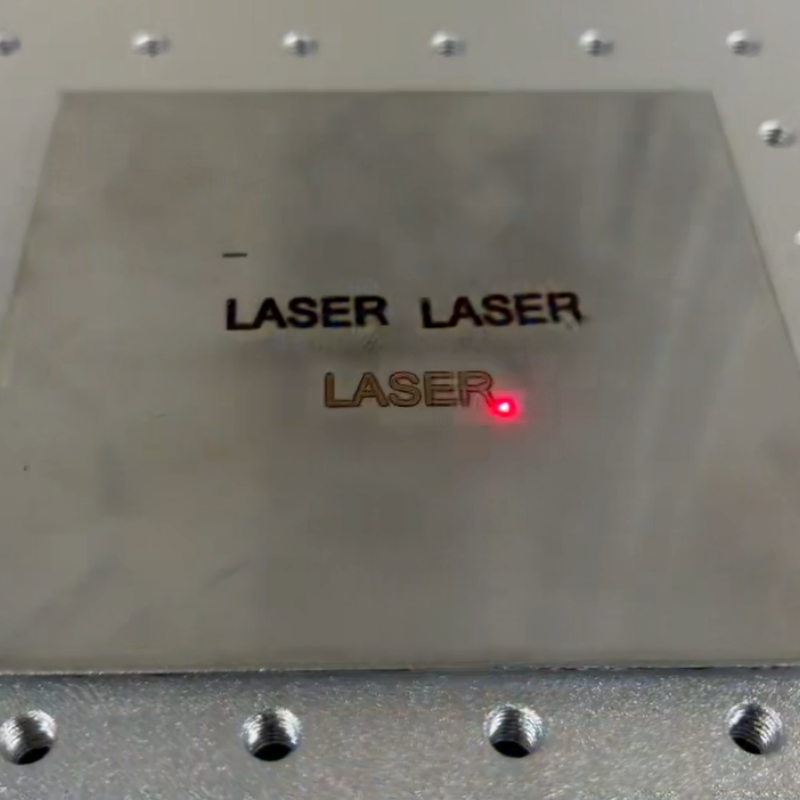

In the wave of intelligent manufacturing, standardized production can no longer meet the diverse needs of the market. Laser marking machines, with their personalized customization capabilities, are becoming a core link connecting technology and the market. From precision marking in 3C electronics to traceability marking in the food cold chain, this non-contact processing technology, with its advantages of high precision and high flexibility, is sparking a customization revolution across industries, injecting unique value into products.

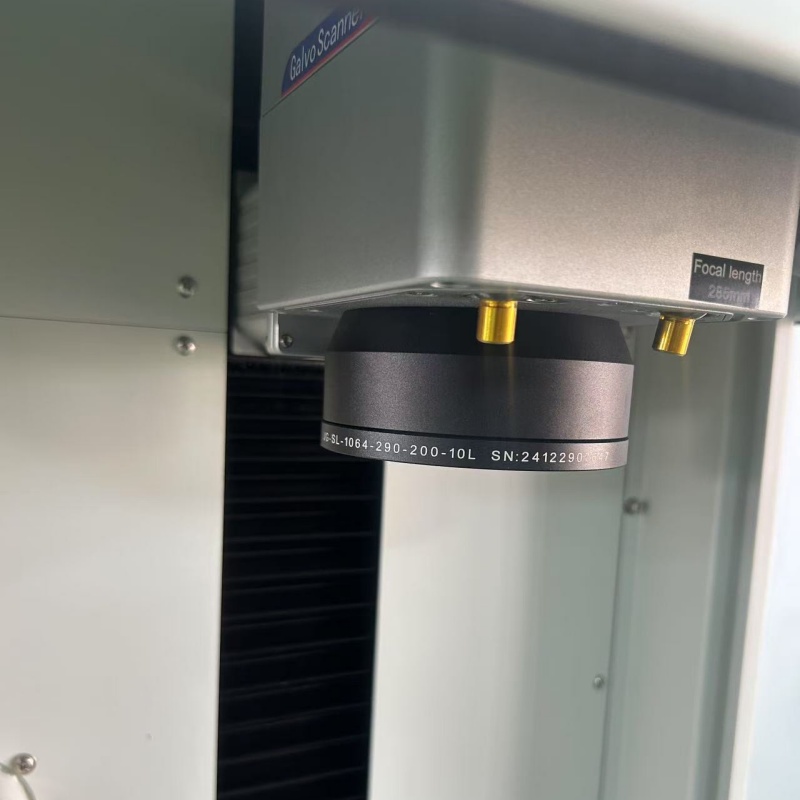

The customization capabilities of laser marking machines stem from the flexible adaptability of their core technology. Unlike traditional inkjet printing and screen printing, modern laser marking equipment can adapt to the processing needs of over 200 materials through customized settings such as spectral combinations and power adjustments. Xiangsheng Laser’s multispectral fusion vision technology is a typical example; its customized spectral schemes for special materials such as coated plastics and ceramics completely solve the industry pain point of blurred traditional markings. Even more noteworthy is the composite light source design; for example, green lasers are used for microstructure engraving on the substrate, while ultraviolet lasers optimize the marking contrast, ensuring that markings on glass maintain strong adhesion even in a -20℃ freezing environment. This breakthrough in material adaptation and customization has enabled laser marking to achieve multi-functional industrial value.

In the field of precision manufacturing, customized laser marking has become crucial for quality control. The extreme precision requirements of industries such as semiconductors and military electronics have driven laser marking technology towards the micron level. Keyence’s customized laser marking solution for Huawei HiSilicon can accurately identify ultra-small QR codes of 0.1mm × 0.1mm, maintaining a 100% resolution rate and improving yield by 0.3 percentage points compared to traditional solutions. Its developed invisible QR code technology can form encrypted markings on metal surfaces, identifiable only by a dedicated spectrometer, perfectly meeting the information security needs of the military industry. This customized solution, combined with AI visual inspection, achieves closed-loop management of “marking as inspection,” making the traceability system of precision manufacturing more reliable.

The explosive growth of the new energy and automotive industries has spurred the demand for scenario-based customization of laser marking machines. On BYD’s battery component production line, HGLaser’s customized GH-UV Vision Pro laser marking system, utilizing 3D vision technology, achieves dual detection of the height and integrity of battery tab markings, with a recognition accuracy of 99.92%. Addressing the space constraints of small and medium-sized manufacturers, the desktop customized model occupies only 0.06m³, completing precise marking with a positioning accuracy of 0.01mm, balancing efficiency and space cost. This scenario-based customization not only adapts to the needs of enterprises of different sizes but also solves the marking problem of curved workpieces such as battery casings through five-axis linkage technology, achieving a positioning accuracy of ±0.005mm.

Personalized demands from consumers are bringing laser marking into everyday life. From customized patterns on mobile phone cases to laser engraving on jewelry, the widespread adoption of lightweight laser equipment has significantly reduced the cost of “personalized customization.” In the food industry, the customized traceability function of laser marking is even more valuable. In high-end fresh milk cold-filling production lines, traditional ink-jet printing is easily corroded by condensation, while the high-contrast markings formed by customized laser solutions meet EU supply chain transparency requirements, reducing supermarket return rates by 12%. This combination of practicality and personalization in customized services makes laser marking a crucial tool for businesses to enhance their competitiveness.

The widespread adoption of customized laser marking is also inseparable from cost optimization in technology implementation. Domestic manufacturers, through independent research and development, have reduced the cost of vision modules in high-end customized equipment by 50% compared to imported models, keeping annual maintenance costs around 5,000 yuan. A nationwide service network provides 24-hour technical response, coupled with free algorithm debugging training, allowing SMEs to also enjoy the benefits of customized technology. This competitive advantage of “technology comparable to imports, but with a greater cost advantage” is driving customized laser marking from the high-end sector to widespread application.

From the intelligent upgrade of Industry 4.0 to the personalized wave in the consumer market, the customized application of laser marking machines is reshaping industrial logic. It is not only a processing tool but also a “golden key” for enterprises to achieve flexible production and precise market matching. With the deep integration of AI vision, 3D inspection, and other technologies, the customization capabilities of laser marking will leap from “adapting to needs” to “predicting needs,” creating product value that combines quality and individuality for more industries, and continuing to lead the way in intelligent manufacturing.