In the field of surface treatment, sandblasting is widely used in decorative and industrial applications due to its anti-slip, wear-resistant, and matte finish. Traditional sandblasting relies on processes like sandblasting and chemical etching, which suffer from low precision, high pollution, and high material consumption. The emergence of laser sandblasting and engraving machines, with their advantages of “non-contact processing,” “high-precision control,” and “environmental efficiency,” has redefined the sandblasting process, creating a richer range of sandblasting finishes for a variety of materials, including metal, glass, and stone.

- 1.The Core Principle of Laser Sandblasting and Engraving Machines: Precise “Sand” Creation

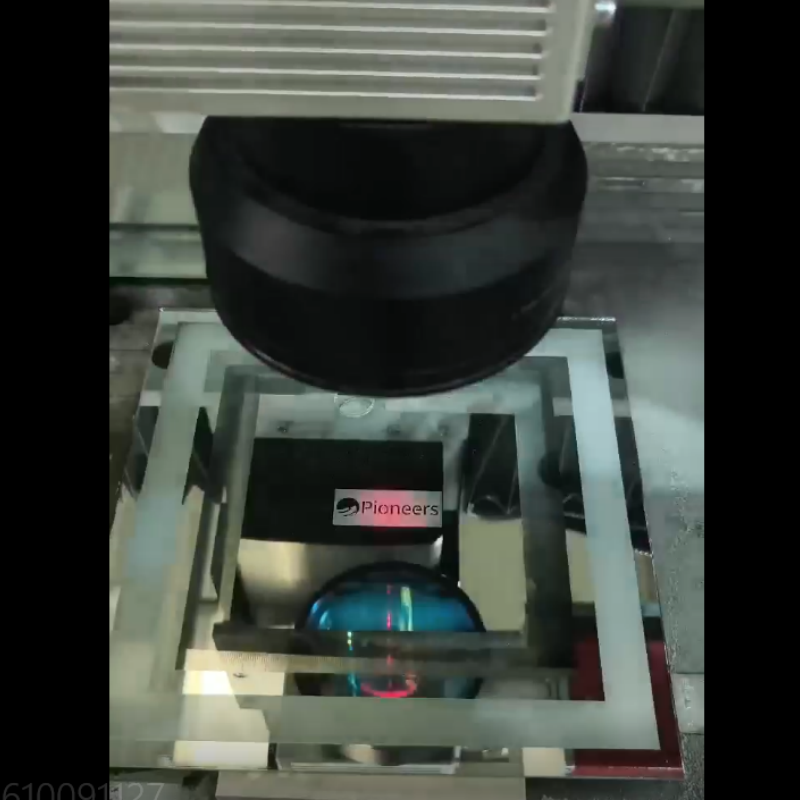

Laser sandblasting and engraving machines do not rely on physical abrasive impact with the material surface. Instead, they use controlled ablation with a high-energy laser beam to create uniform, fine microscopic pits on the material surface, simulating the rough texture of traditional sandblasting. Their operating logic can be divided into three key steps:

First, “laser energy control.” The specialized lasers (such as fiber lasers or UV lasers) onboard these machines can output pulsed laser light. The laser’s energy density and pulse frequency are controlled by a numerical control system. Energy density determines pit depth (higher energy results in deeper pits and a rougher finish), while pulse frequency controls pit density (higher frequency results in denser pits and a finer finish). For example, to create a light sandblasting effect on glass, the laser energy and frequency are reduced, resulting in sparse, shallow pits. To create a non-slip finish on metal parts, the energy and frequency are increased to create dense, deep pits.

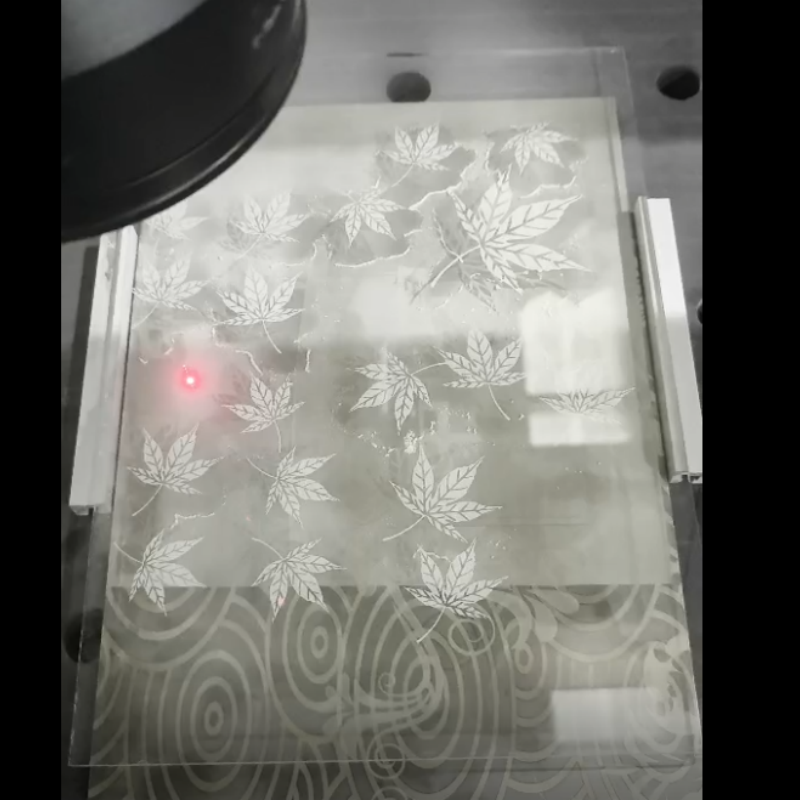

The second key is path planning and scanning. Unlike traditional sandblasting, which covers a large area, laser sandblasting and engraving machines use a galvanometer system to plan the laser scanning path according to a pre-set pattern (such as textures, text, or logos). The laser beam moves across the material surface with micron-level precision, creating a sandblasted surface only in designated areas, achieving precise zoning between “localized sandblasting” and “smooth” surfaces. For example, on a stainless steel water cup, the main body can be sandblasted, while the rim and logo area remain smooth, achieving both aesthetic appeal and practicality. Finally, there’s “material adaptation.” The machine adjusts laser parameters based on different material properties to avoid material damage. When processing brittle materials like glass and stone, the “low-energy, multiple-scan” mode is used to gradually ablate and reduce thermal stress, preventing material breakage. When processing metals like aluminum alloys and copper, the laser energy can be increased, and the auxiliary air blowing system can be activated to promptly remove molten debris and prevent residual impurities on the sanded surface.

- 2. Key Points for Laser Sandblasting and Engraving: Efficient and High-Quality

To achieve ideal sanded surfaces with a laser sandblasting and engraving machine, three core operational steps must be mastered:

(1) Material Pretreatment: Clearing Processing Obstacles

Before processing, clean the surface according to the material type. For metals, wipe with alcohol to remove oil and oxide layers to prevent uneven laser reflection and uneven sanding. For glass, use a dust-free cloth dipped in a specialized cleaner to remove fingerprints and prevent stains after processing. For curved or irregularly shaped workpieces (such as glass vases and metal pipes), a custom fixture is required to ensure the workpiece remains parallel to the laser scanning plane, preventing uneven sanding thickness caused by tilting the workpiece.

(2) Parameter Adjustment: Matching Sanding Requirements

Parameter settings directly determine the sanding surface quality. Three key parameters require adjustment: First, “Laser Power.” Choose 5-10W for light sanding on glass, and 20-30W for deep sanding on metal for a non-slip finish. Second, “Scanning Pitch.” A spacing of 0.01mm creates a fine sanding surface (such as decorative panels), while a spacing of 0.03mm is suitable for rough, non-slip sanding (such as stair treads). Third, “Scanning Speed.” Too fast a speed can result in a sparse sanding surface, while too slow a speed can cause the material to overheat and deform. The speed is typically controlled between 500-1500mm/s. After adjustment, test engraving on a sample of the same material to observe the sanding surface uniformity, and then fine-tune the parameters based on the desired results. (III) Post-Processing: Optimizing the Sand Surface Texture

After processing, metal workpieces should be blown away surface debris with compressed air. If necessary, lightly sand the edges with fine sandpaper to eliminate burrs. Glass workpieces can be polished to enhance the surface’s fineness and light transmittance. To further enhance the durability of the sand surface, metal workpieces can be sprayed with a protective coating, while glass workpieces can be tempered to extend the life of the sand surface.

- 3. Application Scenarios of Laser Sandblasting and Engraving Machines: Expanding the Boundaries of Sandblasting

With their precision and flexibility, laser sandblasting and engraving machines have unlocked new applications for sandblasting in multiple fields:

In architectural decoration, they can create gradient sandblasting patterns on glass curtain walls and stone countertops, replacing traditional etching processes and creating decorative surfaces that combine privacy protection with an artistic aesthetic. In household goods, laser sandblasting is used to create a non-slip surface on the bottom of stainless steel sinks, preventing tableware from slipping. In industrial components, laser sandblasting creates a non-slip surface on automotive pedals and mechanical equipment consoles, enhancing safety. In the cultural and creative industry, laser sandblasting can create partial sandblasting logos on wooden plaques and ceramic tea sets, adding a touch of sophistication to these products.

Compared to traditional sandblasting, laser sandblasting and engraving machines require no abrasive, reducing environmental pollution. They also enable personalized pattern customization, breaking the limitations of traditional sandblasting, which often results in a single texture. With technological development, laser sandblasting engraving machines will be upgraded to “multi-material compatibility” and “intelligent parameter matching” in the future, further expanding the application boundaries of material sandblasting technology and bringing dual improvements in quality and efficiency to more industries.