and anti-counterfeiting management of mechanical parts are crucial. Laser marking machines can quickly mark information such as production date, batch number, serial number, and QR code on the surface of various mechanical parts such as gears, bearings, valves, and cutting tools. The marking depth can reach 0.1-1mm, effectively preventing counterfeiting and realizing full life cycle traceability. In the production of large-scale mechanical equipment, connecting parts information with the production management system through laser marking can significantly improve the informatization level of the production process and reduce errors from manual recording.

(III) Food, Beverage, and Pharmaceutical Industry: Environmental Protection for Safety and Compliance The food, beverage, and pharmaceutical industries have stringent requirements for the safety, environmental protection, and readability of markings. Laser marking machines completely solve the problems of easy peeling and environmental pollution caused by traditional ink-jet printing. In the food packaging industry, laser marking can be used to mark information such as production date, shelf life, and traceability code, ensuring no chemical residue and meeting food safety standards. In the pharmaceutical field, production dates, batch numbers, and expiration dates on medicine packaging boxes and bottles can be clearly and permanently marked using laser marking, effectively preventing the circulation of counterfeit drugs.

(IV) Building Materials and Packaging Industry: An Efficient Tool for Mass Production The building materials and packaging industry has a large production volume and fast pace, requiring extremely high efficiency and stability from marking equipment. Laser marking machines can quickly mark brand, specifications, production date, and other information on the surface of building materials such as tiles, pipes, and profiles, with a marking speed of up to dozens of characters per second, meeting the needs of mass production. In the packaging field, laser marking can achieve non-contact processing of logos, traceability codes, and anti-counterfeiting labels on the surface of cardboard boxes, plastic packaging, and glass packaging, without damaging the packaging materials, while significantly improving the aesthetics and anti-counterfeiting properties of packaging labels.

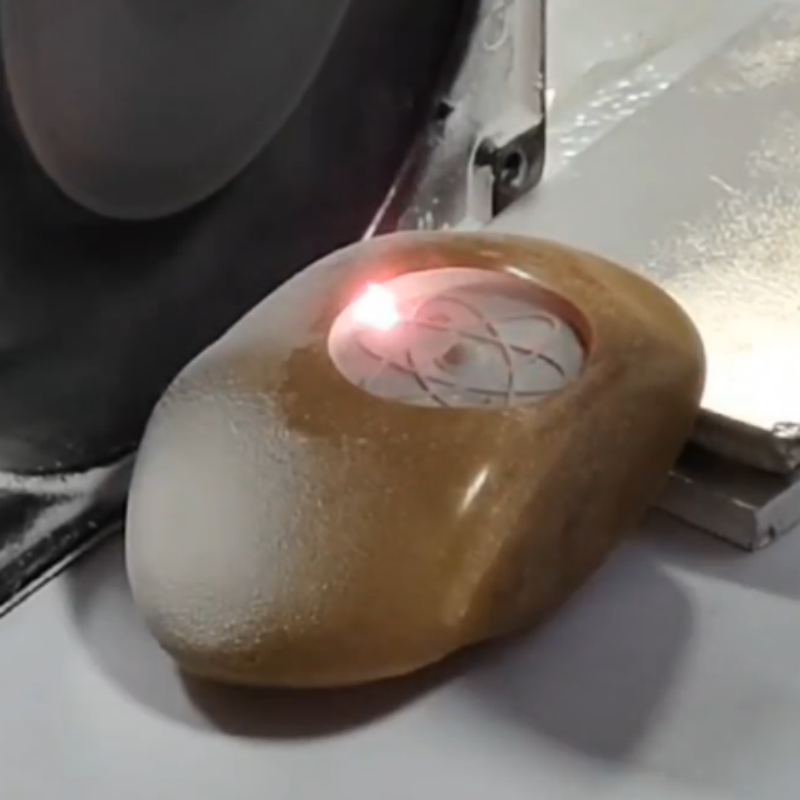

(V) Personalized Customization Field: A Flexible Tool for Creative Implementation With the upgrading of consumption, the demand for personalized customization is growing, making laser marking machines an ideal tool for realizing creative ideas. Marking personalized patterns, text, and commemorative dates on jewelry and ornaments can achieve precise and delicate marking effects, enhancing product added value. On materials such as leather, fabric, and wood, laser marking can quickly engrave personalized patterns and logos, meeting the personalized customization needs of industries such as clothing, bags, and handicrafts.

- Optimization Strategies for High-Efficiency Laser Marking Machine Applications

(I) Precise Selection: Matching Scenario Needs

Different industries and materials have different needs for laser marking machines; precise selection is a prerequisite for efficient application. For metal materials, fiber laser marking machines are preferred due to their stable output power, fast marking speed, and suitability for processing high-hardness materials. For non-metallic materials such as plastics, leather, and wood, CO2 laser marking machines can be selected, offering good wavelength adaptability and clear marking effects. For high-precision, micro-nano-level marking needs, such as chips and precision electronic components, ultraviolet laser marking machines can be selected, offering a small heat-affected zone and high marking accuracy.

(II) Parameter Optimization: Improving Marking Efficiency

Reasonable optimization of marking parameters is key to improving efficiency. Based on material characteristics and marking requirements, adjust parameters such as laser power, marking speed, and frequency: For scenarios requiring rapid batch marking, appropriately increase laser power and marking speed, while optimizing marking patterns and reducing redundant lines; for high-precision marking, reduce marking speed and increase frequency to ensure delicate marking effects. Furthermore, using an automatic focusing system reduces manual focusing time and improves debugging efficiency during material and product changes.

(III) Automation Integration: Achieving Intelligent Production Integrating laser marking machines with automated production lines is a core solution for improving overall production efficiency. By combining them with robotic arms, conveyor belts, and vision positioning systems, the entire process of automatic workpiece loading, positioning, marking, and unloading is automated, reducing manual intervention and significantly improving production efficiency. For example, on electronic component production lines, vision positioning systems can accurately identify workpiece positions, guiding the laser marking machine to complete precise marking with a positioning accuracy of ±0.01mm, while achieving a marking efficiency of thousands of pieces per hour.

(IV) Maintenance: Ensuring Stable Operation Regular maintenance is the guarantee for the long-term efficient operation of laser marking machines. Regularly clean optical lenses to prevent dust and stains from affecting laser transmission efficiency; check the operating status of core components such as the laser generator and galvanometer, and replace aging parts promptly; keep the equipment’s working environment clean and dry to avoid damage from moisture, dust, and other environmental factors. Through standardized maintenance, equipment failure rates can be effectively reduced, service life extended, and continuous and stable production ensured. Conclusion: With its wide range of applications and high efficiency, laser marking machines are becoming an indispensable key piece of equipment in modern industrial production. With the continuous innovation and upgrading of laser technology, laser marking machines will be deeply applied in more industries, injecting strong momentum into efficiency improvement, quality upgrading, and personalized development across various sectors. Enterprises only need to accurately select and optimize solutions based on their own scenarios to fully leverage the value of laser marking machines and gain a competitive advantage in the market.