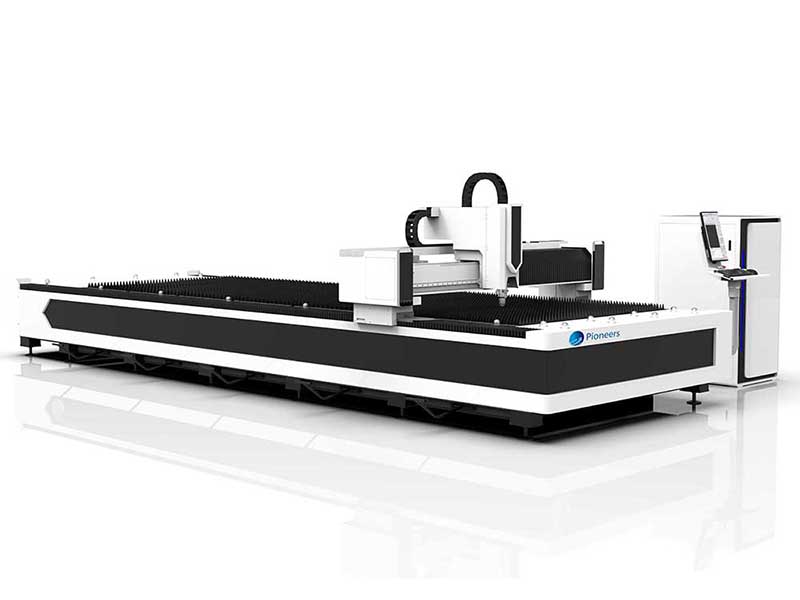

Open table single platform fiber laser cutter is a model for flexible using of sheet metal processing. Apply for 3 meter and 6 meter sheets, with high speed servomotor system, this machine have a high efficiency.

Fiber laser cutting machines represent a cutting-edge technology in the field of industrial manufacturing. These machines utilize a high-powered, coherent light beam generated by a fiber laser to cut materials with exceptional precision and efficiency.

Fiber laser cutting machines offer several advantages over traditional cutting methods. They provide higher cutting speeds, improved precision, and the ability to cut a wide range of materials, including metals, plastics, and composites. Additionally, these machines require less maintenance and have a longer operational lifespan compared to other cutting technologies.

The versatility of fiber laser cutting machines makes them suitable for various applications in industries such as automotive, aerospace, electronics, and medical device manufacturing. They enable manufacturers to achieve high productivity, superior product quality, and cost savings through efficient material utilization.

| No. | ITEM | PL 2513/3015/4020/6020 |

| 1 | Machine Travel(X*Y*Z) | 1300*2500*100/1500*3000*100/2000*4000*100/2000*6000*100 |

| 2 | Laser Source | Raycus/IPG |

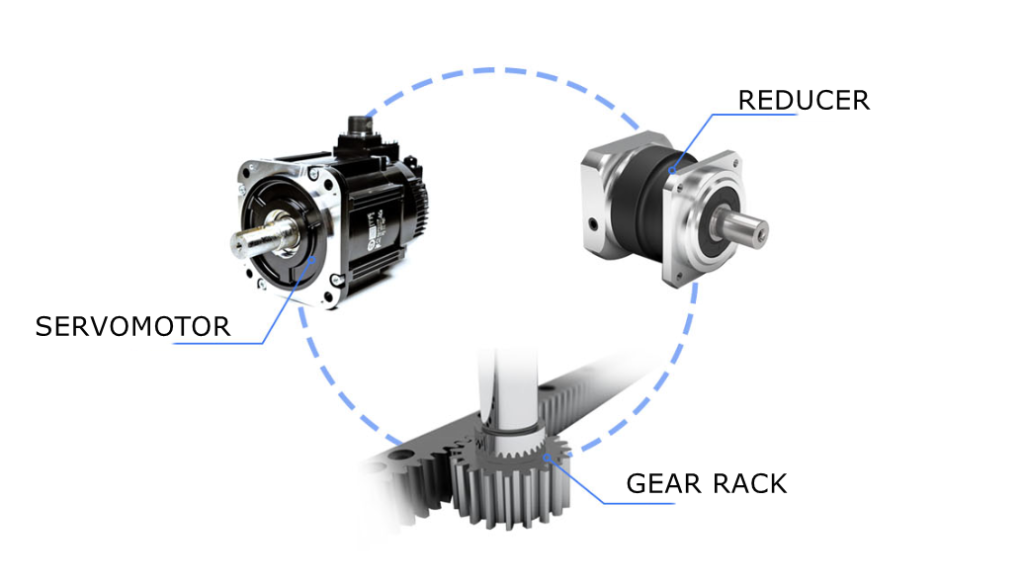

| 3 | Transmission System | Helical Rack(YYC) |

| Linear Guides(HIWIN) | ||

| 4 | Motors & Drivers | Yaskawa Servo System |

| 5 | Max Ideal Speed | 80M/Min |

| 6 | Max Acceleration | 1.2G |

| 7 | Positioning Accuracy | ±0.03mm |

| 8 | Re-Position Accuracy | ±0.02mm |

| 9 | Lubrication System | One Touch Automatic Lubrication |

| 10 | Pressure Valves | High-pressure(N₂,Air):2.5MPa(AirTac) |

| Low-pressure(O₂):1MPa(SMC) | ||

| 11 | Electrical Components | Schneider |

| 12 | Gross Power | <23KW |

| 13 | Power Supply | Three-phase 380V/50Hz/60Hz |

| 14 | Gross Weight | 2500Kg |

High precision transmission system, servomotor with grinding rack provides high precision cutting results.

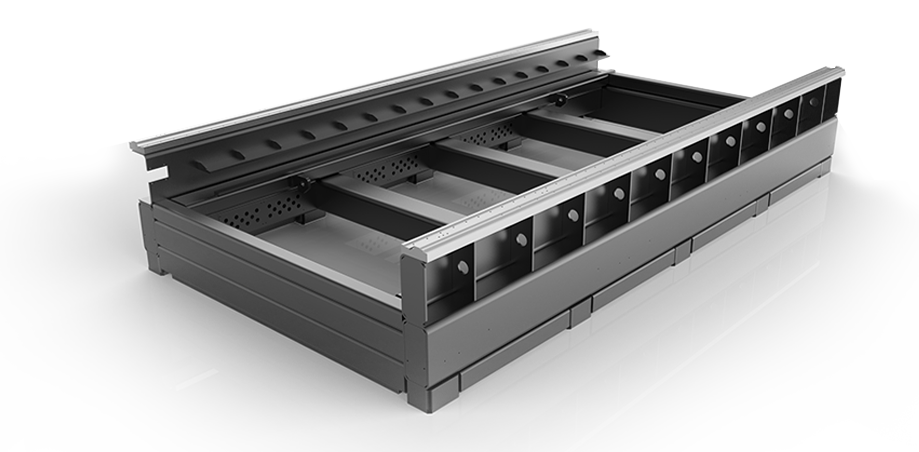

Heavy duty tube welded machine body, zoned smoke exhaustion system, machine body annealed and heat treated to reduce the stress.

Professional bus control system. In-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks.

When your cutting materials is not very heavy which can be loaded and uploaded manually, or you have limited working area, you can choose single platform fiber laser cutter.

A single platform machine can install up to a 20KW laser source, which can cut 50mm carbon steel, 35mm stainless steel. But for safety and environmental protection reasons, we highly recommend you choose fully enclosed model.

We provide professional online training and E-manual along with the machine. No matter you used the machine or not, you have no worries becoming a professional operator.

phone: +8613791007598

[email protected]