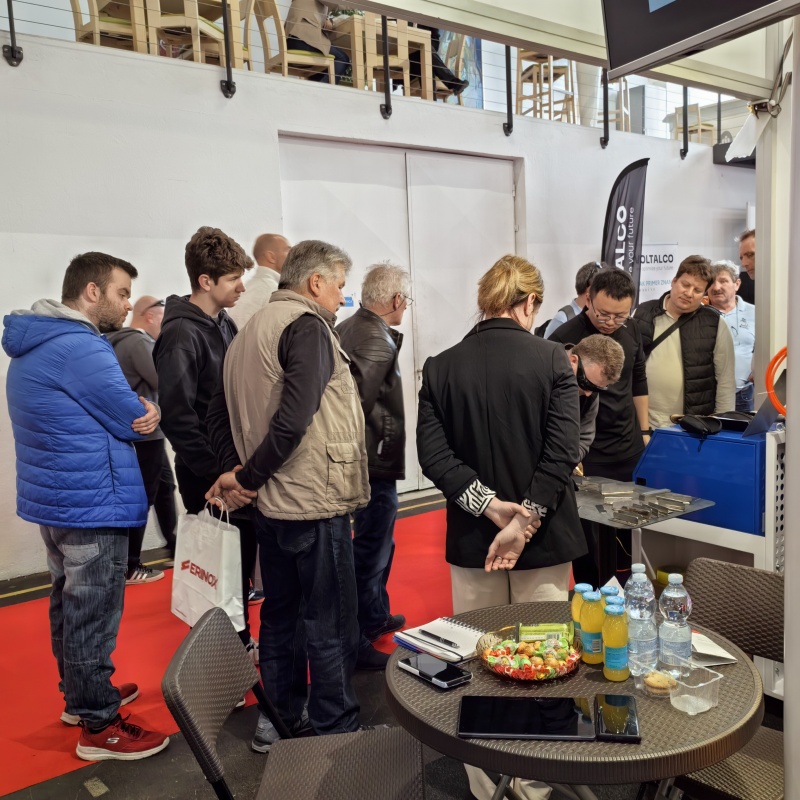

At the recent industry event, many advanced equipment gathered together, among which handheld welding machines, laser cutting machines and smart mirror sandblasting machines became the focus of the whole venue, attracting the attention of countless exhibitors.

Handheld welding machines are favored for their excellent performance and convenience. This new generation of laser welding products adopts an integrated design, which is not only beautiful in appearance, but also stable in performance. It is easy to install and easy to operate, and even novices can get started quickly. In the on-site demonstration, its fast welding speed and high efficiency are amazing. The welding of complex workpieces was completed in a short time, and the welds were beautiful, without weld marks and discoloration, and no post-grinding was required, which greatly saved processing time and cost. It also has multiple safety alarms, and automatically locks the light after removing the workpiece, which is extremely safe. A wide range of applications, from kitchen utensils to automobile manufacturing and other industries, have given many companies new hope for improving production efficiency.

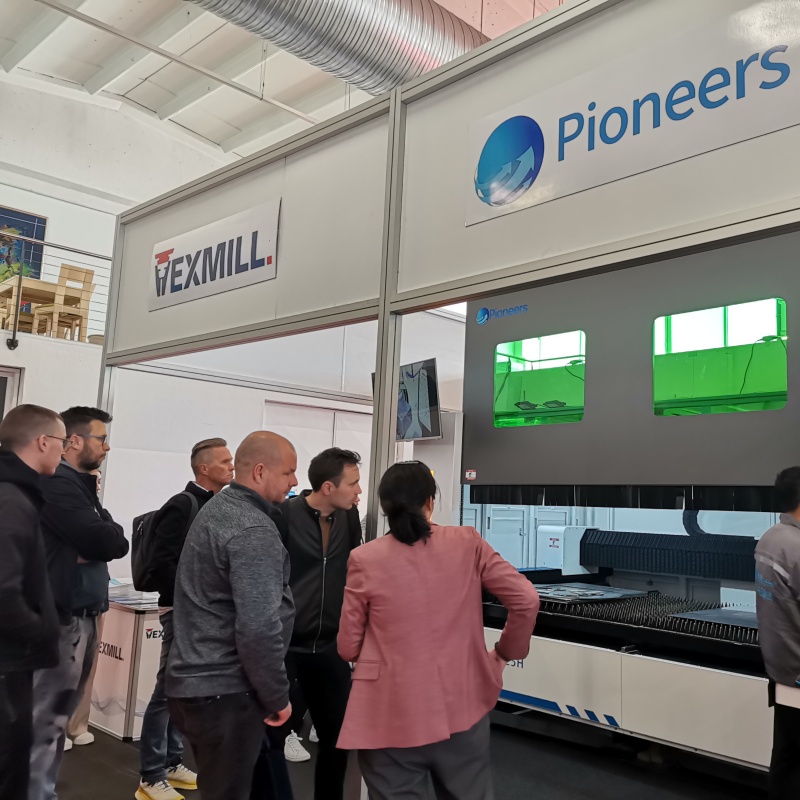

Laser cutting machines are also very popular. Its cutting accuracy is extremely high, and it can perform fine processing on various metal and non-metal materials. In the demonstration area of the exhibition, the cutting process is smooth and stable, and the cutting edges are smooth and neat. Whether it is a thin plate or a thick plate, it can be easily handled. The efficient cutting speed greatly improves the production efficiency and attracts many practitioners in the sheet metal processing, advertising production and other industries to stop and consult. Its advanced control system and stable performance provide a strong guarantee for enterprises to achieve high-precision and high-efficiency production.

The smart mirror sandblasting machine has brought innovation to the production and manufacturing of smart mirrors. It successfully solves the cumbersome processes of film pasting, engraving, and tearing in the traditional production process, as well as the drawbacks of easy scratches and defective products. Using laser etching, only one process is needed to accurately make the graphics and switch button parts of the light-transmitting parts, and the effect is beautiful and high-end. It is reported that the use of this equipment can increase the original daily production capacity of the factory by 2-3 times, greatly reducing the production cost of the enterprise. During the on-site demonstration, its efficient processing process and excellent finished product effect made the heads of smart mirror production companies show great interest.

These three devices shined at the exhibition. With their respective advantages, they provided new directions and solutions for the development of related industries. It is no wonder that they became the focus of everyone’s attention and led the new trend of the industry.