The development history of laser marking machine is a struggle history of deep integration of scientific and technological innovation and industrial needs. In the 1960s, with the birth of the first ruby laser, laser technology began to show its edge. At that time, scientists were committed to exploring the application potential of lasers. It was not until the 1970s that laser marking technology began to sprout. Early laser marking machines were large in size, high in energy consumption, and could only perform simple markings on a few specific materials, but the emergence of this technology still brought new hope to the field of industrial marking.

In the 1980s, with the continuous improvement of carbon dioxide lasers and YAG lasers, the performance of laser marking machines was significantly improved. It has higher working efficiency and the range of materials that can be marked has gradually expanded. It has begun to emerge in some industries with high requirements for marking accuracy, such as electronics and precision instrument manufacturing. In the 1990s, the rapid development of computer technology and the deep integration of laser technology led to the emergence of laser marking software. Operators were able to design complex patterns and accurately control the marking process through computers, which enabled laser marking machines to truly achieve a leap from laboratory to large-scale industrial applications.

In the 21st century, the emergence of fiber lasers became an important milestone in the development of laser marking machines. Fiber lasers have the advantages of high electro-optical conversion efficiency, good beam quality, and small size, which greatly promoted the miniaturization and intelligent development of laser marking machines. Today, laser marking technology is still innovating, and new technologies such as ultraviolet laser marking and green laser marking are constantly emerging to meet the needs of different industries for high-precision and high-speed marking.

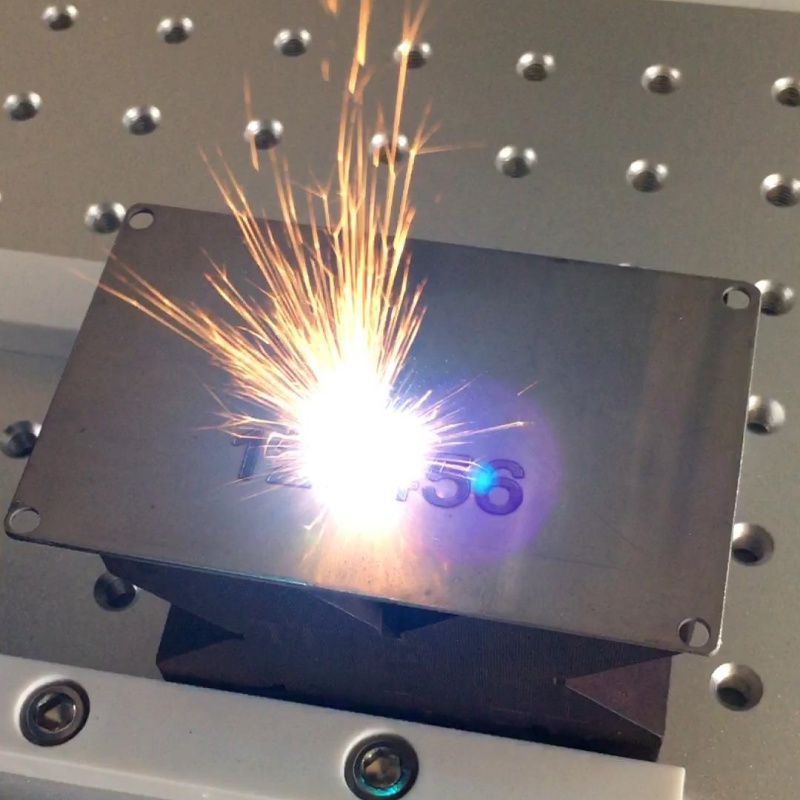

After decades of development, laser marking machines have become extremely important marking equipment in modern industry, and are playing a key role in many fields with their unique advantages and wide applicability. It uses a high-energy-density laser beam to locally irradiate the surface of the workpiece, causing the surface material to vaporize or undergo a chemical reaction that changes color, thereby leaving a permanent mark. This non-contact processing method avoids mechanical damage to the workpiece and has many advantages such as high precision, fast speed, strong permanence, and environmental protection.

To operate a laser marking machine, you need to follow a rigorous process. First, place the device on a stable workbench, connect the power cord and data cable, and carefully check whether the cooling system (water cooling or air cooling) is operating normally to ensure that the laser can be fully cooled. After completing the preparations, press the power switch to start the device and wait for the control system to complete the self-check. Most devices also need 5-10 minutes of preheating to achieve the best working state.

Then open the matching marking software, such as EzCad, CorelDraw, etc., and import or design the pattern and text to be marked. At this time, it is very important to set the marking parameters reasonably, such as laser power (generally 30%-70%), marking speed (100-2000mm/s), frequency (20-80kHz), etc., which need to be accurately adjusted according to the material type. Then, use the lifting platform to adjust the distance between the laser head and the workpiece, and fine-tune the focus through trial marking until the best clarity is obtained. Use the red light positioning function to determine the marking position, and use a fixture to fix the workpiece if necessary to ensure the marking accuracy. After everything is confirmed to be correct, click the “Start” button in the software to officially mark. It is recommended to test the effect on waste materials for the first operation. After the work is completed, turn off the laser power first, let the cooling system continue to run for 5 minutes, then cut off the main power, and regularly clean and maintain the optical lens and guide rails.

The application field of laser marking machines is extremely wide. In the electronics industry, it is used for the identification, serial number and barcode marking of circuit boards, components and consumer electronics products to help product quality traceability and management. In the automotive industry, the marking of parts such as engines and brake pads is convenient for product tracking due to the high temperature and corrosion resistance of laser marking. In the medical field, whether it is a surgical knife or an implant, laser marking ensures the durability and clarity of the mark, which meets strict quality standards. In the food and beverage industry, it marks information such as production date and batch number on the packaging without affecting the integrity of the packaging. In the jewelry and watch industry, it can be finely engraved on gold and silver jewelry, dials and cases. When customizing crafts and gifts, personalized patterns can be engraved on a variety of materials such as wood and metal. In the packaging industry, it is widely used for marking outer packaging such as cartons and plastic bags. In the aerospace industry, it provides clear and lasting identification for parts. In the mold and tool manufacturing industry, it marks tool numbers and other information for easy traceability. In the leather and textile industry, it achieves personalized design.

With its excellent performance and wide applicability, laser marking machines have become an indispensable key equipment in modern manufacturing, and continue to promote efficient development and innovative changes in various industries.