In laser etching scenarios, Roman numerals, with their retro and elegant visual style, are often used in custom needs such as clock dials, jewelry nameplates, and furniture logos. Based on the core logic of the previous “3-Step Quick Start” guide, this section will focus on the characteristics of Roman numeral etching, supplement design specifications, parameter adaptation, and practical skills to help beginners efficiently complete Roman numeral etching.

I. Special Preparation Before Roman Numeral Etching

Compared with ordinary text, the character structure of Roman numerals (such as the line proportions of “I”, “V”, “X”) has higher requirements for etching accuracy. Two key points need to be emphasized in the pre-preparation stage:

1. Standardized Processing of Design Files

The etching effect of Roman numerals depends on clear vector files to avoid character distortion after etching due to blurry fonts. It is recommended to prepare files according to the following standards:

- Font Selection: Priority should be given to serif Roman numeral fonts (such as Times New Roman, Trajan Pro). These fonts have layered line thicknesses and present a more three-dimensional effect after etching. Avoid overly artistic fonts (such as distorted or connected-stroke styles), which may lead to unclear etching of thin lines.

- File Format: The SVG vector format must be used. If only PNG/JPG bitmap files are available, they need to be converted to vector graphics using software (such as CorelDRAW, Inkscape) to ensure no jagged edges on character outlines when enlarged.

- Character Size and Spacing: Adjust according to the material size. For example, when etching the Roman numeral “XII” on a clock dial with a diameter of 3cm, the height of a single character is recommended to be set to 5-8mm, and the character spacing should be maintained at 2-3mm to avoid overcrowding or dispersion.

2. Adaptation Between Materials and Laser Types

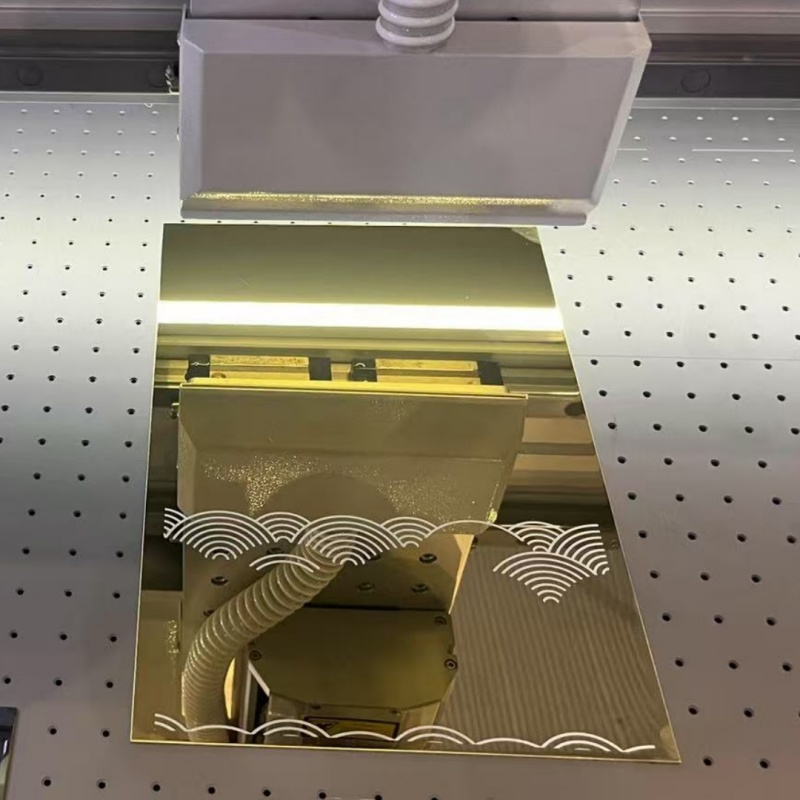

Roman numerals are commonly used on materials such as metal, glass, and acrylic. The corresponding laser type should be selected based on the material properties:

- Metal Materials (Stainless Steel, Brass): Suitable for fiber lasers. The character lines can be as thin as 0.1mm, making them ideal for creating exquisite jewelry nameplates (such as Roman numeral dates on the inner wall of a ring).

- Glass/Acrylic: Suitable for CO₂ lasers. The “shallow engraving” mode can be selected during etching (power 30%-40%, speed 600mm/s) to form translucent Roman numeral logos, which are often used on furniture decorative panels.

- Wooden Materials: Suitable for CO₂ lasers. The “deep engraving” mode is recommended (power 50%-60%, speed 400mm/s) to make the Roman numeral lines more prominent, which is suitable for retro-style wooden clock dials.

II. Parameter Optimization for Roman Numeral Etching

The difference in line thickness of Roman numerals (e.g., “I” is a thin line, “M” is a thick line) requires targeted parameter adjustment to avoid problems such as “broken thin lines” and “burnt thick lines”. The following are scenario-specific parameter references:

1. Metal Materials (Fiber Laser)

Character Line Thickness | Power | Speed | Resolution | Application Scenario |

0.1-0.3mm (Thin Line) | 60%-70% | 300-400mm/s | 600DPI | Jewelry Nameplates, Watch Dials |

0.4-0.6mm (Thick Line) | 75%-85% | 200-300mm/s | 600DPI | Metal Door Plates, Commemorative Coins |

Note: When etching thin-line Roman numerals, the “line optimization” function in the software must be enabled to avoid line breaks caused by frequent starts and stops of the laser head. For oxidizable materials such as brass, anti-rust oil can be applied to protect the characters after etching.

2. Glass/Acrylic (CO₂ Laser)

Etching Effect | Power | Speed | Resolution | Operation Tips |

Translucent Shallow Engraving | 30%-40% | 500-600mm/s | 300DPI | Wipe the surface with alcohol after etching to remove residual powder |

Opaque Deep Engraving | 50%-60% | 300-400mm/s | 450DPI | Etch in 2 passes (30% power for the first pass, 20% power for the second pass) to avoid material cracking |

3. Wooden Materials (CO₂ Laser)

Wood Type | Power | Speed | Resolution | Special Treatment |

Soft Wood (Pine, Fir) | 45%-55% | 400-500mm/s | 300DPI | Apply a thin layer of wax on the wood surface before etching to reduce smoke adhesion |

Hard Wood (Walnut, Oak) | 55%-65% | 300-400mm/s | 450DPI | Choose areas with straight wood grain to avoid uneven lines caused by intersecting grains |

III. Practical Steps for Roman Numeral Etching

Based on the previous “3-Step Practical Process”, the following key operational details are supplemented for the particularity of Roman numerals:

1. Positioning and Calibration: Ensure Character Symmetry

Roman numerals are often used in symmetrical designs (such as 12 characters on a clock dial). When positioning, attention should be paid to:

- Use the “guide line” function in the software to draw a cross line at the center of the material. Align the Roman numerals “XII” and “VI” with the vertical line, and “III” and “IX” with the horizontal line to ensure uniform character distribution.

- For circular materials (such as dials), select the “circular array” function in the software, enter the number of characters (e.g., 12), and the Roman numerals will be automatically and evenly distributed to avoid errors caused by manual adjustment.

2. Preview and Testing: Focus on Checking Thin Lines

Before starting etching, test the thin-line part of Roman numerals with waste materials:

- Prepare a piece of waste material of the same type as the finished product, etch a single thin-line character (such as “I”, “II”), and observe whether the lines are complete and free of breaks.

- If thin-line breaks occur, appropriately reduce the speed (e.g., from 400mm/s to 350mm/s) or increase the power (e.g., from 60% to 65%), and test again until the lines are clear.

3. Finishing and Processing: Enhance Character Texture

After etching is completed, perform finishing according to the material properties:

- Metal Materials: Gently polish the edges of the characters with fine sandpaper to remove burrs, then wipe with a polishing cloth to improve glossiness.

- Glass/Acrylic: Wipe the character surface with a non-woven cloth dipped in a small amount of glass cleaner to make the translucent effect more uniform.

- Wooden Materials: Clean the wood chips inside the characters with a brush, then apply wood wax oil to protect the wood and make the character color darker.

IV. Common Problems and Solutions

Problem Phenomenon | Possible Cause | Solution |

Broken Thin Lines of Roman Numerals | Insufficient Power, Excessive Speed | Increase power by 5%-10%, reduce speed by 50-100mm/s |

Burnt Edges of Thick-Line Characters | Excessive Power, Flammable Material | Reduce power by 10%-15%, place a high-temperature resistant pad under the material |

Character Position Deviation | Unfixed Material, Incorrect Guide Line Calibration | Re-fix the material with clamps and re-set the guide lines for alignment |

Blurry and Jagged Characters | Insufficient Resolution, Bitmap File | Increase resolution to 600DPI, convert bitmap to SVG vector graphics |

After mastering the etching skills of Roman numerals, you can further expand the application scenarios, such as etching Roman numeral years on wine bottle stoppers and Roman numeral page numbers on notebook covers. As long as you optimize the parameters according to the material properties, beginners can also create Roman numeral etching works that combine beauty and precision.