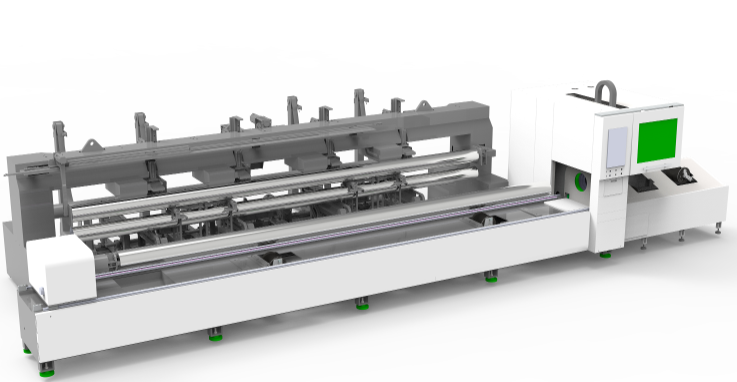

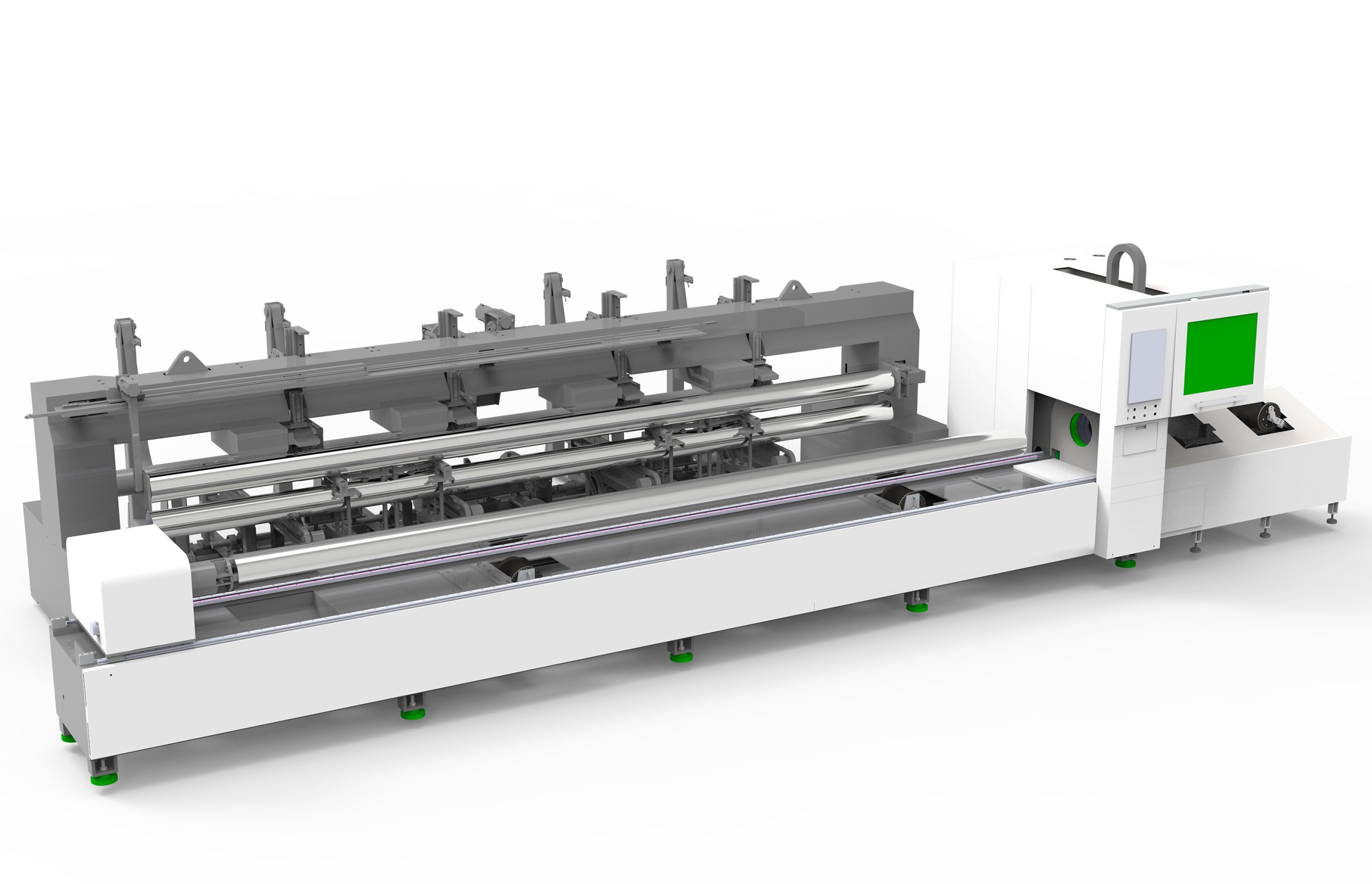

What is a Fiber Laser Pipe Cutting Machine?

A fiber laser pipe cutting machine is a high-tech system that uses a high-powered laser beam to cut through tubes or pipes made from various metals or non-metals. The process works by focusing a laser beam onto the material’s surface, heating it to the point of melting or vaporizing, and then precisely cutting the material along a programmed path. The cutting path is controlled by a computer numerical control (CNC) system, ensuring high accuracy and efficiency in the cutting process.

Key Features of FiberLaser Pipe Cutting Machines

1.High Precision Cutting

Laser pipe cutting machines offer extremely high cutting precision, with tolerances often in the micron range. This makes them ideal for producing intricate shapes, fine holes, and detailed tube profiles with exceptional accuracy.

2. Efficiency and Speed

With laser cutting, the cutting process is highly efficient and fast, reducing processing time compared to traditional cutting methods. This helps businesses increase throughput and reduce production cycles.

3. Versatility

Laser pipe cutters are capable of processing various types of tubes, including round, square, and rectangular pipes. They can handle a wide range of material thicknesses, making them suitable for a variety of industries and applications, from small custom projects to large-scale manufacturing.

4. Smooth, Clean Edges with Minimal Post-Processing

Fiber laser cutting creates smooth, clean edges with minimal thermal impact. This reduces the need for secondary finishing processes such as deburring or polishing, saving time and reducing costs.

5. High Automation

Most laser pipe cutting machines are highly automated, integrating advanced control systems that enable automatic loading and unloading of materials, as well as automated cutting paths. This reduces human intervention, improves cutting consistency, and minimizes the risk of errors.

Applications of Fiber Laser Pipe Cutting Machines

Automotive Manufacturing: In the automotive sector, laser pipe cutting is used to cut components for car frames, exhaust systems, and suspension parts with high precision and strength.

Furniture Manufacturing: Laser cutting is ideal for producing metal components for furniture, such as chair frames and table legs, with both aesthetic and structural integrity.

Construction and Architecture: Laser cutting machines are commonly used to process metal tubes for structural applications, such as scaffolding and architectural frameworks, providing both strength and visual appeal.

Aerospace Industry: The aerospace industry relies on laser tube cutting to create precision parts for aircraft, where the exactness and reliability of components are critical.

General Machinery: Laser pipe cutters are used to produce various machine parts, including housings, frames, and pipes for mechanical systems.

Advantages of Laser Pipe Cutting Machines

1.Energy Efficiency

Laser pipe cutting machines are energy-efficient compared to traditional cutting methods. Since they use a focused laser beam rather than mechanical tools, there is less material waste and minimal energy consumption during the process, making them more environmentally friendly.

2.Reduced Labor Costs

With their high degree of automation, laser pipe cutting machines reduce the need for manual labor, which helps lower operational costs while improving safety and precision.

3.Customization and Flexibility

Fiber laser pipe cutting allows for precise and flexible cutting, enabling customization for small or complex batch production. This makes it ideal for industries that require non-standard shapes and intricate designs.

4.Fast Processing with High Accuracy

Laser cutting can achieve both high cutting speeds and precise accuracy, making it an ideal solution for mass production or projects that require quick turnaround times without sacrificing quality.

Conclusion

Fiber Laser pipe cutting machines represent a game-changing technology for modern manufacturing. With their ability to provide high precision, fast processing times, and the flexibility to handle a wide range of tube materials and shapes, they have become an indispensable tool in industries ranging from automotive to aerospace. As technology continues to advance, the role of laser tube cutting machines will only grow, providing manufacturers with greater productivity, reduced costs, and a competitive edge in today’s fast-paced industrial landscape.