In the field of modern industrial manufacturing and marking, the fiber laser marking machine stands out with its excellent performance and has become a powerful assistant for many enterprises to improve production efficiency and product quality.

With its unique technical advantages, this advanced equipment demonstrates unparalleled value in the field of surface marking on metal and non-metal materials.

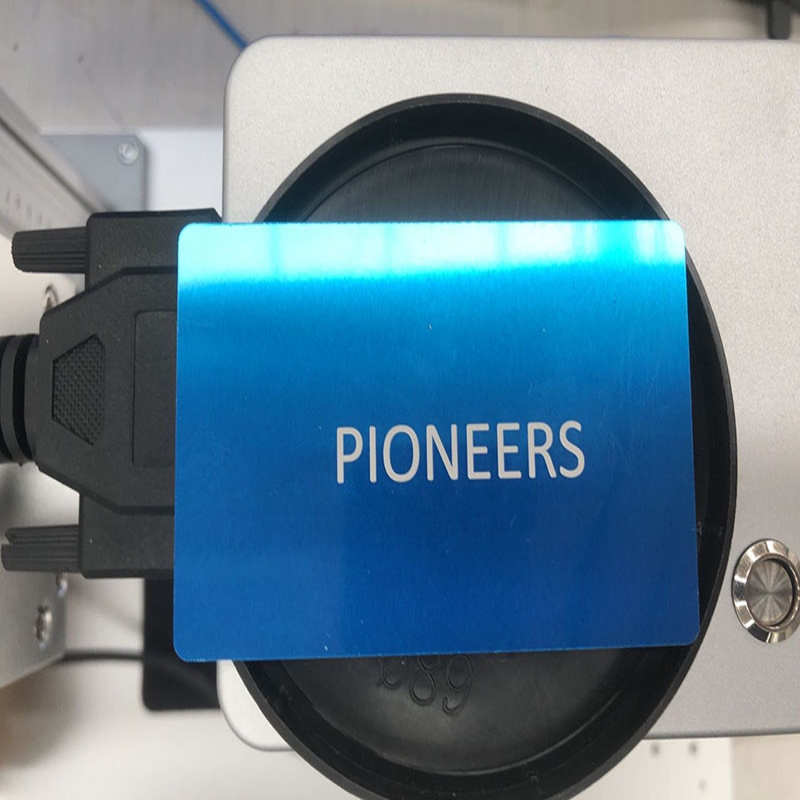

One of the most remarkable features of the fiber laser marking machine is its strong adaptability to materials. Whether it is hard metals such as stainless steel, aluminum alloy, and copper, or various non-metal materials such as plastics, leather, wood, and ceramics, they can all become the stage for it to perform its “magic”. Take the automotive manufacturing industry as an example. Various models, production dates, QR codes, and other markings on automotive parts can all be quickly and accurately engraved by the fiber laser marking machine, ensuring the clarity and durability of the markings. In the field of electronic products, the delicate logos and text markings on mobile phone casings and computer keyboards are also completed by the fiber laser marking machine. Its delicate marking effect not only enhances the aesthetic appeal of the products but also does not affect the performance and texture of the products. This wide range of material adaptability allows the fiber laser marking machine to show its prowess in multiple industries.

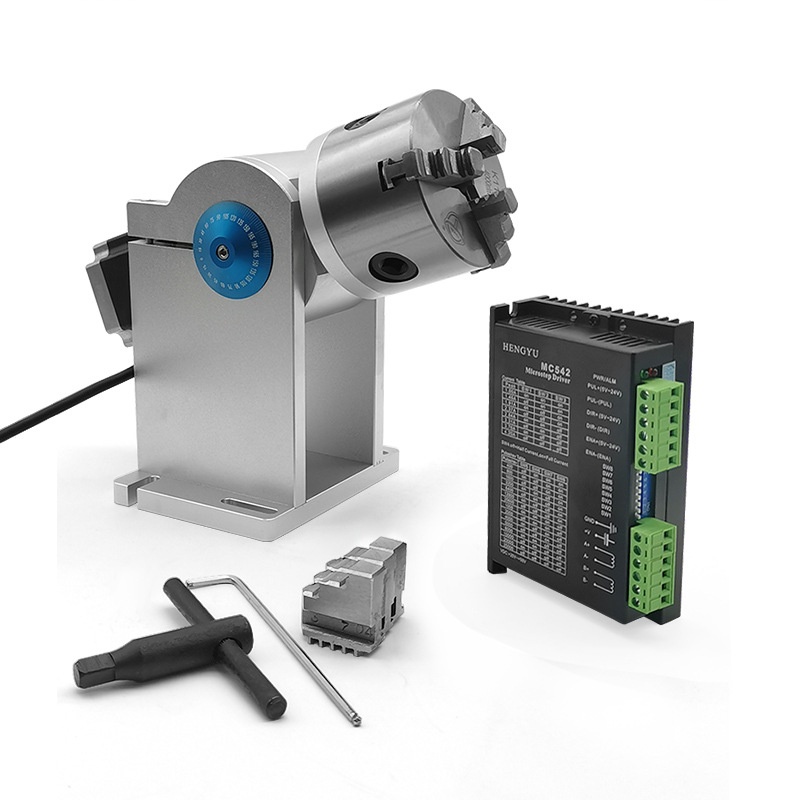

High efficiency is another highlight of the fiber laser marking machine. Compared with traditional marking methods, its marking speed is extremely fast. During the mass production process, it can significantly shorten the processing time and effectively improve production efficiency. For example, on the hardware product production line, using a fiber laser marking machine can complete the marking of a part within just a few seconds, greatly reducing the dwell time of the product in the marking process and accelerating the operation of the entire production process. At the same time, its high-precision feature ensures the accuracy and consistency of the markings. The lines are clear and the edges are neat, and even tiny characters and complex patterns can be perfectly presented. This makes the product markings not only practical but also have higher recognition and aesthetic appeal, which helps enterprises establish a good brand image.

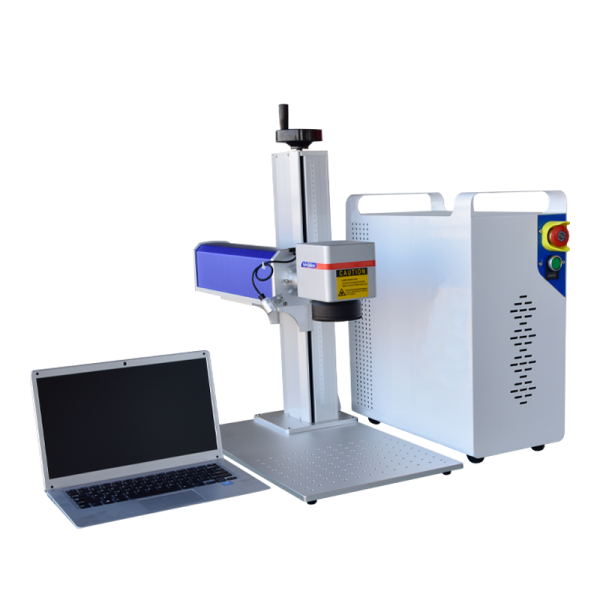

In addition to its powerful marking capabilities, the fiber laser marking machine has very simple environmental requirements. Unlike some precision equipment, it does not rely on a constant temperature and humidity environment and complex water cooling facilities to maintain its operation. Whether in an ordinary factory workshop or a production site with relatively variable environmental conditions, it can operate stably. This excellent environmental adaptability not only reduces the cost and difficulty of equipment installation and maintenance for enterprises but also makes the deployment of the equipment more flexible and convenient. Moreover, the fiber laser marking machine requires extremely few consumables, and its daily maintenance is extremely simple. The fiber laser, the core component of the machine, has a long lifespan and high stability. Under normal usage conditions, simply conducting regular and straightforward cleaning and inspections can ensure the continuous and stable operation of the equipment, further saving the operating costs for enterprises.

With the continuous advancement of technology, the functions of fiber laser marking machines are also constantly expanding and improving. The degree of intelligence and automation is increasing continuously, and the operation interface is becoming more concise and user-friendly. Even those without a professional technical background can quickly get started with simple training. In the future, with its advantages such as high efficiency, precision, and environmental friendliness, the fiber laser marking machine will play an important role in more fields, bringing more innovations and changes to industrial production and product marking, and becoming an important force in promoting the high-quality development of the manufacturing industry.