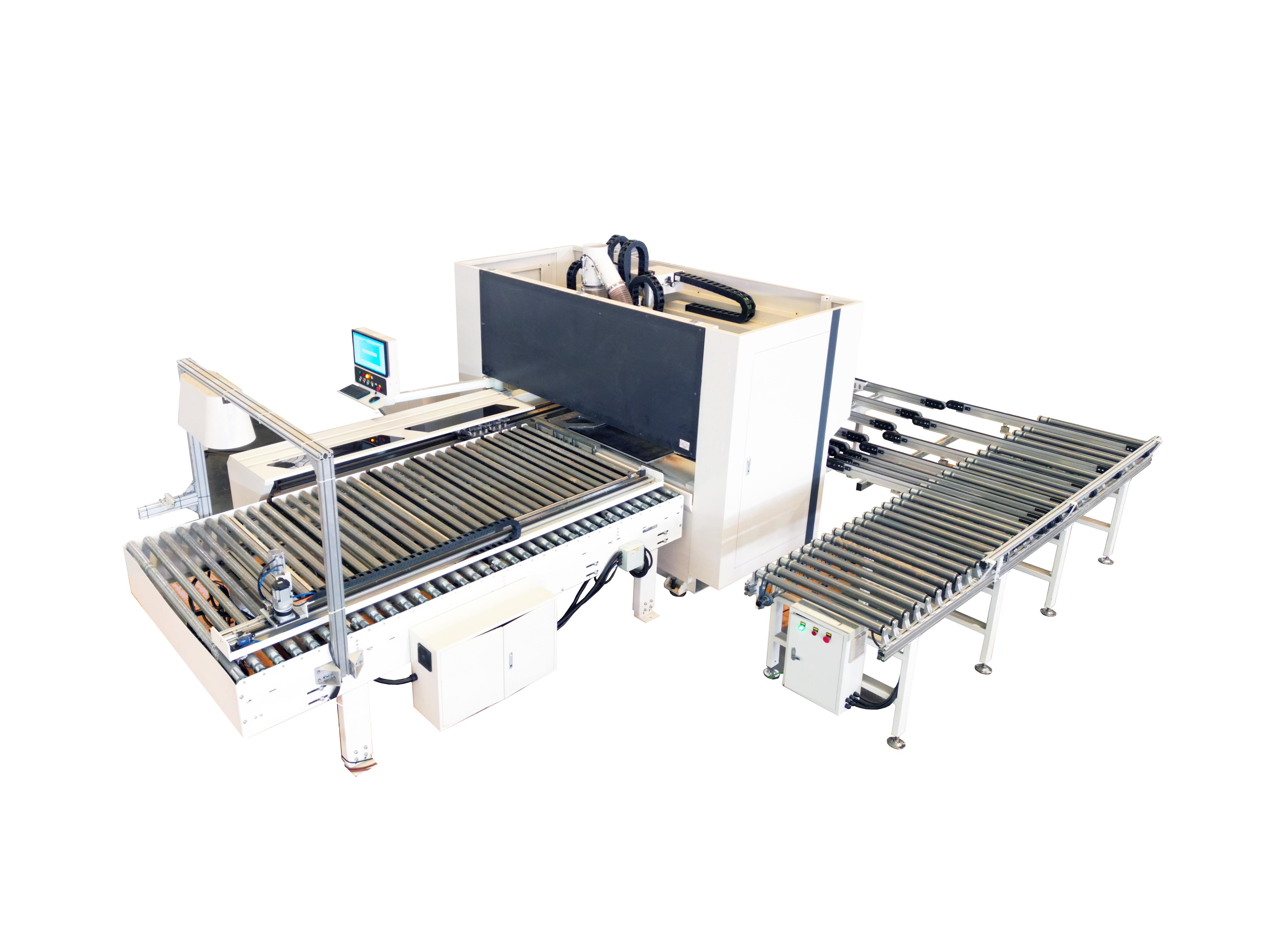

CNC six side drilling automatically identifies the plate processing information through wireless scanning code, locates at one time, and automatically feeds and processes all holes and slots without turning over the plate.

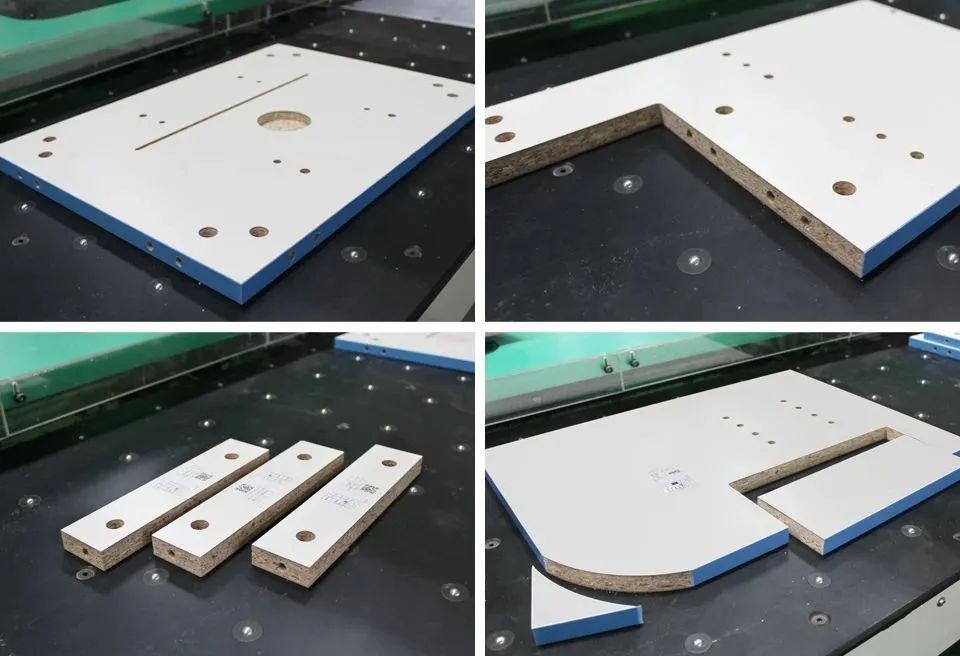

Automatic tool change six-sided drilling is mainly used in the production of panel furniture drilling and grooving, the equipment can not only meet the common panel furniture two-in-one, three-in-one, woodeasy, Lamino, etc. (part of the process needs to be equipped with Angle head) connector installation hole slot processing, but also can realize the slotting, milling and shaped cutting processing of plate parts

Six side drilling body adopts thickness steel tube welded, annealing aging, shot blasting and sandblasting treatment, five-sided milling processing, the bbody has high stability, long life and high precision.

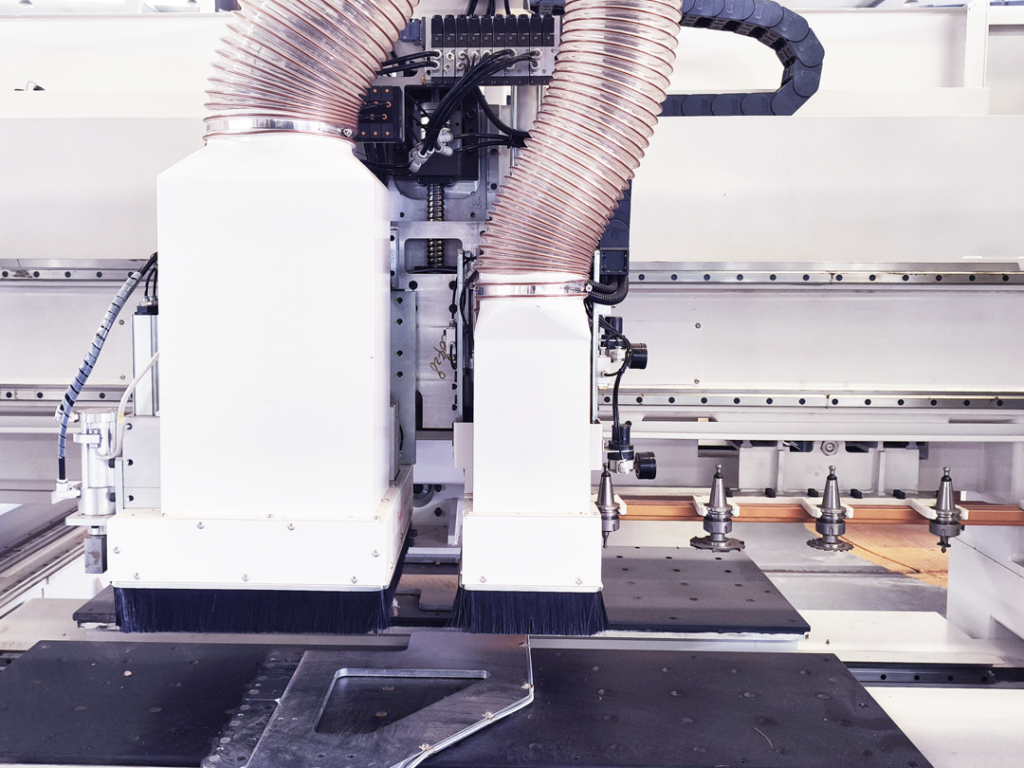

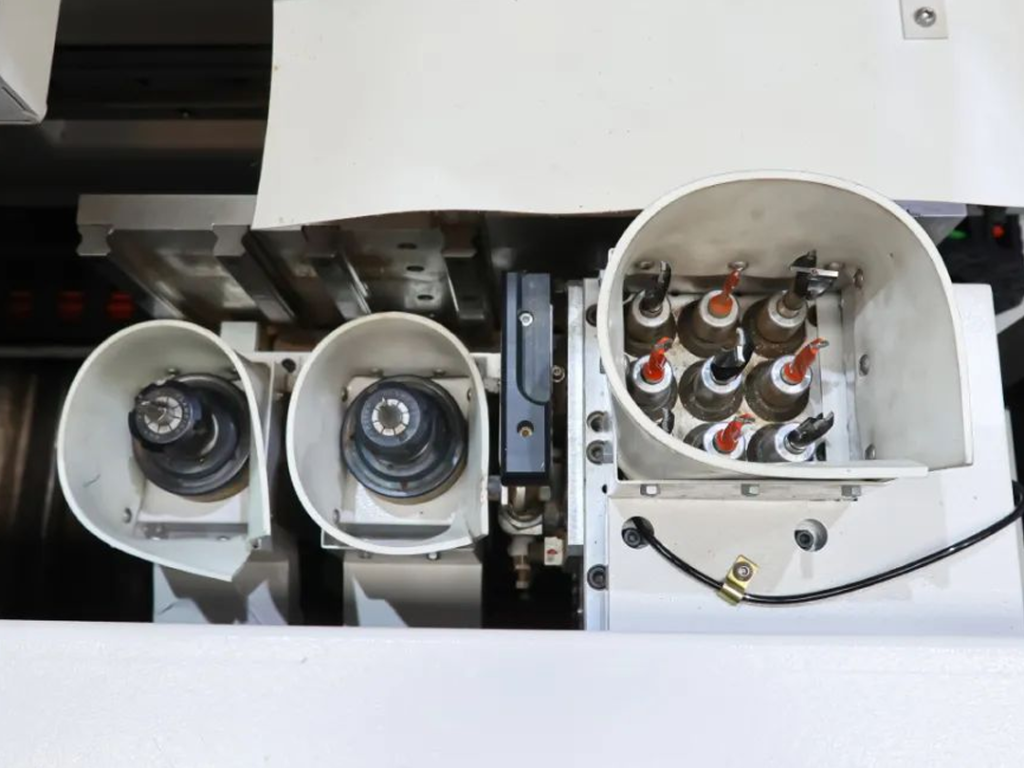

Top drilling bank: 12 vertical +8 horizontal

6KW automatic tool changing spindle

Bottom drilling bank: 9 vertical down

3.5KW manual tool change spindle ×2.

Automatic plate fixing mechanism, the size of the plate processing wordless, high processing efficiency.

Six side drilling is equipped with 6-position in-line tool library to meet more processes and improve production efficiency.

Fixed automatic tool setting instrument, automatic tool setting after automatic tool change, improve efficiency and machining accuracy.

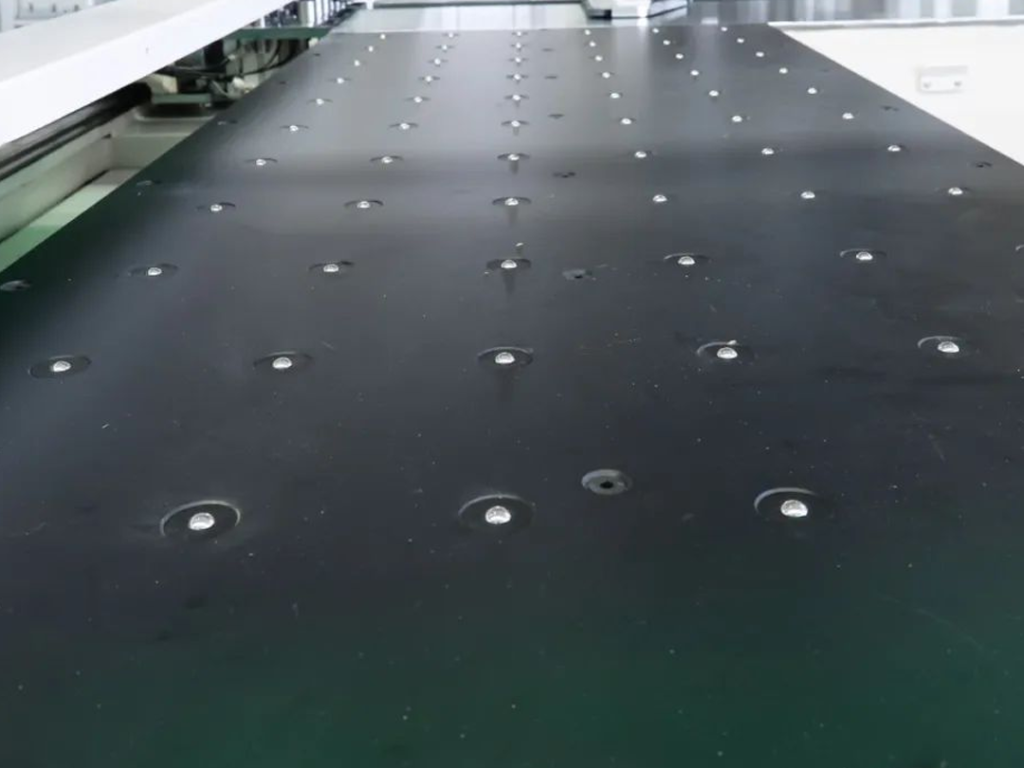

Increased air float bead anti-double special table, the plate is not easy to run off, the surface is not easy to scratch.

The U-shaped pneumatic clamp can quickly position and support the plate, and the holding force is uniform, ensuring the stability of the plate during high-speed drilling and cutting, and improving production efficiency.

| Working stroke | X axis | 3000mm | Up spindle power | 3.5KW |

| Y axis | 1500mm | Bottom spindle power | 3.5KW | |

| Z axis | 200mm | Reducer | Japan Shimpo | |

| Max.Feed rate | X axis speed | 130m/min | Gear Rack | GerGermany Ronnie ground level |

| Y axis speed | 85m/min | Ballscrew | Taiwan TBI | |

| Z axis speed | 25m/min | Inverter | HPMONT | |

| Min. Panel size | 45x180mm | Main electrical element | France Schneider | |

| Max. Panel size | 1220mm(panel width) | Main pneumatic element | Taiwan Airtac | |

| Upper drill unit | 12V+8Horizontal(2.2KW) | Wireless scanner | ZEBRA | |

| Lower drill unit | 9(3*3)Vertical(2.2KW) | Working table | Air-floated with beads+steel board | |

| Dimension (width*length*height) | 2650*5200*2600mm | Weight | 4000kg | |

| Working voltage, pressure, power | 3PH AC380V/50Hz、≥0.65Mpa、18.2KW(without dust collect) | |||

Q : What is an automatic tool changing CNC six-sided drill?

R : Six side drilling machine widely used in cabinet working factory, it can give efficient work and precision hole. If choose ATC function,It can can realize the slotting, milling and shaped cutting processing of plate parts

phone: +8613791007598

[email protected]