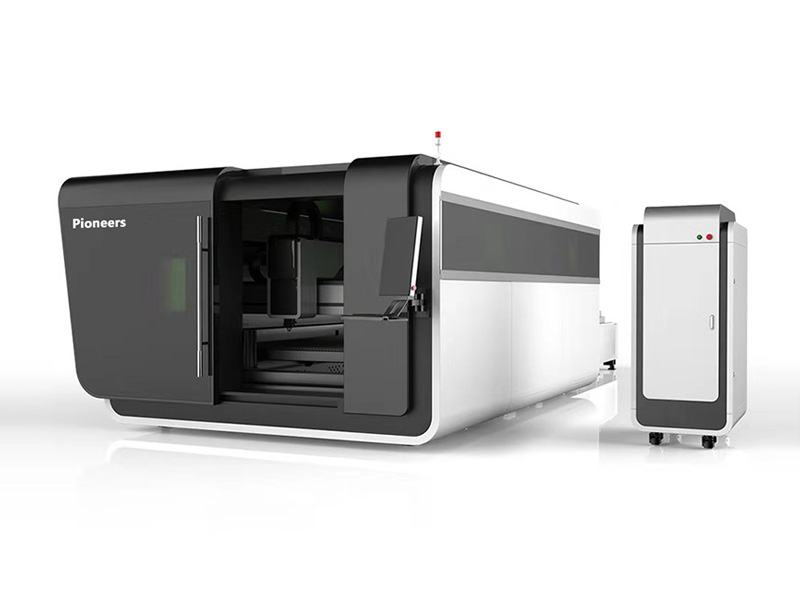

¡øEnclosed cover with EU standard protective glass, which can protect your employees better

¡øHeavy duty machine body with exchange platform

¡øHigh cutting efficiency and low energy consumption

¡øFlexible configuration, support custimization

| Ipg laser source Long Service Life The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely. Stable Cutting Performance Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation. |

LaserHead: Germany Precitec laser head Advantages: Auto-focus --High Precision: without manual, zero fault. --High Effectiveness: Without manual,Save time. --High Safety: Anti-collision design, height adjustment high sensitivity Without Manual Focusing. The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting |  |

| Safety and no pollution With a fully enclosed design. The observation window adopts an European CE Standard laser protective glass. The smoke produced by cutting can be filtrated inside, it¡¯s non-polluting and environmentally friendly. |

Exchanging platform It adopts an up and down exchange platform,and the converter is responsible for controlling the exchanging motor.The machine is able to finish the platform exchanging within 15-17s. |  |

| Monitored control system In the processing process,each dead corner area can be monitored at any time,the process can be controlled. High definition intelligent monitoring system,remote alarm,there is no danger in operation |

Plate welding heavy work bed Annealed And Heat Treated Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed. |  |

| Voltage stabilizer(optional )-50kva Its function is to stabilize the power supply voltage which fluctuates greatly and fails to meet the requirements of electrical equipment within its set value range, so that all kinds of circuits or electrical equipment can work normally under rated working voltage. |

Model | PLF3015GA | |||

Laser power | 1000-12000W | |||

Repeated positioning accuracy | ±0.02mm | |||

Maximum speed | 150m/min | |||

Max acceleration | 2G | |||

Working area | 3000*1500mm | |||

Voltage and frequency | 380V/50HZ/60HZ | |||

Machine checking team to check every parts follow the purchase order after sales done, double check to make sure every parts all will ship machine together ,and take pics save in the machine folder.

Wrap all the machine parts with bubble film & plastic film. Insert necessary anti friction & collision pad at the corner.Set all the small parts on the machine bed to save space.

Machines are packed onto wooden pallets and loaded into containers

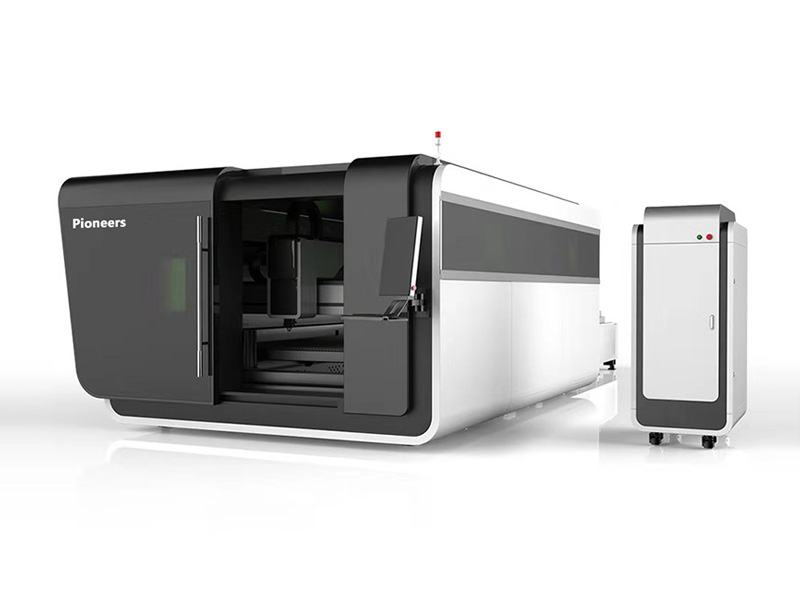

¡øEnclosed cover with EU standard protective glass, which can protect your employees better

¡øHeavy duty machine body with exchange platform

¡øHigh cutting efficiency and low energy consumption

¡øFlexible configuration, support custimization

| Ipg laser source Long Service Life The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely. Stable Cutting Performance Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation. |

LaserHead: Germany Precitec laser head Advantages: Auto-focus --High Precision: without manual, zero fault. --High Effectiveness: Without manual,Save time. --High Safety: Anti-collision design, height adjustment high sensitivity Without Manual Focusing. The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting |  |

| Safety and no pollution With a fully enclosed design. The observation window adopts an European CE Standard laser protective glass. The smoke produced by cutting can be filtrated inside, it¡¯s non-polluting and environmentally friendly. |

Exchanging platform It adopts an up and down exchange platform,and the converter is responsible for controlling the exchanging motor.The machine is able to finish the platform exchanging within 15-17s. |  |

| Monitored control system In the processing process,each dead corner area can be monitored at any time,the process can be controlled. High definition intelligent monitoring system,remote alarm,there is no danger in operation |

Plate welding heavy work bed Annealed And Heat Treated Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed. |  |

| Voltage stabilizer(optional )-50kva Its function is to stabilize the power supply voltage which fluctuates greatly and fails to meet the requirements of electrical equipment within its set value range, so that all kinds of circuits or electrical equipment can work normally under rated working voltage. |

Model | PLF3015GA | |||

Laser power | 1000-12000W | |||

Repeated positioning accuracy | ±0.02mm | |||

Maximum speed | 150m/min | |||

Max acceleration | 2G | |||

Working area | 3000*1500mm | |||

Voltage and frequency | 380V/50HZ/60HZ | |||

Machine checking team to check every parts follow the purchase order after sales done, double check to make sure every parts all will ship machine together ,and take pics save in the machine folder.

Wrap all the machine parts with bubble film & plastic film. Insert necessary anti friction & collision pad at the corner.Set all the small parts on the machine bed to save space.

Machines are packed onto wooden pallets and loaded into containers

phone: +48 501 944 934

[email protected]